Ceramic Filter Plate for Alumina Making Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

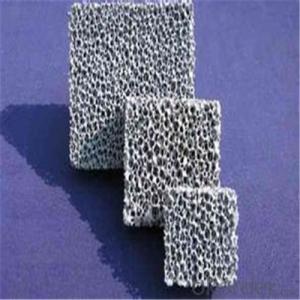

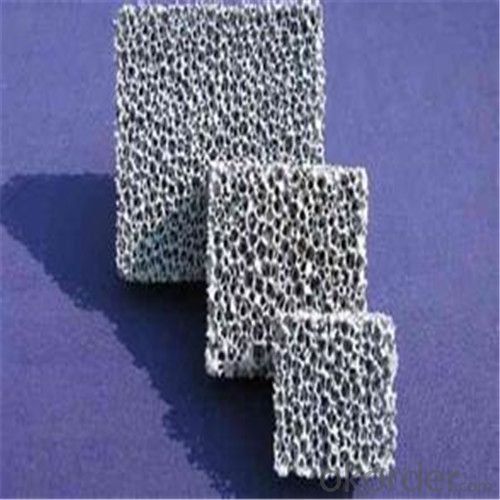

Ceramic Foam Filter for Alumina Making Industry

Composite of Ceramic Foam Filter for Alumina Making Industry

Ceramic Foam Filter is developed as a new type molten metal filters to decrease casting flaw in recent years. Foamed ceramics have the characters of light weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, chemical corrosion resistance and high temperature stability in molten metal. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less and the cast quality becomes much better.

Advantages of Ceramic Foam Filter for Alumina Making Industry:

Precise Dimension Tolerance

High Mechanical Strength

Chemical Stability and Corrosion-resistance for molten aluminum.

Phosphate-free, No Pollution for Environment

Purifying Liquid Aluminum, Improving Quality

Reduce Defects

Reduce Cost

Increase Yield Rate

Easy to Use

Size from 40-600mm available.

Ceramic Foam Filter for Alumina Making Industry Images

Specification of Ceramic Foam Filter for Alumina Making Industry:

Item | Unit | Alumina Foam Filter | Sic Foam Filter | Zirconia Foam Filter |

Bore Density | ppi | 10~80 | 10~60 | 10~40 |

Porosity | % | 80~90 | 80~90 | 80~90 |

Max.working Temperature | °C | 1100 | 1550 | 1700 |

Bending Strength | Mpa | 0.6 | 0.7 | 0.8~1.0 |

Compression Strength | Mpa | 0.7 | 0.8 | >1.2 |

Thermal Shock Resistance | times/1100°C | >6times | >6times | >6times |

SiC | % |

| ≥60 |

|

Al2O3 | % | ≥85 | ≤30 |

|

SiO2 | % | ≤15 | ≤10 |

|

ZrO2 | % |

|

| ≥95 |

Others | % |

|

| ≤5 |

application |

| Alumina and Alumina Alloy Non-ferrous | Grey Iron, Ductile Iron | Steel casting |

FAQ of Ceramic Foam Filter for Alumina Making Industry

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- That's a good question. I hope my answer will help you.Ceramic filter ceramic plate broken, nothing more than ceramic plate plug and ceramic plate rupture, you should be the problem of ceramic plate rupture.

- Q: What are the poor filtration effects of vacuum disc filters?

- The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- The working process of ceramic filter is: suction - drying - unloading - backwash - suction - drying - unloading - backwash...... In circulation, suction, the drying process is to make the slurry liquid by vacuum suction and capillary effect (usually water) through the filter media from the left, the filter cake on the filter medium (the two processes like device, through the pump) scraper discharge, discharge will complete a ceramic filter in the absorption cycle, slurry, drying process, some fine particles may enter the filter medium or stacked on the surface (a lot of pipeline internal filtration medium ceramic filter plate), these small particles will cause blockage of filter media lose permeability so that the filtering effect of variation, in order to reduce the possibility of blockage, ceramic filter will enter the backwash (this process is like a water jet device). Ceramic filter backwash is through the pressure of water, these small particles plug discharge ceramic filter board.

- Q: Can the plate filter press pass through the filter plate?

- Specific, it is necessary to choose the filter characteristics according to different materials. Plate and frame filter press: plate and frame filter press is an industrial realization of solid, liquid separation, plate and frame filter press is suspension, liquid-solid, liquid two phase, applied to chemical, ceramics, oil

- Q: Common troubles of ceramic filter

- The metering pump is not working properly and backwash water into the bucket of acid. The main reason is that the metering pump is not switched on, the diaphragm is worn out, the frequency is too low, and the check valve of the acid pipe and backwash pipe is worn out.

- Q: Microporous ceramic filter plate cleaning

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

- Q: What is the backwashing pressure of the ceramic filter?

- Ceramic filter is a kind of solid-liquid separation, dehydration drying equipment, such as dehydration pulp, mortar. The backwash of ceramic filter is to flush the filter medium (ceramic filter plate) with clean water with a certain pressure.

- Q: Can the ceramic plate filter the hot air?

- Ceramic filter is a new and efficient dehydration equipment. If users find the ceramic filter board surface suction effect is poor, or even do not suck slurry, we should promptly investigate the causes, so as not to affect production efficiency. I hope the following analysis will help you. First, the reasons for the ceramic filter.

Send your message to us

Ceramic Filter Plate for Alumina Making Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords