CNBM Raw material System for Tons of Potassium Sulfate (SOP) Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tons of Potassium Sulfate Project

General

CNBM is a high-tech enterprises international chemical engineering company, who is pioneering in chemical engineering technologies, and playing a leading role in new technology development, with capability of project consulting, design, procurement, construction management and production guidance. CNBM provide services of chemical engineering and technology, with offering a scope of supply ranging from process design till the supply of completely integrated plants. CNBM master a technology of Potassium Sulfate production line, Calcium Chloride production line,sulfuric acid production line other fertilizers.We have cooperated with many international companies on projects,located Indonesia,Philippines,India,Jordan,Egypt.etc.

Process Description

It is well-known as there are two kind of popular methods to be used to produce Potassium Sulphate Product, one is Double decomposition method, the reaction is not good, the product quality should be improved. Another method is the Mannheim furnace process, it is used widely. But there are some difficulties occurred during the production. CNBM had made the necessary and important improvement and perfection on its production equipment and production process of Mannheim furnace, to form a unique and perfect Potassium Sulphate production technology now. Our improved process had been successfully applied in Philippines, Indonesia and Egypt, to be approved that our process and technology is excellent, gets the Customer’s credit, trust and satisfaction. Of course, CNBM has been dedicating himself into building the best quality Potassium Sulphate Plant, to produce best quality final product.

The production process is showed as below:

Using KCl (MOP, Potassium Chloride) reacts with Sulfuric Acid to produce K2SO4 (SOP, Potassium Sulphate) and HCl (Hydrochloric Acid) as a by-product, the reaction formula is showed as below::

2 KCl + H2SO4 → K2SO4 + 2 HCl

The reaction of Sulfuric Acid with Potassium Chloride takes places in two stages:

a. KCl + H2SO4 → KHSO4 + HCl

b. KCl + KHSO4 → K2SO4 + HCl

The first reaction step is exothermic and proceeds at relatively low temperature. The second is endothermic and must be carried out at higher temperature. To minimize the Chloride content of the product, a small excess of Sulfuric Acid is used, which is later neutralized with Calcium Carbonate, depending on the purity requirements for the product.

The reaction is usually carried out in furnace which special designed by our company.

The furnace has a closed dish-shaped chamber, with diameter up to 6 m, heated externally by oil or gas burner. Potassium Chloride and Sulfuric Acid are fed into the chamber in the required ratio at an overhead central point. The mixture reacts with evolution of heat and it’s mixed by a slowly moving agitator fitted with central axle, the reacted material is ejected to next equipment from both side of furnace. Potassium Sulfate leaves the reaction chamber at this point and be neutralized and cooled. Hydrogen Chloride gas formed is absorbed in water to form Hydrochloric Acid.

Structure and principle

The Mannheim furnace is made of high temperature resistant refractory bricks, thermal insulation bricks and ordinary red bricks. The top of the furnace is insulated with insulating bricks and asbestos. The reaction furnace has two cavities, and the middle elliptical cavity is a reaction chamber. Sulfuric acid and potassium chloride are uniformly added into the reaction chamber of the Mannheim furnace through a feeder. The cavity of the reaction chamber is a combustion chamber, and the combustion chamber has a burner. The heat released by the fuel indirectly heats the reaction chamber. The chamber is equipped with a stirring tweezers. When the reaction is carried out, the tweezers are rotated at 1 to 2 r /min, and the sulfuric acid and potassium chloride are continuously mixed to form potassium sulfate and hydrogen chloride gas. The potassium sulfate is pushed out by stirring the stirring tweezers, and the hydrogen chloride gas is recycled.

Sulfuric acid and potassium chloride are uniformly added to the Mannheim furnace reaction chamber through the feeder, and the combustion chamber provides a large amount of heat energy for the materials reacted in the reaction chamber. Under the stirring of the stirrer, the reactant sulfuric acid and potassium chloride absorb a large amount. After the heat is produced the product potassium sulfate with HCl gas. Potassium sulphate is introduced when stirred by a blender.

Characteristics

The diameter of the furnace directly determines the production capacity. Generally, the production capacity of Mannheim furnace is measured by the daily production capacity of a single reactor. Due to manufacturing technology and materials, the world's largest Mannheim furnace is 6 m in diameter.

The tweezers drive system is stable and reliable, thus providing a guarantee for continuous and stable reaction.

High material requirements. The refractory material used in the furnace reaction chamber must be resistant to high temperature, strong acid and heat transfer; the combustion chamber material must be resistant to high temperature and good heat preservation performance; the material of the scorpion must be heat-resistant, corrosion-resistant and wear-resistant; Whether the material meets the requirements directly affects the inspection period and the service life of the furnace.

There are temperature control and safety protection systems.

Oven method

After the completion of the Mannheim furnace, the natural drying is first carried out, all the inlet doors, the feed opening and the discharge opening are opened for natural ventilation, and the ventilation can be temporarily ventilated by the fan. After 7 days of natural drying, the burner is ignited. Switch to an open flame. When the open flame is baked, the flow of dry gas and air should be adjusted, the fire should be strictly controlled, the temperature of the furnace should not be too fast, and the temperature should be constant temperature after reaching a certain temperature.

Purpose of the original oven

Mannheim furnace is made of refractory materials, heat-insulating materials and other materials. It contains a lot of water. The oven is to evaporate its water to achieve drying and drying, so that the thermal expansion and displacement of all parts of the masonry are fixed. The hardened material is hardened to prevent cracking and spalling due to evaporation of water and transformation of the crystal structure of the material when subjected to rapid heating or cooling, and the oven and the production are to be continuously performed; if it is not immediately put into operation, it is baked after the reactor is completed. To ensure that the entire masonry is dry to protect the furnace body.

Problems and solutions

The stove is too hot. The uneven heating of the two heating chambers caused the partial furnace phenomenon, and the temperature unevenness caused the reaction to be unbalanced. As a result, the product quality was unqualified; due to the uneven heating of the furnace body, the material expansion was inconsistent and the furnace body was damaged. The solution to the problem is to adjust the burner gas addition amount and air volume.

The bottom of the furnace leaks acid. After a period of operation, the reaction furnace has a high reaction temperature, strong corrosiveness of sulfuric acid, and masonry, causing leakage of sulfuric acid at the bottom of the furnace. Treatment method: stop material, extinguish fire, cool down, remove the material in the furnace, find the leak point, if it can be repaired, block it with water glass and acid-resistant glue; if there are more leaks and larger area, it needs to clean the bed brick comprehensively. Check the bed base. If there is no problem with the bed base, rebuild the hearth brick. If there is any problem, you need to clear the bottom of the furnace and rebuild it.

The top of the furnace is leaking. Strong temperature makes the roof break. There are two remedies: the loophole is small, covered with refractory high temperature felt; the hole is large and rebuilt.

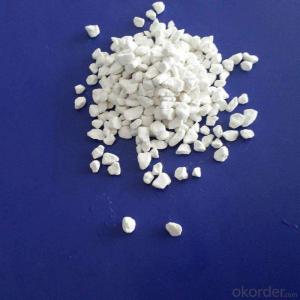

Pictures

- Q: I'm planning on getting a machine for $65000, I've never had any loans or buy a new car. My credit scores are not good in 2 bureus are 670 and Expirian is 570. I'm trying right now to improve my credit scores but it's not easy, takes time. I applyed in City Financial for a personal lon (not that I need one) but just to try to get the loan and pay it off. But I was denied. So I decided to use more of my credit card so it will show in my cradit report that I had a bigger loan ($7000). And then pay off the credit cards. If you have any ideas what shoul I do I'll appreciate you answer. Thank you in advance.

- It will be very hard to get a loan for 65,000 with little credit history. What will make it even harder is if you can't show income. The manufacturer of the equipment may have finance available through them, since if you default, they can take back possession. Most banks will consider a piece of machinery a poor securitization option because there is such a limited market.

- Q: what are association for computing machinery?

- ACM okorder /

- Q: I wanted to be a petroleum engineer due to its high salary, but am unsure if it's worth it.Is it worth it? Is it fun?Aeronautical engineering doesn't have a salary as high, but it seems like a fun job.I am hard of hearing and wear hearing aids. I suppose both jobs would accept this type of person.Which of those jobs has a better hiring rate?

- Petroleum engineers do not have any thing to do with the design of machinery. Their primary interest is the underground reservoirs that contain oil and gas. They can spend some time around a drilling rig but they do most of their work in an office. Having hearing aids should not be a problem in terms of employment. You need to realize that picking discipline for salary is the wrong thing to do for two reasons. One you should always work at something you enjoy and are good at. Two, just because a given discipline has a higher average salary doesn't mean you will be one of the engineers that earns that higher salary.

- Q: I am involved in assessing equipment for a vehicle refurbishment workshop like lathe ,milling machine, crankshaft re grinder and so on.How old should these machines be to be considered obsolete(years)?Thanks

- Something is only obsolete when you no longer have a use for it. As long as everything is in safe, working order and performs a useful function, it is not obselete. For woodworking, I still use large wooden clamps with wooden screws. They've gotta be like 30 years old, but they do exactly what I need them to do. If I got a strong, metal clamp, then the wooden one would be obsolete. Only replace what you need to replace.

- Q: Imagine building a cruise boat with no modern machinery. You'd have to cut down 10,000 trees. Cut them into lumber. tie or glue a boat together, build cages, store food and water, feed every animal, clean up animal waste, steer the boat, and sleep all while the biggest storm in the world sinks the planet. Can you really think that?

- Well actually it's pretty possible to build a boat without modern machinery. It certainly takes very long, but with nails, tar, and rope you can go quite a long way. And now I'm going to use the Metaphor Card: It didn't literally mean all the animals, and many parts are embellished, or even made up. The Bible was written by mortal men, after all. And I'm not even Christian.

- Q: About rubber machines, such as Intensive mixer, kneader, pelletizer, extruder, mixing mill...etc.

- Call one or look in the yellow pages.

- Q: which industries use industrial robots, and which use industrial machinery?

- Every okorder /

- Q: What's the difference between rap music and the din of a machinery shop?

- Real Rap is Poetry about the hardships of everyday life and it's injustices with a music background. The din of a machinery shop is the clanging and whirring of machines.

- Q: can bacteriophages use the human DNA machinery for replication?

- No, humans are eukaryotic (with different enzymes for replication) whereas bacteriophages, which attack bacteria need prokaryotic replication machinery for successful completion of life cycle.

- Q: I would like an example workout routine thank you! :)

- Here's a basic workout routine. 5 sets of 20 pushups 5 sets of 10 triangle pushups. 1 minute plank 3 times. 5 sets of 20 crunches 5 sets of 20 leg lifts 5 sets of 20 V-crunches 5 sets of 20 bicycle crunches. 5 sets of 15 jumping squats. Take a 30 second break in between each set and a 1 minute in between each exercise. If you're unfamiliar with any of these exercises just google them. If this seems a bit too intense for you, you can modify it as you please and then work up to the suggested workout. It's better if you do this every other day since it is quite intense. Remember to do 10 minutes of stretching before and after the workout. Do cardio the next day. I got results with this in the first 2 weeks, and got amazing results within 2 months. Just remember to have a healthy diet and stick to the workout routine too. Luck.

Send your message to us

CNBM Raw material System for Tons of Potassium Sulfate (SOP) Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords