Cmax Timer Beam Formwork with Strong Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

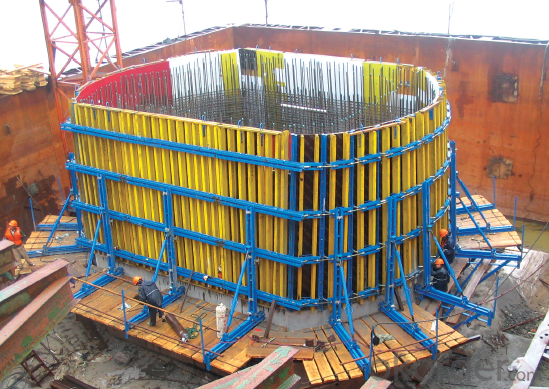

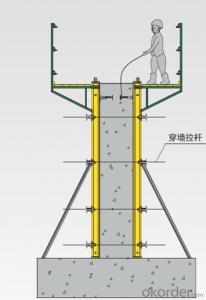

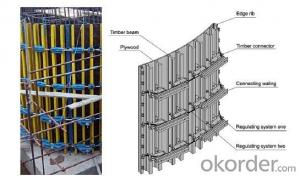

1. Structure of Timber Beam Wall Formwork Description Timber beam wall formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost. The formwork is made of plywood, which is a coated special plywood using in the formwork systems where high requirements are set on the concrete surface and the times of reuses.

2. Main Features of Timber beam wall formworks -convenient for construction -Standardized production lines -Robust caps at the end of the girders protect against damages -Easy to control the quality -Strong Ablitiy in construction 3. Timber beam wall formwork Images

4. Timber Beam Wall Formwork Specifications -convenient for construction -easy to control the quality -easy, rapid and economical. Timber beam column formwork is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.FAQ of Timber Beam Wall Formwork 1) What can we do for you? .We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers. .We can provide you the professional technical team. .We can provide professional building proposal for your projects.

2) What about of our after-sale services? . Response will be carried out in 24hours after receiving any complain or request. . Any formwork cost can be refund after order is confirmed. . If the products are not based on the requirements, there will be the relevant compensations made for you.

3) What about the package and shipping time? .Packing: wood package and adhesive tape .Shipping: by sea Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks. Other mass qty of Timber-beam Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days. 4) What promises can be done by us? . If interested in Timber-beam Formwork, please feel free to write us for any QUOTE. . If printing required, please advise asap because the whole set need much more time to complete. . Please DO check goods when courier knocks your door and contact us asap if any issue. |

- Q: What is the use of building wall formwork support? Thank you

- In the construction for concrete cast-in-place construction formwork supporting structure, widely used in steel or timber beams assembled into the template bracket

- Q: Technical specification for construction formwork safety JGJ162-2008 who has made me please

- Safety code for construction formwork JGJ 162-20081 General Provisions1.0.1 for the implementation of the construction project template construction of China's safety production principles and policies to achieve advanced technology, economic and reasonable, easy to apply and to ensure safety in production, the development of this specification.

- Q: 1, JGJ162-2008 construction formwork safety technical specification;2, JGJ130-2011 construction fastener type steel pipe scaffolding safety technical specifications; the friend has. Send me thanks

- General principles for the implementation of 1.0.1 in the construction of formwork engineering in China to implement the principles and policies of safe production, to achieve advanced technology, economic and reasonable, easy to apply and to ensure safety in production, the development of this specification. 1.0.2 This specification is applicable to the design, manufacture, installation and dismantling of the cast-in-place concrete engineering formwork system in construction. 1.0.3 template design and construction, from the actual situation of engineering, reasonable selection of materials, scheme and construction measures; should satisfy the template in the transport, installation and use of the strength, stability and stiffness requirements, and should give priority to the finalization, standardization and template template support components, reduce production and installation work to improve the reuse rate. The design, manufacture, installation and removal of the 1.0.4 construction formwork shall be in conformity with the requirements of this code, and shall comply with the relevant provisions of the state.

- Q: 86335 template support, what is the concept of those advantages

- 86335 new formwork support structureDigital steel formwork support composite structureAt present, in the construction for concrete cast-in-place construction formwork supporting structure, widely used in steel or timber beams assembled into the template bracket, built into the scaffold to form a bracket supported by steel or wood, and with steel formwork concrete construction. The problem is to build and assembling workload, low construction efficiency, labour and material consuming and poor quality, waste of resources, not beautiful and difficult to adjust

- Q: Since the building, and I would like to ask some of the basic knowledge to the construction of a unified drawing, plus or minus 0 and the height of the drawings, the roof slope requirements. Now the blue steel reinforced concrete inclined roof beams or do. Here we use multiple beams, and the waterproof, thermal insulation, in tile. Anyway, many shortcomings is wood, attic space basically scrapped, there is a fire started...I would also like to use concrete flat top, that is, do not let, more depressed.If I can use wooden beams, waterproof SBS, hanging plastic extruded board?The construction of plastic extruded board in inclined roof beams hung strong? Construction is not difficult?As well as the 8X11 meters of the roof, 30 degrees slope, sloping roof concrete cost about? I feel modeling and cloth reinforcement are very troublesome, expensive cost estimation

- Here we use multiple beams, and the waterproof, thermal insulation, in tile.What is the waterproof tile?Timber can do SBS? Don't understand what you mean, if not the construction of SBS membrane surface; or SBS polymerization coating applied to the beams? Feel that is not necessary, just like a bit of preservatives, like the outside paint brush.

- Q: What is the building template support

- The main: length may be 1.17 meters and 4.39 meters between any adjustment for short distance, main keel balcony and bathroom, small room.Vice: the length of 1.15 meters, 0.8 meters and 0.4 meters specifications.Support rod: height can be adjusted between 2 meters and 4.80 meters, such as the height of the building with the connecting rod arbitrarily high.

Send your message to us

Cmax Timer Beam Formwork with Strong Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches