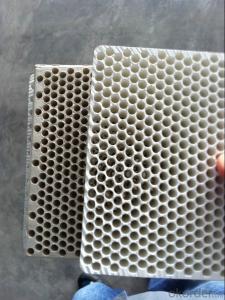

Ceramic Filter Plate Alumina Grinding Ball with Higher Hardness and Density

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

APPLICATION

Being the high quality grinding media, Alumina Grinding Ball is superior in higher hardness and density, better toughness and erosion resistance, as well as regular shape. It is widely applied in ceramic, cement, paint, pigment, chemical, pharmacy, coating and mining industries.

Typical Characteristics JIN GANG Alumina Grinding Ball

Item JG92-1 JG92-2 JG75 JG68

Al2O3+ZrO2(%) 92 92 73~78 68

Bulk Density(g/cm3) 3.65 3.6 3.25 2.9

Water Absorption(%) <0.1 <0.1 <0.1 <0.1

Wear Loss(‰) ≤0.1 ≤0.15 ≤0.2 ≤0.4

Hardness(Mohs) 9 9 8 7~8

Color White White White Yellow White

Application Glaze Milling,Tile body Milling Glaze Milling,Tile body Milling Glaze Milling,Tile body Milling Glaze or Tile body Milling

Raw Materials Calcined Alumina Calcined Alumina Zirconia,Calcined Alumina Refined Bauxite Powder

Forming Method CIP CIP CIP CIP

Diameter(mm) 0.2~70;Can be customized accordingly.

Note:

(1)Wear loss is tested according to the Chinese National Standard JC/T848.1-2000.

(2)Above technical data is typical test result,the real value may change within acceptable tolerance.

- Q: Performance advantages of ceramic filter

- A ceramic filter for fine coal mud recovery, there is a base, the lower part of the frame is provided with a fine slime liquid trough, the fine slime liquid material groove is provided with a liquid level controller, the slime liquid material at both ends of the groove is provided with a negative pressure water tank, the water tank is provided with a negative pressure suction connection assembly fixing the other side is provided with a vacuum pump pipeline, the pipeline is communicated with a vacuum pump and vacuum pump;

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- If it is found that the ceramic plate is broken, it should stop in time to replace the broken ceramic plate. Ceramic filter is produced by vacuum suction vacuum pump to the pulp in the water through the ceramic plate away, the surface aperture ceramic plate for several microns, so it can intercept the cake on the ceramic plate on the surface, if the ceramic plate is broken, a hole is a few millimeters, when the vacuum suction pump when they go together along with the pulp pump.

- Q: How many degrees does the ceramic filter melt?

- You should say clearly what ceramic you useHowever, as a melting furnace or filter medium, alumina products are the most versatile, but also silicon carbide, corundum, mullite, spinel and so on. They use very high temperatures.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Selection of new ceramic filter plate:Because of the different size and characteristics of the pulp, different users need ceramic filter plates with different pore sizes (i.e., the average range of their surface pore size). In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- Whether the ore conditions are changed, such as pulp type, mud content, fineness, concentration, etc..

- Q: What is the reason that the whole ceramic filter does not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor. Other questions about ceramic filter, welcome to chat with me or look at my head

Send your message to us

Ceramic Filter Plate Alumina Grinding Ball with Higher Hardness and Density

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords