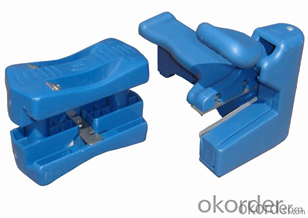

Portable Edge Bander KM600D Edge Banding Machines of Different Kinds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Edge Banding Machines-Panel Saw Description

A panel saw is any type of sawing machine with a sliding table that cuts sheets into sized parts.

A sliding panel saw was invented by Wilhelm Altendorf in 1906 in Germany. Its invention set a new standard in woodworking, with dramatic differences from traditional machines. Up to that time, a conventional table saw had no mechanism for edging. Meaning that for the first and second longitudinal cut on untreated massive wood, the lumber always had to be fed manually through the saw blade. The new system accomplished the task more elegantly by allowing the work piece to be fed through the saw blade while lying on a sliding table. Thus cutting becomes faster, accurate and effortless.

2.Main Features of Edge Banding Machines-Panel Saw

Panel saws are used by cabinet shops to easily cut panels, profiles, solid-wood, MDF, laminates, plastic sheets and sheets into sizes or cabinet components. They are also used by sign shops to cut sheets of aluminum, plastic and wood for their sign blanks. Some higher end panel saws feature computer controls that move the blade and fence systems to preset values. Other lower end machines offer simplicity and ease of use, including full scale hobbyist level panel saws at a mere fraction of the cost. While the entry level machines are designed for light duty usage, they offer home DIYers a cheap alternative for infrequent cutting when accuracy and clean cuts are not required.

Panel saws can have one main saw blade, or a scoring along with a main saw blade. Scoring is used to create a groove, especially in double side laminate before the main saw rips the piece apart, to avoid chipping. The scoring saw rotates in an opposite direction, as the main saw to avoid chipping.

3.Edge Banding Machines-Panel Saw Images

4.Edge Banding Machine-Panel Saw Specifications

Maximum cutting length2800mm2800mm

Maximum cutting thickness80mm80mm

Main Blade sizeΦ305×Φ30mmΦ305×Φ30mm

Slot Blade sizeΦ120×Φ22mmΦ120×Φ22mm

Main saw shaft speed4000/5000rpm4000/5000rpm

Slot saw shaft speed9000r/min9000r/min

Main saw motor power5.5kw4kw

Slot saw motor power1.1kw1.1kw

Total power6.6kw5.1kw

Suction mouthΦ100×1Φ100×1

Weight800kg770kg

Box set dimensions3400×1150×1100mm3400×1100×1100mm

5.FAQ of Edge Banding Machines-Panel Saw

1) What can we do for you?

.We can ensure the quality of the Edge Banding Machines-Panel Saw and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Ask you cabinet door, what edge is good? Aluminum alloy U type edge banding strip? Or PVC edge banding? Personal feel of aluminum alloy more beautiful, but aluminum alloy U type edge banding, afraid the right angle is too sharp, PVC sealing edge with that kind of glue didn't want to be good, still need to repair edge, trouble you talk about Oh, good and bad??

- PVC edge banding and wood edge can be used, PVC to machine wood edge brush

- Q: Do medals, wooden doors, heat transfer, edge banding machine, which sell well? Quality assured? Good after-sales service?

- You can use a device, that is, according to your product shape, if the door and medal shape exactly the same, you can completely use a device,. If not the same, it is necessary to make different knives according to your products, and hot stamping rubber wheel. For further information, call me; 14763909633; Li Jichao. I am Lin Woodworking Equipment Co. Ltd. Please call me again before the next Baidu (stamping edge machine) Lin supply special medal wooden rhinoceros stamping sealing machine. Ha-ha

- Q: Is it good to have edge metal or PVC at home?

- The metal is strong and the PVC is worse, but the edges of the PVC will not be scratched

- Q: Floor banding how to install, please expert pointing

- Cool breeze, green floor, tell you: use nails and glue.

- Q: Cross stitch edge ornaments how?

- LZ Hello: I according to their own experience, the double-sided stitching stitch finishing a bit, so that we can study together. The steps are as follows: before stitching, you must make sure all the embroidery surfaces have been finished, including the edges, too. Suture: 1, a single line from transparent, stock into the needle, a knot "red scarf knot" spare, and stretched at the other end. 2, take a piece of embroidery, embroidery stitches along the surface from the back edge (arbitrary) tied to the embroidered into the front, then from the adjacent needle, and from the "red scarf buckle knot" in the inserted and tightly fixed on the cloth line naturally. 3, take another piece of embroidery and back-to-back completely overlap, along the outer edge of the suture stitch eye, pin is the most common on the needle and needle "," needle line must be the most outer contour overlap stitch. 4, close to the starting point when the seam, to the amount of silk into, and then sealing. 5, in order to avoid the thread exposed, the thread can hold after the needle line pull plug silk belly ", and then in a CM position of the needle is pulled out, the line will cut off the root of qi. 6, cut, along the suture line out of a grid position, cut off the excess surface can. Finally, the lanyard, bell and other small accessories in the proper position to be accomplished on O (a _ U) O happy happy happy every day!

- Q: The more detailed the better, as long as the edge and veneer veneer detailed steps, other steps do not use.

- The answer to the 80home fashion furniture is very standardPlate sanding refers to the customer will need to add the wood edge or due to stitching caused by surface roughness of substrate enough through the wide breadth sanding machine for sanding processing, mainly in order to achieve the purpose of smooth surface for hot pressing plate is not uniform throughout the compression of thick sand is light foaming. An attached sander function, sometimes plate thickness does not meet the regular customer needs, only by sanding again and again to reduce the thickness of the thickness of demand until close to the customer so far. Because the accurate thickness of sanding machine can be accurate to about 10S, so with the caliper can reach the thickness of purpose.A process is in fact in the preparation of the veneer veneer veneer cutting industry. Because of the impact of natural conditions, the conventional width veneer are generally restricted in a dozen centimeters (some more narrow, of course there are some more wide), so must pass before veneer and veneer edge stitching, there will be a lot of white edge (also is the color difference and the middle) if you do not cut off together will be very ugly, in order to make the stitching seam is not too obvious to do so to seal, then as long as two edges to splice line can be better. There are special cutting veneer veneer cutting general machine, cutting machine blade length of two or three meters, basically can satisfy the needs of

- Q: What is the difference between edge press and edge sealing machine?

- Did you say that kind of tin press? You can refer to Yangzhou as a margin press, and their products are used for processing iron sheet. You said the edge machine should be processed clothes.

- Q: I would like to do their own solid wood particle board edge banding. Use hot melt adhesive. But there is no machine. Can I ask if artificial can do? Quality is good?

- Yes, now all use PUR hot melt adhesive for edge banding, so environmental protection tasteless; you want to use ordinary hot melt stick, then the strength of bonding can be choked..

- Q: What is woodworking edge banding machine?. What role does it play?

- There are many kinds of woodworking machinery, such as coating machine, laminating machine, engraving machine and so on, in which the edge sealing machine is one of them. It is a kind of machine tool that can automatically complete the work of edge sealing of sheet metal. It has linear edge banding machine and curve special edge banding machine (portable), but it uses portable edge banding machine less. Edge banding machine according to the degree of automation points, there are fully automatic and semi-automatic. Whether it is automatic or semi-automatic edge banding machine, its structure is the fuselage, processing components and control systems. Full automatic and semi automatic the main difference lies in the different processing parts, semi automatic gluing, generally only: upper and lower edge, trimming, polishing, automatic: pre milling, gluing, sealing, block, repair, rough finishing, copying tracking, scraping, polishing, slotting. These two pieces of equipment are used for edge sealing of panel furniture. Under normal circumstances, semi-automatic edge sealing machine is enough. In addition, the price of more than 20000, semi automatic, automatic more than 50000.

- Q: Cabinet box, use 18 fir finger to connect board, this still needs sealing edge??

- If it is used in the kitchen, does not advocate the use of Chinese fir finger board, whether it is moisture-proof or environmental protection, etc., will not be better than the current overall use of melamine moisture-proof board!

Send your message to us

Portable Edge Bander KM600D Edge Banding Machines of Different Kinds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords