CMAX Series PE,PP And Wood, PVC And Wood (Foamed) Panel Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard wooden case |

| Delivery Detail: | 20 working days |

The extruder is equipped with the temperature controlling gauges which have the advantages of high precision temperature controlling, easy and reliable operation.

The vacuum calibration table equipped with the strong cooling device which ensures the cooling effect. Caterpillar type haul off unit, equipped with the precise speed reduction motor and inverter, has the advantages of reasonable structure,powerful and stable haul off force. The cutter has the reliable and accurate cutting effect.

The stacker has the movable stacking trolley and special made rubber protection layer to prevent the product from being scratched. The downstream equipment of this extrusion line uses the programmable computer or domestic made controlling system for stable and reliable operation.

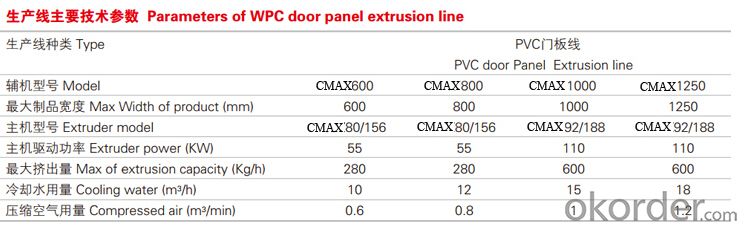

Technical parameters

Product show:

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q: What raw material does the extruder use?

- An extruder in which an air vent is disposed at the center of an exhaust extruder to allow removal of air and volatiles from the processed plastic. The main machine of plastic extruder is plastic extruderIt consists of an extrusion system, a drive system and a heating and cooling system. 1. extrusion system extrusion system includes screw, cylinder extrusion die head, extrusion die head, molding parts of the extruder. Also known as extrusion die, extrusion die.

- Q: What is the adjustment method of China's extrusion machine die?

- The adjusting method of the die is as follows: (data refer to China. Extruder)(1) air to mold: adjust the die before production, adjust the distance between the mold core and the die suite evenly with the naked eye, and then screw the die screws.

- Q: Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part.

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat, because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- The extruder is a constant torque load. The original configuration is usually a DC governor + DC motor. When using a DC motor, the current is usually constant during the speed rise.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- How big is it? Not too big. I suggest using a 40 or 30 too big block. You have to use a special break knot.

Send your message to us

CMAX Series PE,PP And Wood, PVC And Wood (Foamed) Panel Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches