Chrome Added Deformed Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

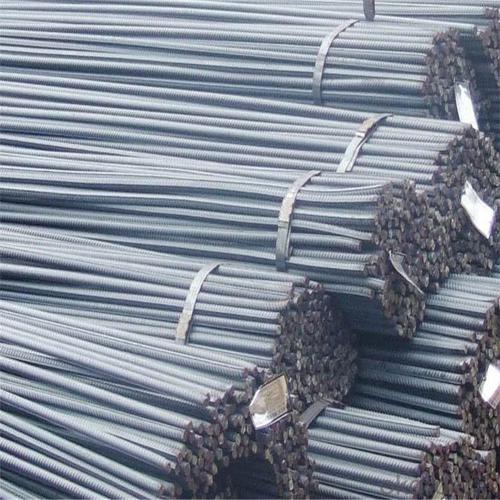

Chrome Added Deformed Steel Round Bars

Description of Chrome Added Deformed Steel Round Bars

1, Diameter: 5.5mm-10mm Chrome Added Deformed Steel Round Bars

10m- 40mm Chrome Added Deformed Steel Round Bars

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Chrome Added Deformed Steel Round Bars

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Chrome Added Deformed Steel Round Bars

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel perform in radiation shielding applications?

- Special steel is renowned for its outstanding performance in shielding against radiation, widely recognized for its unique properties and composition. It is an ideal choice in safeguarding against harmful radiation due to its exceptional qualities. One significant advantage of special steel is its remarkable density, which allows for the effective absorption and attenuation of radiation. This attribute enables it to serve as a barrier, effectively preventing the penetration of harmful radiation into sensitive areas. By significantly reducing radiation exposure, special steel plays a crucial role in diverse industries, including nuclear power plants, medical facilities, and aerospace applications. Furthermore, special steel possesses excellent mechanical strength and durability, ensuring long-lasting and reliable radiation shielding. It can withstand extreme conditions while maintaining its effectiveness over time. This durability is particularly vital in environments with continuous or ongoing radiation exposure. Moreover, special steel exhibits high resistance to corrosion and degradation, making it indispensable in radiation shielding applications. This resistance ensures the material remains intact and can provide the necessary protection against radiation for an extended period. As a result, frequent maintenance and replacement are minimized, leading to cost savings and improved operational efficiency. Additionally, special steel can be customized to meet specific requirements, allowing for tailored designs and configurations. This flexibility enables the development of radiation shielding solutions optimized for the unique needs of various applications. Whether it involves shielding panels, containers, or enclosures, special steel can be adapted to provide the most efficient and effective radiation protection. In summary, special steel excels in radiation shielding applications due to its high density, mechanical strength, durability, corrosion resistance, and customization capabilities. It offers reliable and long-lasting radiation protection, ensuring the safety of personnel and equipment in industries where radiation exposure is a concern.

- Q: What are the different surface treatment methods for special steel?

- Some of the different surface treatment methods for special steel include heat treatment, plating, coating, and nitriding. Heat treatment involves heating and cooling the steel to improve its hardness, strength, and ductility. Plating involves applying a thin layer of metal, such as zinc or chrome, to enhance corrosion resistance. Coating methods like painting or powder coating provide a protective layer and can improve aesthetics. Nitriding involves introducing nitrogen to the steel's surface to increase hardness and wear resistance.

- Q: What are the properties of shock-resistant alloy steel?

- Shock-resistant alloy steel is a type of steel that possesses specific properties that make it highly resistant to shock and impact. These properties include high tensile strength, toughness, and hardness. It is also known for its ability to withstand sudden changes in temperature, making it suitable for applications in extreme environments. Additionally, shock-resistant alloy steel has excellent fatigue resistance, corrosion resistance, and wear resistance, making it ideal for use in industries such as aerospace, automotive, and defense.

- Q: How does special steel perform in high-vibration environments?

- Special steel is specifically designed to perform well in high-vibration environments. Its unique composition and properties allow it to withstand and absorb vibrations, reducing the risk of structural damage, fatigue, and failure. Special steel's high strength, durability, and resistance to corrosion make it an ideal choice for applications where vibrations are a concern, ensuring reliable and long-lasting performance.

- Q: How is high-temperature alloy steel used in the production of heat exchangers?

- High-temperature alloy steel is commonly used in the production of heat exchangers due to its exceptional corrosion resistance, high strength, and ability to withstand extreme temperatures. It helps in maximizing the efficiency of heat transfer by maintaining structural integrity and preventing any degradation caused by the harsh operating conditions.

- Q: How does special steel ensure dimensional stability?

- Special steel ensures dimensional stability through a combination of factors such as controlled composition, precise heat treatment, and careful manufacturing processes. The specific composition of special steel is designed to have a lower coefficient of thermal expansion, which means it expands and contracts less with changes in temperature compared to regular steel. This ensures that the dimensions of the steel remain stable even under varying temperature conditions. Additionally, the heat treatment process further enhances the dimensional stability by refining the microstructure and reducing internal stresses. The careful manufacturing processes, including precise machining and quality control, also contribute to maintaining dimensional stability in special steel products.

- Q: How does special steel contribute to the dimensional stability of products?

- Special steel contributes to the dimensional stability of products through its unique properties and characteristics. One of the key factors is its high level of hardness, which allows it to resist deformation or changes in shape and size under varying temperature and load conditions. This hardness ensures that the product maintains its intended dimensions and shape, even when subjected to external forces or thermal fluctuations. Moreover, special steel often possesses excellent thermal conductivity, enabling it to efficiently distribute and dissipate heat. This property helps prevent localized heating or cooling, which can cause dimensional changes in materials. By maintaining consistent temperatures across the product, special steel minimizes the risk of warping, expansion, or contraction, thereby ensuring dimensional stability. Another aspect that contributes to dimensional stability is the low coefficient of thermal expansion of special steel. This coefficient measures the amount of expansion or contraction a material undergoes in response to temperature changes. Special steel's low coefficient means it experiences minimal dimensional changes when exposed to temperature variations. This characteristic is particularly crucial in applications where precise tolerances and tight dimensional control are required, such as in aerospace or automotive industries. Furthermore, special steel often possesses enhanced corrosion resistance, which helps prevent rusting or degradation of the material over time. Corrosion can lead to changes in the shape and dimensions of products, compromising their dimensional stability. By using special steel, manufacturers can ensure that their products maintain their original dimensions and structural integrity, even in harsh or corrosive environments. Overall, the unique properties of special steel, such as high hardness, excellent thermal conductivity, low coefficient of thermal expansion, and corrosion resistance, all contribute to the dimensional stability of products. By incorporating special steel into the manufacturing process, companies can produce high-quality products that maintain their precise dimensions and shape, ensuring reliability and longevity for end-users.

- Q: Can special steel be used in the beverage manufacturing industry?

- Yes, special steel can be used in the beverage manufacturing industry. Special steel, such as stainless steel, is commonly used in beverage processing equipment due to its corrosion resistance, hygienic properties, and durability. It is particularly suitable for manufacturing tanks, pipes, valves, and other components that come into contact with beverages, ensuring a high level of safety and maintaining the quality of the products.

- Q: What are the requirements for special steel used in aerospace defense applications?

- The requirements for special steel used in aerospace defense applications are quite stringent due to the critical nature of these applications. Some of the key requirements include: 1. High strength: Special steel used in aerospace defense applications must possess high strength to withstand extreme conditions and loads. This is essential for ensuring the structural integrity of aircraft and defense equipment. 2. Excellent corrosion resistance: Aerospace defense applications often expose the steel to harsh environments, including moisture, saltwater, and chemicals. Therefore, the steel must have exceptional corrosion resistance to prevent degradation and maintain its performance over time. 3. High temperature resistance: Special steel used in aerospace defense applications must have the ability to withstand high temperatures without losing its mechanical properties. This is crucial for components that operate in high-temperature environments, such as jet engines and rocket nozzles. 4. Fatigue resistance: The steel should be able to resist fatigue failure caused by cyclic loading, as aerospace defense applications often involve repeated stress cycles. Fatigue resistance ensures that the steel can endure long service lives without failure. 5. Lightweight: Weight reduction is a critical factor in aerospace defense applications to enhance fuel efficiency, increase payload capacity, and improve overall performance. Therefore, the special steel used should have a high strength-to-weight ratio, allowing for lighter structures without compromising strength. 6. High purity and cleanliness: The steel used in aerospace defense applications must have a high level of purity and cleanliness to minimize the presence of impurities and defects. This is crucial to ensure the reliability and longevity of the steel in demanding operational conditions. 7. Compatibility with other materials: Special steel used in aerospace defense applications should be compatible with other materials commonly used in these applications, such as aluminum alloys and composite materials. Compatibility ensures a reliable and efficient integration of different components and structures. Meeting these requirements often involves using advanced manufacturing techniques, such as vacuum melting, precise alloying, and heat treatment processes, to achieve the desired properties. Additionally, strict quality control measures, including non-destructive testing and material certification, are crucial to ensure the performance and reliability of special steel in aerospace defense applications.

- Q: What are the environmental considerations associated with special steel production?

- The environmental considerations associated with special steel production include the emission of greenhouse gases, such as carbon dioxide, during the manufacturing process. Additionally, the extraction of raw materials, such as iron ore and coal, can lead to habitat destruction and contribute to deforestation. The disposal of waste materials, such as slag and dust, also poses challenges as they can contaminate soil and water sources if not properly managed. Efforts are being made within the industry to reduce environmental impacts through the adoption of more sustainable practices and the use of cleaner technologies.

Send your message to us

Chrome Added Deformed Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords