Mill Finish Aluminum Zinc Alloy Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Specification:

Alloy: AA1050, 1060, 1100,AA3003, 3005, 3015, 5052, 5754, 5083,8011, etc

Temper: H14/16/18/22/24/32,HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm (Can be slitted)

Inner Diameter:508MM

Coil Weight:500kg-3000kg(Max.)

Application:Foil stock, Circles, Roofing, Can stock, Marine plate,Anti-slipery purpose in vehicles, packing and appliance.

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail:

Carton ,Woodenpallet with plastic protection packing ,standard seaworthy packing or as yourrequest.

Production Capacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

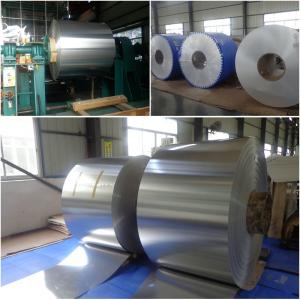

Production Line:

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 days after client’s deposit

- Q: How are aluminum coils coated or finished?

- Aluminum coils are commonly coated or finished through processes such as painting, anodizing, or laminating. Painting involves applying a protective layer of paint or coating onto the aluminum surface to enhance its appearance and protect it from corrosion. Anodizing, on the other hand, involves creating a controlled oxide layer on the surface of the aluminum, which provides durability, improved color options, and resistance to corrosion. Laminating is another method where a protective film or layer is added to the aluminum coil, providing additional protection and improving its aesthetic appeal.

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum coils.

- <p>Aluminum coils offer several advantages, including high thermal conductivity, which makes them efficient for heat transfer applications. They are lightweight and corrosion-resistant, which enhances their durability and reduces maintenance needs. Additionally, aluminum is a cost-effective material compared to other metals like copper. However, there are disadvantages such as lower strength compared to steel, which may limit its use in high-stress applications. Aluminum also has a higher coefficient of expansion, which can lead to issues in precision applications. Lastly, while it is recyclable, the recycling process can be energy-intensive.</p>

- Q: What are the different coil handling options available for aluminum coils?

- Aluminum coils have several options for handling, depending on the user's preferences and specific requirements. Some commonly used options include: 1. Coil Cradles: These are horizontal racks or frames that provide support and stability for aluminum coils during storage or transportation. They come in various sizes and designs to accommodate different coil dimensions. 2. Coil Cars: These mobile platforms have lifting mechanisms to easily move aluminum coils between different processing stations. They can be manually operated or automated, depending on the desired level of automation. 3. Coil Turnstiles: These rotating devices hold multiple coils vertically, allowing for easy access to individual coils without heavy lifting or rearranging. They are ideal for high-volume production environments that require quick coil changeovers. 4. Coil Upenders: Specialized equipment used to rotate or flip aluminum coils to change their orientation. They are useful for loading or unloading coils in a vertical position or for specific processes that require a particular coil orientation. 5. Coil Lifters: Specifically designed lifting devices for aluminum coils. They have adjustable arms or clamps to securely grip the coil for safe and efficient lifting. Available in manual, semi-automatic, and fully automated models. 6. Coil Tippers: Used to tilt or incline aluminum coils for various purposes such as coil feeding or inspection. They can be operated manually or powered by hydraulic or pneumatic systems. 7. Coil Stackers: Used to neatly stack and store aluminum coils vertically. They have adjustable arms or forks to accommodate different coil sizes, optimizing storage space and ensuring easy access when needed. These examples showcase the variety of coil handling options available for aluminum coils. Each option has its own advantages and suitability for different applications or industries. Careful consideration of specific requirements and constraints is essential when selecting the most appropriate coil handling solution.

- Q: wood aluminium windows?

- This is not a question?????? wood and aluminum are two different thing. FYI

- Q: Are aluminum coils suitable for heat exchanger applications?

- Yes, aluminum coils are suitable for heat exchanger applications. Aluminum is a lightweight and highly conductive material, making it an excellent choice for heat transfer applications. Aluminum coils offer several advantages in heat exchangers, such as high thermal conductivity, corrosion resistance, and ease of fabrication. They are commonly used in various heat exchanger systems, including air conditioning, refrigeration, and automotive applications. Additionally, aluminum coils can be easily formed into different shapes and sizes, allowing for greater design flexibility. Overall, aluminum coils are a reliable and efficient option for heat exchanger applications.

- Q: Why does the end face of aluminum coil have grease spots?

- Process one without coolant to see whether there are spots. There is a layer of alumina membrane on the blank face of aluminum coil, which will react with basic coolant when heating through processing.

- Q: Are aluminum coils compatible with different joining methods?

- Yes, aluminum coils are compatible with different joining methods. Aluminum is a highly versatile metal that can be joined using various techniques such as welding, brazing, soldering, and mechanical fastening. The choice of joining method depends on the specific application and the desired properties of the joint. Welding is commonly used to join aluminum coils as it provides a strong and durable bond. Several welding techniques like MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and resistance welding can be used depending on the thickness and type of aluminum alloy being joined. Brazing is another effective method for joining aluminum coils. It involves the use of a filler material that has a lower melting point than the base metal, which is heated to create a strong joint. Brazing is commonly used when the aluminum coils need to be joined to other dissimilar metals. Soldering is suitable for joining thin aluminum coils or when a lower temperature method is required. It involves melting a low-temperature alloy (solder) to join the coils together. Soldering is commonly used in electronics and plumbing applications. Mechanical fastening methods such as bolts, screws, rivets, or clips can also be used to join aluminum coils. These methods provide a reliable and removable joint, making them suitable for applications where disassembly may be required. In summary, aluminum coils are compatible with various joining methods, including welding, brazing, soldering, and mechanical fastening. The choice of joining method depends on factors such as the application, the type of aluminum alloy, and the desired properties of the joint.

- Q: What are the different hardness levels of aluminum coils?

- The hardness levels of aluminum coils are typically categorized into a range from soft to hard, with soft being the lowest hardness level and hard being the highest.

- Q: How are aluminum coils used in the electrical industry?

- Aluminum coils are widely used in the electrical industry for various applications such as transformers, motors, generators, and electrical transmission systems. These coils are used to create electromagnetic fields, which are essential for the functioning of these electrical devices. Additionally, aluminum coils are preferred due to their lightweight, high thermal conductivity, and cost-effectiveness compared to other materials.

- Q: what is the most likely charge for aluminum cation?the answer is +3, but why? how can i figure this out with different ones?

- This Site Might Help You. RE: what is the most likely charge for aluminum cation? what is the most likely charge for aluminum cation? the answer is +3, but why? how can i figure this out with different ones?

Send your message to us

Mill Finish Aluminum Zinc Alloy Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords