High Quality 6063 Aluminum Coil Manufacture for Coated Aluminium Coils for ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Coated Aluminium Coils for ACP With High Quality

Coated Aluminium Coils for ACP is processed through the technics of roller coating and baking with precise polyester paints. Its color is glossy and with variety of colors enabling you to choose easily. Chromatic aberration is small, impact resistance is strong and easy to be processed, and all its performance has reached or surpassed the national criteria.

Coated Aluminium Coils for ACP are widely used in indoor and door decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters, home appliances, decoration in and out of autos and boats.

2. Main Features of Coated Aluminium Coils for ACP With High Quality

• Light Weight

• High Flatness

• Protecting Environment

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

3. Coated Aluminium Coils for ACP With High Quality Images

4. Specification of Coated Aluminium Coils for ACP With High Quality

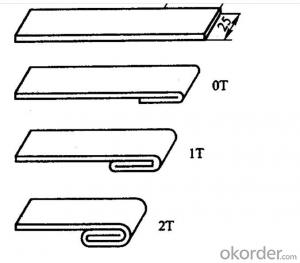

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥2H |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥2H |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥2H |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥2H |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB |

5. FAQ

1. Color of Card

PE (polyester) Coating

PE (polyester) coating: Using high molecular polymer as monomer and addition of alkyd, this PE coating method of our color coated aluminum coil is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure makes paint surface luster and smooth, which assures good printing on the PE coated aluminum coils surface. With a warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

2. Color Match

For custom' color requests, we can deal as following:

a. Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

b. New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days.

c. Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it is suggested all panels are placed in one order for same project. And keep same direction as arrow on protective film when installing to avoid any color difference by vision

3. How long can we receive the product after purchase?

15-20days for general specification and 35days for special specification after receiving the deposit.

- Q: How to pull the aluminum coil purchased into aluminum sheet?

- You can buy flat sheet directly next time to avoid trouble.

- Q: What are the common alloys used in aluminum coil production?

- The common alloys used in aluminum coil production are 3003, 3105, 5052, and 6061.

- Q: This question asks for a comparison between cold rolling and hot rolling processes, specifically in the context of steel wire production for coilings.

- <p>Cold rolling and hot rolling are two distinct processes used in the manufacturing of steel wires for coilings. Hot rolling is performed at high temperatures, typically above the recrystallization temperature of the steel, which allows the material to be shaped more easily. This process results in a more ductile and less hard steel, which can be beneficial for certain applications. However, hot-rolled steel may have a rougher surface and may require further processing to achieve desired dimensions and surface finish. Cold rolling, on the other hand, is done at room temperature, which imparts a harder and smoother surface to the steel. It is more precise and results in tighter tolerances, making it suitable for applications requiring high strength and precision. Cold-rolled steel also has better surface finish and dimensional accuracy compared to hot-rolled steel. However, cold rolling is more energy-intensive and may not be suitable for very thick materials due to the increased hardness of the steel at room temperature.</p>

- Q: This question asks for a comparison of various types of equipment used for welding aluminum coils, highlighting their distinct features and applications.

- <p>Aluminum coil welding equipment varies based on technology, power source, and application. TIG (Tungsten Inert Gas) welders are known for high-quality welds and are ideal for thin aluminum coils. MIG (Metal Inert Gas) welders are versatile and suitable for thicker coils, offering faster welding speeds. Stick welders are more portable and cost-effective but produce lower quality welds. Laser welders provide precise, deep penetration welds suitable for high-precision applications. Friction stir welding is a solid-state process that offers excellent joint properties without melting the metal. Each type has its advantages and is chosen based on the specific requirements of the welding task, such as material thickness, weld quality, and production rate.</p>

- Q: How do aluminum coils contribute to sustainable building practices?

- Several ways exist in which aluminum coils contribute to sustainable building practices. To begin with, aluminum, being a highly recyclable material, has a minimal impact on the environment in terms of production and usage of aluminum coils. The process of recycling aluminum requires significantly less energy compared to the production of new aluminum, thereby reducing greenhouse gas emissions and conserving natural resources. Furthermore, aluminum coils possess the qualities of being lightweight and durable, making them an excellent choice for sustainable building practices. The lightweight nature of aluminum reduces the burden on the building structure, resulting in lower transportation costs and energy consumption during construction. Moreover, the durability of aluminum coils ensures a long lifespan, reducing the need for frequent replacements and the generation of associated waste. Additionally, aluminum's resistance to corrosion and minimal maintenance requirements contribute to the longevity of buildings, thereby reducing the need for repairs and replacements over time. This not only saves resources but also diminishes the overall environmental impact of the building. Moreover, aluminum coils exhibit excellent thermal conductivity, which can enhance energy efficiency in buildings. When incorporated into insulation systems or HVAC systems, aluminum coils assist in temperature regulation and minimize energy consumption. Consequently, this can lead to reduced energy bills and a smaller carbon footprint for the building. Lastly, aluminum coils find utility in various applications, including roofing, cladding, and ventilation systems. Their versatility allows for innovative and creative design solutions, supporting sustainable building practices by integrating energy-efficient features and promoting natural ventilation. In conclusion, aluminum coils contribute to sustainable building practices through their recyclability, lightweight and durable nature, resistance to corrosion, thermal conductivity, and versatility. By opting for aluminum coils in construction, we can reduce the environmental impact of buildings, conserve resources, and promote energy efficiency, ultimately fostering a more sustainable built environment.

- Q: How do aluminum coils contribute to sustainable manufacturing?

- Aluminum coils contribute to sustainable manufacturing by offering numerous environmental benefits. Firstly, aluminum is a highly recyclable material, meaning that the coils can be reused repeatedly without any degradation in quality. This reduces the need for virgin aluminum extraction, saving energy and resources. Additionally, the lightweight nature of aluminum coils reduces transportation costs and fuel consumption during shipping. Furthermore, aluminum is corrosion-resistant, leading to longer product lifespans and reducing the need for frequent replacements. Overall, the use of aluminum coils promotes sustainability through efficient resource utilization, reduced emissions, and increased product longevity.

- Q: Are aluminum coils suitable for food processing and packaging?

- Aluminum coils are indeed suitable for food processing and packaging, as aluminum is a highly versatile metal that offers numerous benefits to the food industry. Firstly, it possesses exceptional thermal conductivity, enabling efficient heat transfer during food processing and cooking. This characteristic guarantees even cooking and prevents the formation of hot spots or uneven heating. Moreover, aluminum proves to be an exceedingly corrosion-resistant material, a crucial aspect for food packaging. It effectively shields the food from external elements such as moisture, oxygen, and light, all of which can degrade the quality and freshness of the product. Aluminum coils can be effortlessly molded into various shapes and sizes, making them an ideal choice for packaging a wide range of food products, including cans, pouches, trays, and lids. In addition to these advantages, aluminum is a lightweight material that facilitates convenient transportation and reduces energy consumption during distribution. Its recyclability feature further contributes to minimizing the environmental impact of food packaging. In summary, aluminum coils are exceptionally well-suited for food processing and packaging due to their exceptional thermal conductivity, corrosion resistance, versatility, lightweight nature, and recyclability.

- Q: What are the different coil annealing options available for aluminum coils?

- There are several coil annealing options available for aluminum coils, depending on the desired outcome and requirements. 1. Full Annealing: This is a process where the aluminum coil is heated to a specific temperature and then slowly cooled down. Full annealing helps to relieve internal stresses, improve ductility, and enhance the mechanical properties of the coil. It also results in a soft and fully recrystallized structure. 2. Solution Annealing: Solution annealing is primarily used for heat-treatable aluminum alloys. It involves heating the coil to a temperature above the alloy's solvus temperature, followed by rapid cooling. This process helps dissolve and redistribute any alloying elements, resulting in a homogenous microstructure. 3. Stabilization Annealing: Stabilization annealing is performed on certain aluminum alloys to enhance their dimensional stability and reduce the risk of distortion during subsequent processing or usage. It involves heating the coil to a temperature just below the alloy's recrystallization temperature and then slowly cooling it. 4. Stress Relief Annealing: This type of annealing is performed to relieve residual stresses that may have developed during previous manufacturing processes, such as rolling or stretching. The coil is heated to a specific temperature and held there for a certain duration, allowing the stresses to relax. It helps to improve the coil's formability and minimize the risk of deformation during subsequent operations. 5. Intermediate Annealing: Intermediate annealing is performed during the manufacturing process to restore the ductility and formability of the aluminum coil. It involves heating the coil to a temperature below the recrystallization temperature, followed by a controlled cooling process. This helps to eliminate work hardening that may have occurred during previous operations. These are some of the common coil annealing options available for aluminum coils. The specific choice depends on factors such as the alloy composition, intended application, and desired material properties. It is important to consult with experts or heat treatment professionals to determine the most suitable annealing method for a particular aluminum coil.

- Q: Is it possible to use aluminum coils in the construction of a solar charger or battery pack?

- <p>While aluminum coils can be used in various electrical applications due to their conductivity, they are not typically used in solar chargers or battery packs. Solar chargers and battery packs usually require materials with higher conductivity and specific properties for efficient energy transfer and storage. Copper is more commonly used for wiring in these devices due to its superior conductivity compared to aluminum. Aluminum may not provide the necessary efficiency and could lead to energy loss. For the best performance in solar chargers and battery packs, it's recommended to use materials specifically designed for these applications, such as high-quality copper wiring and appropriate battery cells.</p>

- Q: I have heard that aluminum may be a contributing agent in causing Alzheimer's disease, and that if we drink from aluminum cans, that we get aluminum into our system from them. It seems like this would be pretty easy to test in a laboratory, whether or not there are aluminum particles in the contained beverage. But I have heard or read that the inside of the cans are coated with something. So is this just typical uninformed rumors from the Internets, or is there anything to it? Hate to sound rude, but I am not really interested in opinions, like Well I don't think they would sell them if... or Oh yes, I think you get lots of aluminum from it. I am only interested in facts, not gut feelings or opinions.

- As mentioned, there is a coating on the inside of the can that prevents the drink from coming into contact with the can. You won't be getting any aluminum, HOWEVER in that coating is a chemical called BPA. This chemical has been shown to affect the body's hormonal systems and can affect the birth of future children, even if one is not presently pregnant. It has recently been declared a toxic substance in Canada and other countries seem to be slowly following suit in declaring it as such. This chemical is used because it is cheap. Governments tend to be very hesitant banning things that are harmful if they affect the way corporations can make money. I try to avoid cans for this very reason. When you drink from them you'll be getting trace amounts of this chemical. Trace amounts over time add up in the body, especially with this chemical.

Send your message to us

High Quality 6063 Aluminum Coil Manufacture for Coated Aluminium Coils for ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords