CMAX HDPE/PP/PVC Vertical Type Double Wall Corrugated Pipe and PVC Ribbed Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, or customized |

| Delivery Detail: | 35 days after deposit received |

Specifications

1. good quality and good material

2. easy operation and labor saving

3. high output and high reputation

Properties: DWC pipe is mainly used for water drainage system. It is a fully computer controlled line. It features high and stable output capacity, and highly automatic operation. For HDPE, you can choose high efficient single screw extruder. For PVC, you can choose conical twin-screw extruder or parallel twin- screw extruder. Forming system consists mould and corrugator. Mould blocks can be easily changed and they have air or water cooling system. The belling process is on line. High precision cutting can be guaranteed by cutting machine. The production line can also be equipped with SIEMENS PLC system.

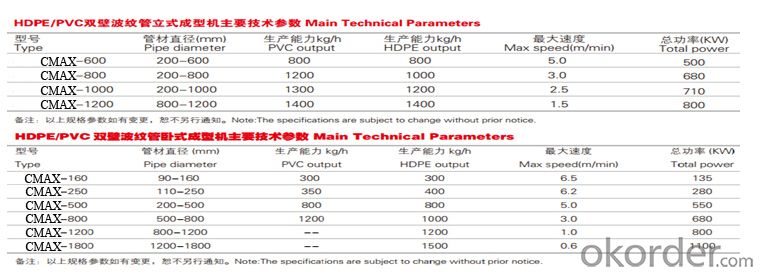

Technical parameters:

Features of Production line

1. It adopts special screw and barrel,ensuring plasticizing quality and high transparency

2.Special designed extrusion die head has layer control,each layer thickness can be adjusted freely

Pictures of PVC Plastic Steel Spiral Pipe Equipment

For more information, you may contact with me directly, and i would give satisfying help.

Packaging & Shipping

This machine would be packed with steel frame and plywood panels.

It is easyier to get through customs inspection.

User manul would be printed out, and be put in the shipping box with machine. And PDF copy would be sent to you for more convenience.

Our Services

OEM service offered.

Engineers available for overseas customer, for machine trial and teaching.

Suggest related material and mold for you, tury-key business to save your time.

- Q: when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- You can adjust the proportional gain, and if you don't move, the parameter has this problem, you should check to see if you really lost the pulse

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- When making documents, they are not in accordance with the actual situation.

- Q: What are the common extrusion molding products?

- Extrusion molding products are as follows:1 、 plastic pipe, for example: water pipe up and down;2, plastic profiles, such as: doors and windows, plastic steel profiles.3, plastic plates, such as: wood plastic doors, plastic doors,4, plastic sheet (sheet and board is the difference between the thickness, thin, thick plate), such as: mobile phone membrane.

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- They can see it moving.God doesn't need itSometimes you hear, fifth hand material,Cool sounds in the swirling smokeCoagulation together, I have left their land,Yesterday was a similar experience, ha ha

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

Send your message to us

CMAX HDPE/PP/PVC Vertical Type Double Wall Corrugated Pipe and PVC Ribbed Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches