Cmax Timber Beam Formwork with Good Quality in Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

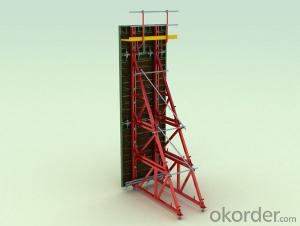

1. Structure of Timber Beam Wall Formwork Description

Timber beam wall formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost. The formwork is made of plywood, which is a coated special plywood using in the formwork systems where high requirements are set on the concrete surface and the times of reuses.Well treated to prevent from water penetration or erosion,so the service life maximally extented.Normally, CNBM timber beam H20 can be used for 4 to 5 years, the exact using time would

2. Main Features of Timber beam wall formworks

-Standardized production lines with supply capability :3000m/day, L=6600mm

-Robust caps at the end of the girders protect against damages

-In standard thickness, moisture content 10%

-Shearing force failure load: 40kg

-Lifespan:4~5 years

3. Timber beam wall formwork Images

4. Timber Beam Wall Formwork Specifications

-convenient for construction

-easy to control the quality

-easy, rapid and economical

5.FAQ of Timber Beam Wall Formwork

1) What can we do for you?

.We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can design the artwork for you.

. Please feel free to customize.

2) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

3) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

4) What promises can be done by us?

. If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us

- Q: This is the following plate, do not want to use PVC or aluminum edge, too ugly, there is no paint or putty kind of things, can maintain wood color better?Ash integrated plate edge treatment, do not scratch putty directly do varnish okay?

- Mongolian pine Oh, Hei hei do not need to deal with it

- Q: Furniture edge banding machine generally how much?

- What kind do you want, fully automatic, and semi automatic, imported and domestic? The price varies greatly.

- Q: Why does my kitchen cabinet door edge strip fall off, and the base board is particle board?

- What you call a particle board is what we usually call a shaving board. Generally, the edge of the shaving board is made of PVC sealing strip, and the main function is beautiful, and the moisture and moisture inside the board are contacted and damp, and the chemical gas overflow of the sheet can also be prevented. Edge off the following main reasons: 1. environmental problems caused by high temperature and high humidity; 2. furniture manufacturing when edge glue coating is not uniform; the 3. furniture manufacturing when edge strength is not enough, not pressed; 4. edge gum gum quality, too thin, too little or not uniform, resulting in 5. edge glue quality degumming; no, cause degumming; 6. furniture manufacturing, sealing machine temperature regulation, lead edge glue melting is not ideal. Generally determine the reasons, the edge of the strip will be removed from the back to observe, for your reference, hope to adopt.

- Q: What's the adhesive tape for the desk edge? What glue do you use?

- Structural adhesive, carpentry glue

- Q: The best window tile the edge? Answer urgently. Thank you

- I looked at the front of the reply, feeling is the choice of marble is better, you can choose black Jinsha, white jazz, beige marble series, although it is said that the marble radiation, why grade decoration will choose it, but not the wall ground in large area this does not matter, the threshold sill board is best choice of natural stone stone, artificial stone appearance was flattered, no more than the hardness of artificial stone, natural stone, with long scratches easily into the dust, not for a long time to, if it is because of the natural stone is not long enough for two pieces of good, on the not so obvious, the two pieces or three pieces can be, the most important the future is on the table cloth mat can be customized, the seam is even less to

- Q: What kind of material is good for plate type furniture edge banding?

- The edge is PVC, a special edge, you can see the picture in the online search, a reel of what colors are what color are mostly imitation wood, stainless steel and Aluminum Alloy there, but the metal edge is not high.

- Q: What are the reasons for the breakage of plastic bags? What is the reason that the material is BOPPCPP and the heat sealing edge is damaged?

- First, the heat seal knife too ruthless, too high temperature, burned CPPSecond, CPP tensile rate is not enough, so that in the event of external shocks, can not play an effective buffer effect.Third, BOPP and CPP structure itself can not contain many things, you pack too much, BOPP/CPP mechanical strength itself can not afford.Fourth, also need to see BOPP and CPP film thickness, because they are all polypropylene film, but the tensile strength is not the same, there will be problems.

- Q: To understand the people say that the "very east" brand automatic edge banding machine market prices, thank you!

- The extreme edge banding machine is the ancestor of Chinese edge banding machine. China made banding machine manufacturers, that does not follow the level of the East run. Yes, I have a whole new one here. I'm from Wenzhou, I don't know where you are. It's Zhejiang. You can choose me here. It's out of town. No, it's really necessary.

- Q: What oil is added in the motor of the automatic edge sealing machine? How often do you add a motor with a belt? Is there a small hole on it?

- Oil with high viscosity can be substituted.

- Q: Full automatic edge banding machine, what price, thank you

- See how you locate more expensive automatic edge sealing machine about 1000000.A good edge sealing machine can not be less high-quality edge banding; furniture edge banding, PVC edge banding, acrylic edge banding, ABS edge banding; Shanghai plastic decorative materials Co., Ltd.

Send your message to us

Cmax Timber Beam Formwork with Good Quality in Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches