Chromated Mill Finish Aluminum Coil Car Aluminum Alloy Metal

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

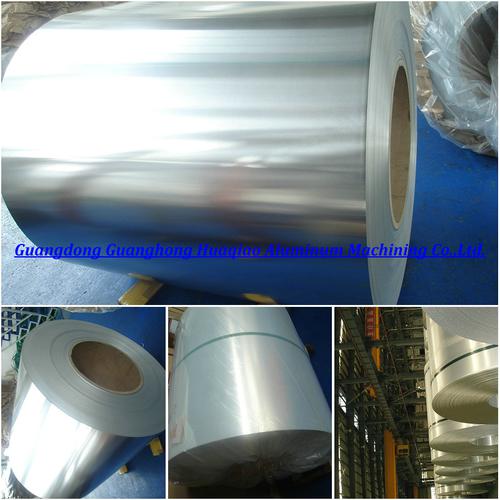

Color coated aluminum coil is a material with excellentacid-resistance and alkali-resistance. The coating layer is even with brightcolor to last for a very long time. It is a green decoration material with thecharacters of environment protection, flame-resistance, and groovy colors. In nowadays, the color coatedaluminum coil has become the popular material for top grade decoration. With our advance professional aluminum coated technique, wecan custom various aluminum coils ,like coated aluminum coil , Color coatedaluminum coil , embossed aluminum sheet with the color and size which youdemands.

1) Process: pre-treatment, continuous painting and baking for times.

2) Material: high quality material, aluminum sheets from South WestAluminum Industry Company in China, pre-treatment material from Henkel &Chemtell from Germany, more than 70% of PVDF coating from PPG Corp., the USAand polyester from Sweden Becker Industrial Coating Co., Ltd.

3) Our products can keep excellent quality and stability.

4) Thickness: 0.06 - 1.0mm; width: 20 - 1,590mm

Applications:

The aluminum coils are widely used in ACP/curtainpanel/honey comb panel/shutter/roofing and most of the decoration areas. Withthe superior quality and advanced management, our products had been export toEuro/North America /East Asia and many other areas and countries.

| Aluminum-plastic Composite Panel is called for short ACP or APCP. It’s a new material which is made of a series of technological process, the surface is the aluminum sheet of surface treatment and paint coating and the core is polyethylene plastic board.

|

| Aluminum Corrugated Composite Panel is full aluminum alloy composite panel which is composed of aluminum alloy front-panel, bottom plate and corrugated aluminum core vacuum.

SK coated aluminum coil, the surface is coated with PVDF, perfect weather resistance and excellent workability: various processing method of cutting, connect, bending, round bending and others. It is ideal material for aluminum corrugated composite panel. |

| The inside and outside layer of aluminum honeycomb panels are aluminum alloy sheet, intermediate sandwich material is hexagonal aluminum foil honeycomb core, honeycomb core is bonding composed of structural adhesive and aluminum alloy surface layer plate.

SK coated aluminum coil, The surface can be coated PVDF or PE by customer requested colors, the back is epoxy. It is ideal material of aluminum honeycomb panels making. |

| Metal exterior wall insulation board surface is color coated aluminum sheet, and aluminum sheet can be according to design request to choose facing design, color or roll forming for specified grain making, basically for adornment effect, and also have good weather resistance, corrosion resistance and self-cleaning. The middle layer is rigid polyurethane foam with fine warming insulation performance.

SK coated aluminum coil, The surface coated PVDF with perfect weather resistance, and also can be embossed for customer request. It is good choice for exterior wall insulation board manufacturer. |

- Q: Can aluminum coils be used in the production of heat exchanger fins?

- Indeed, aluminum coils have the capability to be employed in the manufacturing process of heat exchanger fins. The utilization of aluminum as a material for heat exchanger fins is quite prevalent owing to its exceptional thermal conductivity, lightweight composition, and resistance against corrosion. These attributes render it a perfect substance for the efficient transfer of heat, ensuring both sturdiness and long-lasting performance. The ease with which aluminum coils can be shaped into intricate fin designs further enhances the surface area available for heat exchange. Moreover, the abundant availability and cost-effectiveness of aluminum make it the favored selection for the production of heat exchanger fins across a multitude of industries, including HVAC, automotive, and refrigeration.

- Q: What are the different edge treatments available for aluminum coils?

- Aluminum coils offer a variety of edge treatments, each with its own benefits and uses. 1. Mill Finish: The aluminum coil remains as it is after manufacturing, without any additional treatment. This option is ideal for industrial or construction applications that prioritize functionality over aesthetics. 2. Trimmed Edge: The edges of the aluminum coil are carefully trimmed to remove sharp edges, ensuring safe handling and reducing the risk of injury during fabrication or installation. 3. Deburred Edge: Similar to the trimmed edge treatment, the deburred edge involves eliminating burrs and sharp edges from the coil's edges. This is important when the aluminum coil will come into contact with other materials or surfaces to prevent scratches or damage. 4. Rolled Edge: The edges of the aluminum coil are rolled to create a smooth, rounded edge. This not only enhances the coil's appearance but also provides additional protection against corrosion and damage. 5. Beveled Edge: An angled cut is made on the edges of the aluminum coil to achieve a sloping edge. This treatment is commonly used in architectural applications where a sleek and modern look is desired, and it also facilitates easier welding or joining of the coil. 6. Hemmed Edge: The edges of the aluminum coil are folded or bent to create a hem-like finish. This treatment adds strength and rigidity to the coil, making it suitable for applications that require durability or structural integrity. 7. Painted or Powder Coated Edge: The edges of the aluminum coil are painted or powder coated to match the color or finish of the rest of the coil. This is often done for applications where the coil's edges are visible, achieving a seamless and consistent appearance. Ultimately, the choice of edge treatment for aluminum coils depends on the specific needs of the application, considering both functionality and aesthetics.

- Q: Are aluminum coils suitable for coil slitting applications?

- Yes, aluminum coils are suitable for coil slitting applications. Aluminum is a versatile and lightweight material that can be easily processed and slit into various widths, making it ideal for industries like automotive, construction, and packaging. Its high strength-to-weight ratio and corrosion resistance make aluminum coils a reliable choice for coil slitting applications.

- Q: Can aluminum coils be used in the production of heat exchangers?

- Yes, aluminum coils can be used in the production of heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils allows for efficient heat transfer and helps in optimizing the overall performance of the heat exchanger.

- Q: Is it okay to combine copper with aluminum in case of minting or coin making? Thanks :)

- Well, there are aluminum alloys that have copper in them (although they usually have other metals also), so I don't think it would be a problem. If you're thinking of copper plated aluminum, there is the potential for a galvanic reaction (meaning like a battery cell) that could cause the coin to corrode and fall apart. It's the same problem with the current production of US cents (which are copper coated zinc).

- Q: How do aluminum coils compare to ceramic coils in terms of thermal conductivity?

- Aluminum coils have significantly higher thermal conductivity compared to ceramic coils.

- Q: What are the common surface defects or issues in aluminum coils?

- Some common surface defects or issues in aluminum coils include scratches, dents, stains, oxidation, and uneven coatings.

- Q: Can aluminum coils be used for electrical enclosures?

- Yes, aluminum coils can be used for electrical enclosures. Aluminum is a commonly used material for enclosures due to its excellent conductivity, lightweight nature, and resistance to corrosion. It provides good protection against electromagnetic interference and can effectively dissipate heat. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, making them suitable for electrical enclosures in different applications.

- Q: What are the different coil handling methods for aluminum coils?

- To ensure the safe and efficient handling and storage of valuable aluminum coils, there are various methods available. Here are several options: 1. Manual Handling: This approach involves the physical lifting and movement of aluminum coils using manual labor. It necessitates proper training and the use of personal protective equipment to prevent injuries. Manual handling is suitable when dealing with smaller coils or when specialized equipment is unavailable. 2. Forklift Handling: Forklifts are commonly utilized for the handling of aluminum coils. They come equipped with specially designed coil lifters or C-hooks, which securely lift and transport the coils. Forklifts offer a more efficient and quicker method for handling larger and heavier coils. 3. Coil Lifters: Coil lifters are specialized lifting devices specifically designed for aluminum coil handling. They utilize a combination of clamps and hooks to securely grip and transport the coils. Coil lifters are often used alongside cranes or forklifts. 4. C-Hooks: C-hooks are another commonly employed method for handling aluminum coils. These hooks are attached to cranes or other lifting equipment and are designed to securely cradle the coil. C-hooks facilitate easy and controlled movement of the coil and are suitable for coils of various sizes. 5. Coil Tippers: Coil tippers are utilized to tilt the coils horizontally or vertically, making loading or unloading easier. This method reduces the risk of coil damage during handling and enhances efficiency by enabling coils to be easily placed on or removed from racks or pallets. 6. Coil Carriers: Coil carriers refer to specialized trailers or trucks specifically designed for transporting aluminum coils. They feature built-in coil cradles or beds that securely hold the coils during transportation. These carriers often have adjustable supports to accommodate different coil sizes and prevent shifting during transit. Ultimately, the choice of coil handling method depends on factors such as coil size, weight, and specific requirements. It is crucial to select the appropriate handling method to ensure worker safety, prevent coil damage, and maintain the quality of the aluminum.

- Q: I am looking for a deoderant that doesn't contain aluminum that actually works. I have tried Tom's natural deoderant and didn't get to use it long enough to see if it worked because it really irritated my skin and caused it to burn and peel. I have also tried the one made by Adidas and it seemed to work pretty well through the winter months, but now that it is getting warm again I'm noticing that it isn't quite doing the job anymore.

- Try Crystal's they have the rock version which you have to wet before you use it and they also have he ready to use liquid. I find the liquid form to work best during the summer.

Send your message to us

Chromated Mill Finish Aluminum Coil Car Aluminum Alloy Metal

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords