CNBM Tons of Potassium Sulfate(SOP) Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tons of Potassium Sulfate Project

Overall introduction:

Production of potash sulfate project, is my company a new technology of the success of scientific research personnel development research. Is the core of this technology in Germany dry roasting, on the basis of production of potassium sulfate, improved the structure of mannheim furnace and become a new type of reactor, combined with other specialized equipment, it has successfully solved the high temperature, strong acid problem of corrosion resistant materials, as well as the continuous production technology of feeding problems. Compared with similar foreign equipment, its outstanding characteristic is less investment, short build period (4 ~ 6 months), a high degree of automation, stable operation, high thermal efficiency, strong operability, high product yield, quality and reliable, good environmental protection effect. From engineering design, equipment manufacture, installation and production technology, product testing, complete sets of technology and equipment, all have the company independently to complete, and has set up a successful for home and abroad (Indonesia, the Philippines, India, Egypt, etc.) vendors are many sets of equipment and technology transfer, has achieved good effect.

The preparation of potassium sulfate and hydrogen chloride gas generated in the reaction chamber. Its formation reaction process is as follows: indoor temperature control within the range of 510-560 ℃, the equipment is in normal operation and standby condition, according to the dosing raio of appropriate by the metering device straight into potassium chloride, sulfuric acid in the reaction bed fully blend to generate potassium sulphate and hydrogen chloride gas reaction. Of hydrogen chloride gas hydrogen chloride by continuous smoke exhauster and maintain the reaction chamber is slightly negative pressure, the finished product potassium sulfate is continuously removed from the reaction chamber into the control cooling pusher, potassium sulfate by cooling and crushing, goes further, by the air seal screw conveyor sent to the belt conveyer, add a small amount of powder after screening, crushing and after the acid into the finished product bin, metering packaging sent to potassium sulphate finished-parts storage.

Hydrogen chloride gas cooling absorption: (1) the hydrogen chloride gas generated by the reaction chamber, outlet temperature as high as 400 degrees, the need to heat cooled to 50 ℃ or less to facilitate the preparation of sulfuric acid gas washing and hydrochloric acid, the process is carried out within the carbon cooler. Because of is contained within the hydrogen chloride gas dust sundry, to prevent carbon cooler jam, accompanied by mixed acid washing process, washing liquid from the pickling pump discharge, and hydrogen chloride gas flow back to the sulfuric acid gas scrubber, cooling water by the water distributor from bottom to top, back to back to a vase with secondary cooling.

Since the carbon in the discharge of hydrogen chloride gas cooler with a small amount of sulfuric acid gas (mainly sulphur trioxide) and material particles. For making high quality of hydrochloric acid to sulfur trioxide and particle washing net is necessary, the process conducted in sulfuric acid gas scrubber, mixed acid absorption liquid control certain concentration, remove is sent to the mixed acid of continuous, dilute hydrochloric acid sent by the exhaust gas recycling system, after washing the hydrogen chloride gas entering the acid system.

Hydrogen chloride gas after washing with dilute hydrochloric acid from hydrochloric acid absorber group B downstream into hydrochloric acid absorber group A complete falling film absorption process, concentrated hydrochloric acid to control concentration of hydrochloric acid tank in the middle. Not be absorbed hydrogen chloride gas into hydrochloric acid absorber of group B and add clean water upstream of the tower contact complete absorption process. Hydrogen chloride in tail gas recovery tower (1), high purity water by dilute acid tank, the metering device of continuous investment and control the right amount of water, absorbing liquid (dilute hydrochloric acid) A borrow into hydrochloric acid absorber in group A. Acid production process using four sets of parallel arrangement, due to the absorption of hydrogen chloride reaction is an exothermic process, the reaction heat must be removed before reaction of, so the hydrochloric acid absorber in group A with jacketed cooling device, cooling water from the water distributor, bottom-up to sink back into the pool, control group A tower outlet water temperature of 40 ℃ or less. Hydrochloric acid intermediate slot control a certain level, when in a timely manner after the predetermined level trough, sampling analysis of pump will be qualified with acid hydrochloric acid hydrochloric acid into the tank.

The exhauster to homemade hydrochloric acid system exhaust by recovery tower 1-2-3-4-5 into the chimney discharged into the atmosphere. Tail gas recovery system for the five towers in series process, hydrogen chloride gas with dilute hydrochloric acid inside the packing type recovery tower countercurrent contact reaction, hydrochloric acid concentration of exhaust gas by the no. 1 -... - > 5, gradually reduce, dilute salt concentration by 5 -... Gradually increase their form concentration gradient - > 1, 5 tower add clean water tower gradually transferred to the no. 1, no. 1 tower absorption liquid quantitative transfer to sulfuric acid gas scrubber, 1 tower also accompanied by sent to hydrochloric acid tank of liquid flow in the middle. Absorb as exothermic reaction, how many each tower temperature according to the absorption of hydrogen chloride by no. 1 -... - > 5 gradually reduce, also a temperature gradient. The absorption tower for micro positive pressure, exhaust gas to the chimney discharged into the atmosphere, and to ensure exhaust emission standard in order to run.

Potassium sulfate production process principle of the project, with sulfuric acid and potassium chloride as raw materials, reaction at high temperature, made a series of processing technology, production of main products of agricultural potassium sulfate and the by-products of industrial hydrochloric acid. By the technical supervision inspection, potassium sulfate reached GB20406-2006 product quality standard level, among them, the content of potassium hydroxide, chlorine ion content, moisture content and physical properties of various specifications are reaching or higher than similar foreign products. 31% byproduct hydrochloric acid can be adjusted according to the customer need the following products, various concentration of quality BG320-2006 standard requirements.

Potassium sulfate contains both crops necessary potassium ion, also contain sulfur in promoting role for the growth of crops, is a kind of potassium and sulfur compound fertilizer, used for all crops, particularly applicable to avoid chlorine crops, such as tobacco, tea, sugar beet, melon, potato, peanuts, beans, vegetables and so on, can not only increase crop yield, but also can improve the quality of crop products. For example, can raise the flammability of tobacco, the sweetness of grapes and watermelon, potato starch and so on, with chlorine, phosphorus is reasonable use of 10-25% of the increase production effect can be obtained. Because of lower potassium sulfate index, use for a long time without destroying the soil structure, it will also no longer cause soil acidity and salinization.

This project of by-product hydrochloric acid production, the quality meet or exceed the technical indicators of industrial synthesis of hydrochloric acid requirements, can be widely used in industrial boiler water electrolysis, electroplating, purification and chemical industry and so on equipment cleaning, also can be used for processing fields such as food, medicine, is one of the basic chemical raw materials, has a broad market prospect.

Economic and technical indexes:

①Technical index of agricultural potassium sulphate

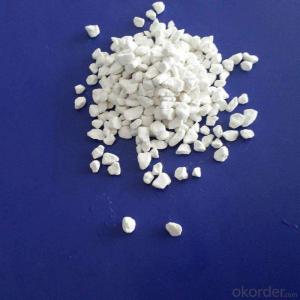

Appearance:colorless or white crystals or powders

②The technical index of the industrial hydrochloric acid

| The index item | index | ||

| Classy article | Grade A | Qualified products | |

| potassium oxide ≥% | 50 | 45 | 33 |

| chloride ion content ≤% | 1.5 | 2.5 | |

| Moisture content≤% | 1.0 | 3.0 | 5.0 |

| free acid by H2SO4 content ≤% | 0.5 | 3.0 | |

| Salinity(NaOH) content ≤% | 1.0 | ||

| The index item | index | ||

| Classy article | Grade A | Qualified products | |

| total acidity by HCL % ≥ | 30.0 | 30.0 | 30.0 |

| Arsenic(As) %≤ | 0.0001 | 0.0001 | 0.0001 |

| Residue on ignition %≤ | 0.08 | 0.10 | 0.15 |

| Chloride by CL- %≤ | 0.005 | 0.008 | 0.010 |

| Name | specificaiton | Rate of consumption | Remark |

| KCL | K2O≥60% | 850Kg/t | white powder. H2O ﹤1% |

| H2SO4 | 98% | 570Kg/t | |

| limestone powder | 60-100mesh | 40Kg/t | |

| electricity | 65KWh/t | ||

| Natural gas | 70 m³/t | ||

| Process / cooling water | 0.8M3/t/0.5M3/t | make-up fresh water 500Kg/t for closed circulation cooling system |

③Product consumption quota

④Main technical indicators

| The index name | Control indicators | remark |

| KCl | K2O≥60% H2O≤1% | White powder |

| H2SO4 | 98±0.5% | |

| K2SO4 | K2O≥50%, H2SO4≤1%, Cl≤1.5% | |

| Hydrochloric acid | HCL≥30% | Control Be°18-19 processing acid |

| Roof-temper | ≤980℃ | background of roof-combustion chamber |

| Furnace temperature | 510-560℃ | Reaction chamber |

| bottom temperature | ≤650℃ | tewel outlet |

Circulating water temperature/PH | ≤30℃/PH7-8 | |

| Drainage PH | PH6-9 | |

Graphite heat exchange gas outlet temperature | ≤50℃ | general control ≤50℃ In Summer ≤60℃ |

| liquid level in Tower | 1/2-2/3 | level indicator |

Liquidlevel in intermediate cell of hydrochloric acid | ≤high liquid limit | level indicator |

Liquid level of 98% H2SO4 elevated tank | high liquid limit | Stable level by H2SO4 reflux |

Liquid level of dilute acid elevated tank | high liquid limit | Stable level by water reflux |

| oil level of gearbox | 1/2-2/3 | By sight glass or dipstick |

Images of productions:

- Q: find the yearly depreciation of the machinery

- (40000-5000)/10= $3500

- Q: How long did Noah take to design and build his 3 phase electronic machinery to build the Ark?

- In no time. Because he did not use electronic machinery. So it took zero seconds

- Q: Okay, so I'm looking through my bio textbook (not ap) and I come across this graphic about the HIV virus. There's a strip of text that talks about how the virus replicates itself:HIV is equipped with the enzyme reverse transcriptase.........Using the cell's **gene translation machinery**, this DNA then directs the production of thousands of viruses.The thing inside the **s . What is it? Cells don't have machinery! Why does the book call it translation machinery?

- It's talking about the complement of proteins used to copy the DNA and produce new viruses that are hijacked by the virus. Proteins are like little machines. They're the molecules that do everything in the cell.

- Q: My boyfriend is looking into becoming a heavy equipment operator, ive been looking for informations but i cant quite find any!I wanted to know things like is it in high demand and if he would make ok money? We live in Canada but if you live in the states ide still love to hear from you! So here are a few of my questions:-Do they make good money?-Do you have to move alot?-Is it a steady job, like an everyday thing?-Is it easy to move up in a company? (and possibly make more money?)Dont think im in this just for the money because im not :P i just think its important to make sure that you can support a family before you actually get into doing a job!Thanks a lot guys!!

- what exactly will he want to do? technician or operator? what type of machine ? these fields aren't going anywhere and most of them are steady. pay can range from $30K - $40K depending where you live and your training level. as for moving up in the company.... no idea. it all depends if the company trains you or sends you out for more training. then yes, they will want to keep you longer if they are investing money in you and will give you raises to keep you happy.

- Q: How many types of casting machinery?

- You have sand casting, lost wax casting, injection casting, cuttlebone casting, vacuum casting, centrifugal casting, and others, and each of those involves several machines for specific purposes. So you need to get specific about your question.

- Q: Who builds expanded metal machinery?

- Why don't you try typing expanded metal machinery on yahoo.

- Q: Explain the balance in an Accumulated Depreciation Machinery account and what it represents. Are they funds to replace the machinery when it wears out? If not, what does it represent?

- Depreciation On Machinery

- Q: I'm vacationing in Hong Kong and would love to bring home Japanese snack machineries such as Taiyaki makers, Takoyaki makers, Dorayaki makers, etc. It would be so nice to know if Hong Kong has vendors for these products. Thanks a lot!

- Hi, there'e NO Japanese snack food machine in Hong Kong. This machines applies in Japan only. The reason the japanese has these machines is to reduce the crowd of puchasing food, save time, save manpower, for people who need to line up at the restaurant or a take out food. This is a smart way of doing doing business. It also save time for ordering your food. No cashier needed right? But who knows, someday most countries will follow this way. Thanks for asking. Arigato gozaimasu.

- Q: For my law and justice class, im defending a guy who took some medicine that was labeled Do not operate heavy machinery. One hour after taking the medicine, he drove to tacoma to pick up his daughter and got in a car accident. So, would a car be considered Heavy Machinery?

- That would need more research .Technically a vehicle could be considered a motorized vehicle and fall into a machinery label. It is bigger than let`s say a lawn tractor. the way the label reads may also include any motorized vehicle. You need a more accurate definition of heavy machinery. Personally , when on medication with those warnings , I also include the fact that a motorized vehicle is also included. You can do more harm in a car doing 40 mph than you can do on a dozer doing 3 mph if your reaction times are impaired due to medication

- Q: A 20kw,200V shunt generator is operated at rated load. if the driving engine is developing 30bhp (break horse power), determine the iron and friction losses.PLease use all the given data above..thanksAnswer is IFL=1039W.Thanks a lot.

- This is the answer I gave to 2 other askers of the same question. brake horse power of an engine is the actual amount of horse power an engine can put out. Using 745.5 watts as a horse power, the engine will supply the equivalent of 30 times 745.7 watts at 30 brake horse power. This is 22,371watts. The generator is supplying 20 Kw or 20,000 watts. The difference in the engine output and the generator output is 22,371 minus 20,000 or 2.371 watts. I don't see how the answer is 1039 watts, if my calculations are correct. Perhaps someone else will have the answer you seek. I may be missing something in your question

Send your message to us

CNBM Tons of Potassium Sulfate(SOP) Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords