Automatic Linear Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Automatic Linear Edge Banding Machine

1. Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2. Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3. It adopt the imported original electrical machinery, each performance is better.

4. It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5. Blow up and down the side, surface polishing up and down and so on.

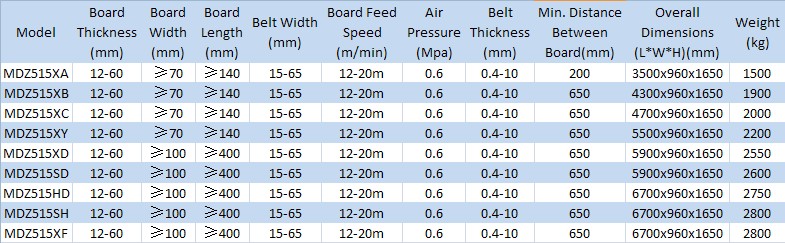

Specification of Automatic Linear Edge Banding Machine

Advantages of Automatic Linear Edge Banding Machine

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

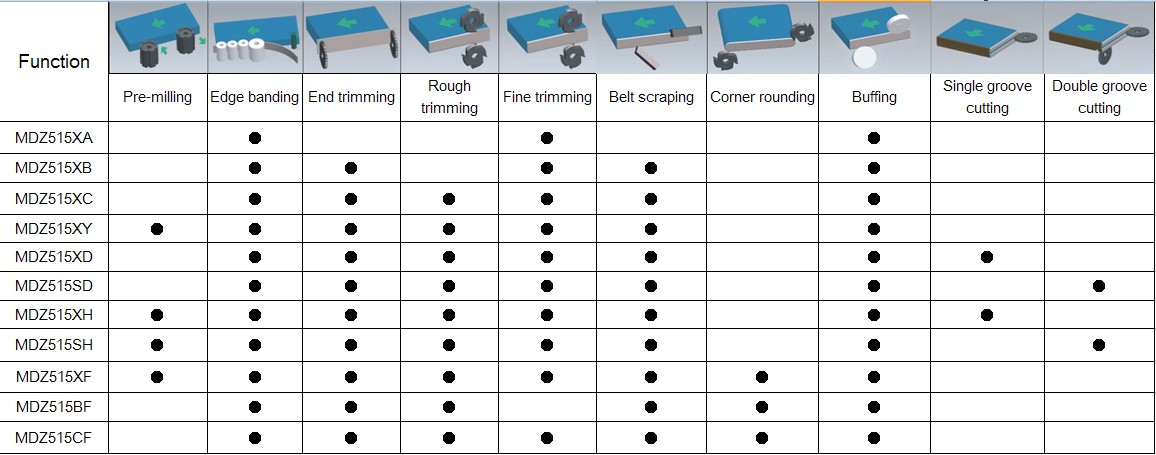

Main Functions of Automatic Linear Edge Banding Machine

Packing of Automatic Linear Edge Banding Machine

- Q: Teach you, the cabinet backplane thickness is generally 3mm or 5mm, please ask the backplane is also edge it? Prior to the introduction, each board has to edge, but this board is so thin, businesses will also seal the four sides? Or is it just a cover?

- When you say the use of 3MM or 5MM backplane, the body of the bracket is equipped with an installation slot, the back is inserted into the slot, without banding, there is no need.

- Q: The attic is covered with a multilayer board that needs cutting and the cut part needs to be coated with edge coating.What kind of paint is it with edge coating? Ordinary alkyd paint, okay? Or special carpentry paint?

- It's a kind of wood paint

- Q: How to seal the corner in the half corner of the wardrobe?

- Each of these companies is not the same, all can be sealed.

- Q: Huali woodworking machinery automatic sealing machine 105 do well?

- Machines can be, but good adjustment and stability of the machine

- Q: There are two favorite bags are all genuine leatherThe black tape with straps on the shoulder doesn't know how it fell offOne is OK, the other is a bit seriousIt's sticky. It's a little longer on the back of your bag. It'll stick to black sticky glue on your clothesCheck it online and there's no solutionTo the special leather cleaning, cleaning shop also asked them, do not know how to doThe majority of users want to help me,The serious one is hilly's toilet bagWould you like to ask a friend who bought this bag to come across this situation?

- The black glue melted. There are no special cleaning agents available for the time being.I suggest you change your shoulder straps.

- Q: Method for using small-sized edge banding machine

- 1. Turn on the power before checking whether the switch is in the closed position. Close the trimming and turn the heating switch on the right to make it work.2, the edge belt is arranged on the rotating disc edge is greater than the thickness of 3-4MM, otherwise edgeband can not completely seal plate, there will be a period of above or below the seams phenomenon, the edge by hand pressure with five-star lever into the scissors seat, front and rear belt pressing lever presses down edgeband not too tight, not too loose, too tight edgeband cannot pass through the pressure rod, loose edge will appear in front of or behind the phenomenon of deviation.3, before the start of the work to see if the melt has been melted, and then send the material size of the pressure modulation plate thickness, size, start the transfer switch, check the amount of sizing, and whether it is suitable for working conditions.

- Q: Can there be less or no addition of lead stabilizers in the PVC banding? Is there a replacement? Because China's ROHS on lead, chromium, mercury, cadmium content requirements.Is it possible to produce edge banding products that meet the requirements of ROHS? Around Beijing

- I am made of raw material; my material does not contain lead; the key is in the raw material

- Q: How do you close the wallpaper?

- The reason is that there is moisture in the air, the wallpaper will become warped when the time is long, and the building materials market has layering to solve the problem.If you want to say what a letter can be, the box can also, of course the best nail glue and nail, usually with a nail box, before in the frame with steel row nail plate and nail box using the nail, the nail is fine, is not obvious, the best way is to with the wood board nailed on the brace, and then paint on the panel, you can paint or free.

- Q: Custom made wardrobe in all friends custom made a wardrobe, a little worried about this edge, how to assess the effect of sheet metal banding?

- I think the whole friend's sealing edge is good

- Q: What oil is added in the motor of the automatic edge sealing machine? How often do you add a motor with a belt? Is there a small hole on it?

- Oil with high viscosity can be substituted.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Automatic Linear Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords