Alumina Ceramic Filter Plate for Aluminium Foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

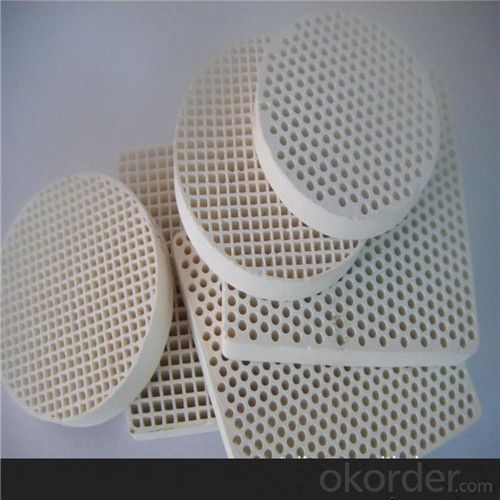

General Information of Ceramic Foam Filters

Alumina ceramic foam filters are widely used in filtering the alumina and alloys in foundries. With 80-90% porosity, the filters can effectively remove the alumina dross to improve the casting quality.

Features of Ceramic Foam Filters

Improving the steel casting quality

Excellent thermal shock resistance

High porosity with good strength

Applications of Ceramic Foam Filters

Carbon steel casting, steel alloy casting and stainless steel casting

Image of Ceramic Foam Filters

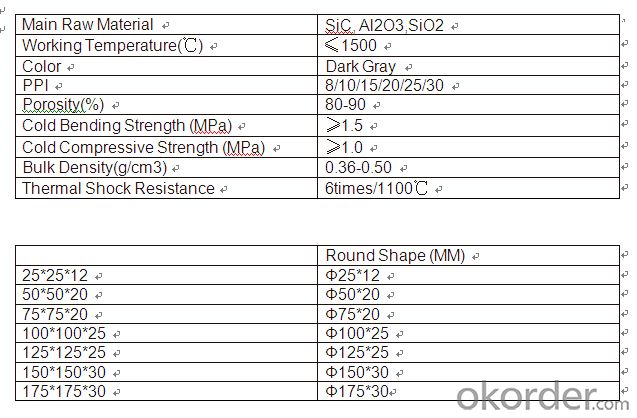

Technical Data of Ceramic Foam Filters

FAQ

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: What filter material are placed in the aquarium filter?

- Submerged in water. Submersible pumps and filter cotton (often replaced by sponge) installed in one, and some brands will also be installed heaters, which become multi-purpose fish farming equipment. When working, the water is absorbed into the filter in many directions, and the filtered water is returned to the water tank by other means. This filter because of its low price and popular beginners of all ages, but the effects from the use of view, only suitable for small fish density, on the flow and filtration requirements are not high, a small aquarium, "fish" will be built in filter (especially the heating function of the filter for seedling and foster) water tank. The effect is very good. The biggest disadvantage of this device is that when it stops working, a lot of dirt stuck to the filter runs back into the water.

- Q: Performance advantages of ceramic filter

- The base is provided with a slime recovery rotor, the rotor consists of a shaft, multistage ceramic filter disc, stripper plate, multi section water connecting pipe, pipe support plate, negative pressure connecting component dynamic disk; the rotor is in the recovery of coal slime liquid tank; the ceramic filter disc by a plurality of ceramic microporous plate cavity, located on the same axis of a ceramic plate cavity communicated through the outlet connection pipe.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- In addition, the temperature is one of the factors affecting the filter suction effect of ceramic filter. The lower the temperature, the worse the suction effect.Therefore, the ceramic filter plate, especially the ceramic filter plate after use, should be protected under low temperature environment.

- Q: Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

- Q: Can the plate filter press pass through the filter plate?

- Specific, it is necessary to choose the filter characteristics according to different materials. Plate and frame filter press: plate and frame filter press is an industrial realization of solid, liquid separation, plate and frame filter press is suspension, liquid-solid, liquid two phase, applied to chemical, ceramics, oil

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Ceramic filter medium is ceramic, ceramic generally resistant to strong acid, alkali, cleaning, it is best to use nitric acid, hydrochloric acid next, not recommended to use sulfuric acid.

- Q: The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q: What are the reasons for the program alarm of ceramic filter?

- If you say "lean" is the ceramic filter suction when the ceramic filter plate into a cake of thin, high water content, is the ceramic filter for their own reasons, can from the following aspects: the investigation considering this phenomenon is always so recently or just happened, if you have been so, probably because your selection is not suitable for pulp the ceramic filter (such as mud content, fine grain size, ceramic filter plate selection such as inconsistent or unqualified ceramic filter). If this anomaly has occurred recently, it is possible to change the ore condition, and the operation parameters of ceramic filters or the cleaning are not up to standard. You can check the vacuum system (vacuum generally ranges from -0.09 to -0.075MPa), backwashing system (generally refers to the filtered water recoil 0.07 ~ 0.12MPa), acid (HNO3 system standards), ultrasonic system is normal.

Send your message to us

Alumina Ceramic Filter Plate for Aluminium Foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords