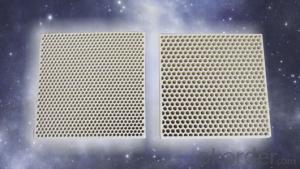

Ceramic Filter Plate with Excellent Thermal Shock Resistance

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

With excellent thermal shock resistance, high strength, high hole fraction and specific surface area, unique cell designs and advanced material, Extruded Ceramic Filters have a special function of attracting and capturing molten metal impurities on the cell internal walls.

Extruded Ceramic Filters are available in a range of cell sizes for Foundry & Casting applications. A wide choice of filter dimensions is also available for any gating system requireme。

Characteristics:

1.Improved casting quality;;

2.Improved machinability of castings;

3.Improved machine tool life。

Materials:

Cordierite, Mullite, Cordierite/Mullite, Zirconia

Application:

Grey iron, Ductile iron, Aluminum Alloy, Stainless steel.

Parameters

Items Al2O3(%) Compressive

Strength (Mpa) Porosity (%) Bulk Density

(g/cm3) Applied Temp(≤℃)

Parameters

≥42

>16 40~75 0.7~1.8 1550

- Q: What are the poor filtration effects of vacuum disc filters?

- Under normal circumstances, high vacuum, vacuum suction, high production capacity, filter cake moisture control is good. At present, some ceramic filters are equipped with two or multi-stage vacuum system to obtain almost absolute vacuum, and can reach 0.09 ~ 0.098MPa.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: Common troubles of ceramic filter

- Ultrasonic cleaning, ceramic filter plate cleaning is not clean. The main reason is that the power box is faulty, the power supply is burned out, the line is aging, the energy head is burned out, the ultrasonic box is broken down, and the water level in the pulp tank is too low;

- Q: What is the working pressure of the ceramic filter?

- Generally speaking, there are two kinds of working pressure of ceramic filter: vacuum pressure and reverse flushing pressure.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: Does the ceramic factory use hydrochloric acid?

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Selection of new ceramic filter plate:Because of the different size and characteristics of the pulp, different users need ceramic filter plates with different pore sizes (i.e., the average range of their surface pore size). In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- The backwashing system of ceramic filter is usually made up of water inlet, water inlet, pressure gauge, water filter and filtered water pressure gauge, and then connected to the inside of ceramic filter. Such as the discovery of ceramic filter recoil pressure became smaller or even no recoil pressure, you can carefully observe the surface of the ceramic filter plate is wet or ceramic filter plate wear without water injection at the discharge point, investigation and the reasons for the following aspects:Is the water inlet pressure or normal?How about the sealing performance of the water filter? Does the filter element need to be replaced?Is the recoil system piping (metal pipe, ceramic filter plate, connecting pipe, etc.) broken, leaking or dripping?Is the distributor valve properly installed and is it worn?Are there any cracks in the ceramic filter plate?Is the pressure gauge broken?The most likely reason is 1, 2, two, the best water should not be too dirty, filter should be replaced regularly. I hope the answer can help you.

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

Send your message to us

Ceramic Filter Plate with Excellent Thermal Shock Resistance

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords