CNBM Tons Potassium Sulfate (SOP) Project equipments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tons of Potassium Sulfate Project

General

CNBM is a high-tech enterprises international chemical engineering company, who is pioneering in chemical engineering technologies, and playing a leading role in new technology development, with capability of project consulting, design,procurement, construction management and production guidance. CNBM provide services of chemical engineering and technology, with offering a scope of supply ranging from process design till the supply of completely integrated plants. CNBM master a technology of Potassium Sulfate production line, Calcium Chloride production line,sulfuric acid production line other fertilizers.We have cooperated with many international companies on projects,located Indonesia,Philippines,India,Jordan,Egypt.etc.

Potassium sulfate product quality standard

Potassium sulfate | index | standard | |

| K2O:% | ≥50 | GB20406--2006 | |

| CL-:% | ≤1.0 | ||

| H2SO4:% | ≤0.5 | ||

| H2O:% | ≤1.0 | ||

Mannheim method potassium sulfate production process:

(1) It is a production process with little environmental pollution ;

(2) Mature technology, easy to industrialize production, improved new technologies and new processes, adapt to the requirements of the market economy, enhance the competitiveness of products in the market, the quality of potassium sulfate is good, and the output is high;

Main raw and auxiliary materials supply

| NO | Name | specification | Consumption | Total annual consumption |

| 1 | Potassium chloride | K20≥60% | 830Kg/t | 83,000 tons |

| 2 | sulfuric acid | 98% | 570Kg/t | 57,000 tons |

| 3 | lime | 40Kg/t | 400t |

Introduction to the preparation of potassium sulfate production plant by Mannheim method

Raw material for producing potassium sulfate

The raw material for the preparation of potassium sulfate by the Mannheim method is potassium chloride (KCL) which has K2O ≥ 60% and 98% sulfuric acid.In the production process, the hydrochloric acid system is made into tap water, and the heat required for the reaction is provided by natural gas combustion.

The nature and use of potassium sulfate

K2SO4

Colorless or white crystal or powder, bitter and salty

Melting point: 1069 ° C, soluble in water, insoluble in ethanol, acetone and carbon disulfide, the aqueous solution is slightly acidic.

Uses: 1. Agricultural fertilizer, used in tobacco, fruit trees, sugar cane, potatoes, vegetables, etc.

2, used as a drug (a laxative) and used in the manufacture of alum, glass and potassium carbonate.

Potassium sulfate quality specifications

Appearance: colorless or white crystal or powder.

Industrial synthetic hydrochloric acid

Relative molecular weight: 36.45

Performance: colorless transparent liquid, yellow when there is a small amount of impurities, strong acid is corrosive, can work with a variety of metals.

Uses: Important chemical raw materials for petroleum, metallurgy, printing and dyeing industries, etc.

Basic principle and process flow of potassium sulfate production

A fixed bed metathesis reaction method is employed. The solid potassium chloride and 98% sulfuric acid are continuously added to the reaction chamber at a certain ratio of feed, and the reaction is carried out under the condition of pushing the homogenate at a high temperature above 500 ° C (generally controlled at 500-530 ° C). . The raw material is continuously input under the condition of maintaining the normal bed surface, and the finished potassium sulfate is continuously discharged into the finished pusher from the outlet of the reaction chamber (symmetric two places), and enters the finished product through the gas seal conveyor under the action of cooling and stirring and pulverizing. The belt machine is then lifted, crushed, and finished with a scraper into the finished silo. The hydrogen chloride gas generated in the reaction is absorbed into water to prepare a hydrochloric acid and charged into a storage tank. Exhaust gas is discharged into the atmosphere in accordance with national emission standards.

H2SO4+2KCL →K2 SO4+2HCL-Q

H2SO4 → SO3+H2O-Q

HCL+H2O → HCL·H2O(HCl)+Q

SO3+H2O → H2SO4+Q

Production equipment overview

Potassium sulfate reactor

The reaction furnace is mainly composed of a combustion chamber (upper) reaction chamber (middle) flue chamber (lower part), and is equipped with a feeding and mechanical stirring pushing device. The core device of the Mannheim method is the reaction furnace. The purity of the product, the conversion rate, the production capacity and the difficulty of operation are all related to the reaction furnace. Therefore, reactor performance is the key to the process. The reaction furnace is mainly made up of a variety of special refractory materials. It has two cavities. The middle elliptical cavity is the reaction chamber. The chamber is equipped with stirring tweezers. When the reaction, the tweezers rotate at 1.1r/min, and the materials are continuously mixed and gradually. Push around the cavity. The upper cavity of the reaction furnace is a combustion chamber, and the combustion chamber has a burner, and the heat released by the fuel indirectly heats the reaction chamber.

Overview of the auxiliary equipment of the reactor system

1. The main machine (with large reducer and motor driven spindle) provides the effect of fabric, mixing and product removal.

2.Reheater: φ1000×4600, cold air and flue gas heat exchange, to preheat the air, reduce the heat loss in the furnace.

3.Potassium sulphate finished product pusher: The pusher barrel is accompanied by a cooling jacket, which functions as cooling, crushing and transfer of the finished product (n≈5.53r/min).

4.Gas-sealed screw conveyor: the function of finished product conveying and gas sealing.

5.Finished belt conveyor: The finished product is conveyed with cooling (with magnets - prevent the iron from entering the rear equipment).

6.Finished bucket elevator: finished product delivery.

7.Finished squeegee conveyor: The finished product is conveyed with cooling jacket.

8.Dust collection bucket, dust collection fan, distributor: collect the finished dust back to the silo.

9. Carbon cooler: After the hydrogen chloride gas at the outlet of the reaction chamber is cooled by the heat exchange, the temperature is lowered to about 50 ° C, and sent to a sulfuric acid gas scrubber.

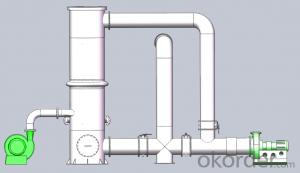

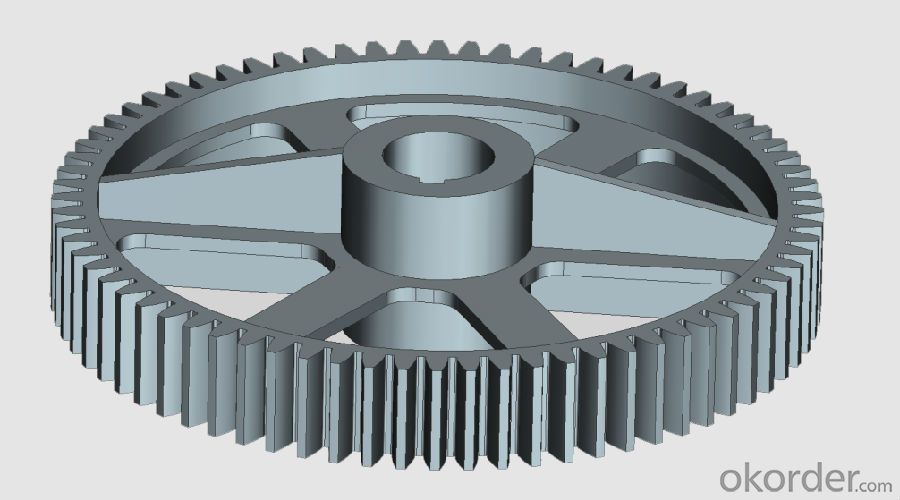

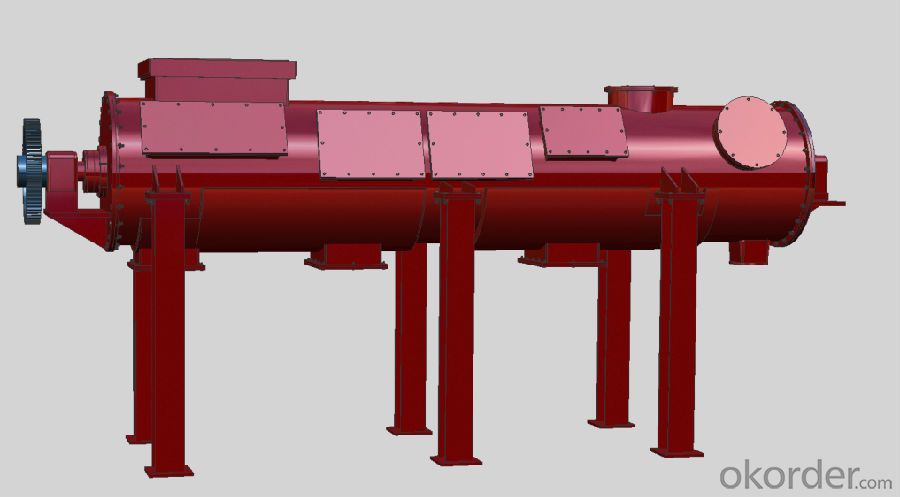

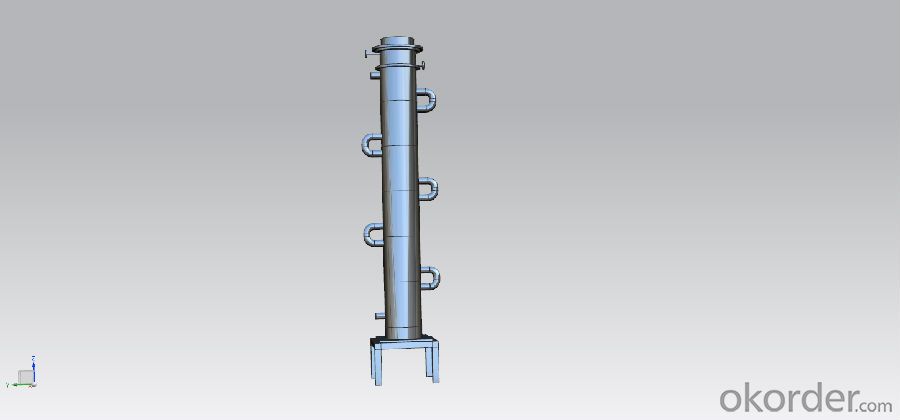

Images

Big gear

cooling pusher

cooling pusher

Graphite cooler

Graphite cooler

- Q: I am related to building and construction business. I want to buy new and second hand building and construction machinery like cairns and excavators. Can you tell me any good web site where I can check the prices and specifications of these machineries and buy them?

- If you purchase new equipment the new equipment will come with a warranty.You would have to take an expert mechanic with you when you look at used equipment.You would also have to know your district's laws.Some crane types might be illegal in your district.If someone tries to sell you an illegal machine you would have to take the appropriate legal measures.

- Q: I have an assignement where I have to explain how ribosomes in plant cells are equivalent to a machinery in a city.I understand the concept and the general idea, but I don't know how to word it out and explain it clearly.Any ideas?Thanks!

- ribos keep the body moving and working, just like machinery in a city. it takes the garbage truck picking up the trash, delivery trucks bringing in fresh produce, police cars keeping the peace, construction machinery building new structures and so on so the city continues to function as a whole. when one piece of machinery breaks down it causes a chain reaction that affects thru out the city. same goes for your mind and body. good luck

- Q: What is mechanical engineering?

- Introduction to mechanical engineering related science and technology as the theoretical basis, combining the technical experience in the production practice, study and solve in the application of discipline development, design, manufacture, installation, use and repair all kinds of machinery in all theoretical and practical problems. Machinery is one of the five essential elements of production and service in modern society (human, capital, energy, material and machinery), and is involved in the production of energy and materials.

- Q: Has anyone else ever noticed how much more timid women are with working around noisy power equipment, guns, and machinery than men are? Do they feel overpowered by this stuff or something? Note: This doesn't apply to all women, as I do know of several women that aren't afraid of these things. Although, most of those I've talked with told me that they were afraid at first and then they got used to it over time.

- I think because women are less physically strong, we're scared, yeah. I'm over it, have used tons of power tools, my Daddy's awesome with tools/building so we've spent a bunch of time together doing things he enjoys, which meant I learned to use power tools. Turns men on when women use power tools, I wonder why that is? Even my Daddy loves when my Mamma uses a saw or something haha Yet, he gets pretty angry when we're out int he summer and people walk by the house and stare while I'm working haha =o) The table saw, I still have never once used that, he warned me it could possibly snap my wrist...that was enough to keep me away from it! o_O

- Q: what are association for computing machinery?

- It is the professional organization for computer programmers and such. Yeah, they know about the jokes about 'association for machinery.' But its been around a long time.

- Q: What are the total cost of the project?

- (3) other expenses for the construction of the project, including land fees and other expenses related to the project, that is, the relevant government fees and other expenses related to the future production and operation, that is, the cost of their own operation. (4) preparation fee (including basic reserve fee and price increase reserve fee, that is, risk reservation allowance), (5) loan interest during construction period, this is relatively clear.

- Q: car, machinery diagnostic type person.

- right!!!!!!!

- Q: And what does taking flu medicine have to do with perfoming operations?

- sure, fat people need surgery too!!

- Q: Senator Barack Obama has grown from not known at all to well known in a relatively short time frame. He has come up on the rough side of the mountain to claim the front runner status. He has a wildcard of a chance to beat out two well known candidates. Senator Clinton and John McCain.Amazing journey.

- Agreed...I have been an Obama supporter since day one, but even I could not have envisioned this. I figured that i would end up having to vote for Hillary in November..I am pleasantly surprised that so many people have joined me in taking a chance at having something better

- Q: Do you know how to operate any machinery?

- Yes, most Engineering Machinery :)

Send your message to us

CNBM Tons Potassium Sulfate (SOP) Project equipments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords