CMAX PS Foamed Picture Frame Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wooden case |

| Delivery Detail: | 30working days after receiving the prepayment |

PVC PS Plastic Foamed Profile Production line

This line can produce high quality low foam profiles for users.

This production line is mainly composed of extruder and SJBZ low foam profile auxiliary machine combined with advancement, reliability and practicability. This line can produce high quality low foam profiles for users.

CMAX Series PS Foam Profile Extrusion Line, consists of single screw extruder and the special co-extruder, with the cooling water tank, hot stamping machine system, haul-off unit, and stacker.

This line with imported ABB AC inverter control, imported RKC temperature meter etc. and features of good plasticization, high output capacity, and stable performance etc.

The hot stamping machine system combined foreign technology, by the hot stamping embossing method, transfer the

coating layer from the film to the PS foamed profile. The machine with good appearance, stable performance, accurate & easy operation.

By adjust the embossing wheel the machine can work on various of different profiles.

Working together with the main extruder and other extrusion down steam equipments, this line is popular as the latest developed producing line.

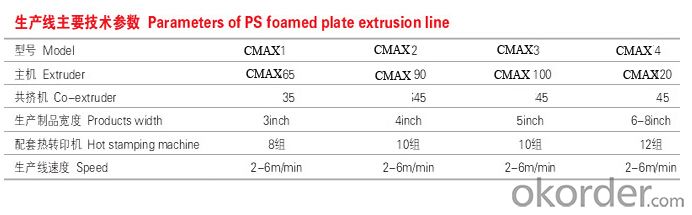

Main technical parameters:

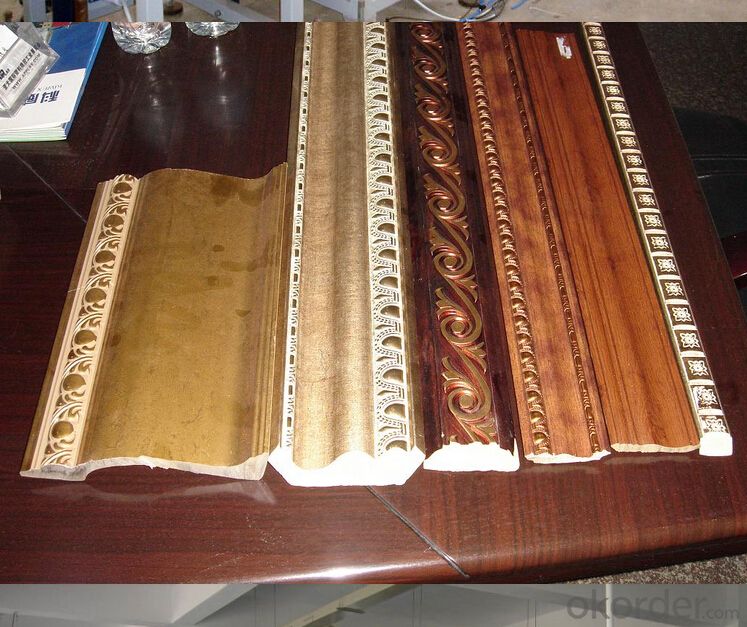

Product show:

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- Is that settled? This technology is not available online! No one wants to say free, need technical contact me!

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- I am a professional pipe mold, can you say more details?

- Q: What is the adjustment method of China's extrusion machine die?

- The adjusting method of the die is as follows: (data refer to China. Extruder)(1) air to mold: adjust the die before production, adjust the distance between the mold core and the die suite evenly with the naked eye, and then screw the die screws.

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc.

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- There is a kind of broken engineering material. I wonder if you can find it

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

Send your message to us

CMAX PS Foamed Picture Frame Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords