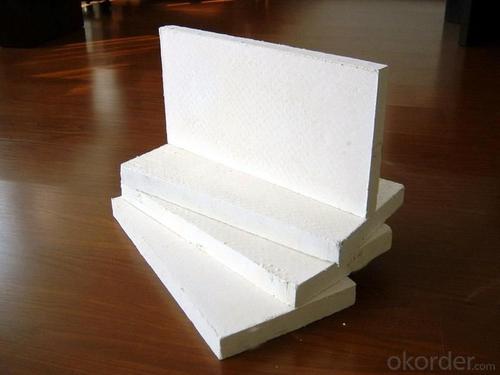

Ceramic Filter Plate Furnace Heat Insulation Ceramic Fiber Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic fiber boards are made from Jiuqiang refractory ceramic fiber, attending inorganic and suitable organic binders. The mixture is vacuum processed into boards or formed shapes that keep good mechanical strength after heating. These products can be manufactured using four basic fiber types: Sinoshine Board, classification temperature 1000°C,1150°C, 1260°C, 1400°C.

Features:

1.Low heat storage and low thermal conductivity;

2.High compression strength;

3.Non–fragile materials and good toughness;

4.Accurate dimension and good palneness;

5.Structure homogeneity and easy machining;

6.Easy to install

7.Continual production, even fiber with stable property;

8.Excellent heat stability and thermal shock resistance

Application:

.Cement building industry, kiln back lining-thermal insulation;

2.Ceramic industry-lining of various kilns for thermal insulation;

3.Petrochemical and metallurgy industries- back linings, wall linings, and linings-thremal insulation;

4. Glass kiln lining and back lining thermal insulation;

5.Heat treatment furnace kiln back lining thermal insulation;

6. Aluminium factories-reduction cell firebricks back linings;

7.High temperature reaction, heating device-wall lining and back linings

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- The ceramic filter plate by table and the distribution of a large number of porous capillary ceramic filter, when working in the water slurry channel is used so the microporous ceramic filter plate internal residual has a lot of water, such as low temperature, the inside of the frozen water volume will swell, causing damage to the ceramic the inside of the microporous filter plate structure.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- CleanThe cleaning of ceramic filter is divided into two parts: reverse flush cleaning (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board.Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure.Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.).

- Q: Can the plate filter press pass through the filter plate?

- Specific, it is necessary to choose the filter characteristics according to different materials. Plate and frame filter press: plate and frame filter press is an industrial realization of solid, liquid separation, plate and frame filter press is suspension, liquid-solid, liquid two phase, applied to chemical, ceramics, oil

- Q: The working principle of ceramic filter

- Based on the work principle of ceramic filter function of the capillary, by using porous ceramic as filter media, a large number of small capillary action with solid-liquid separation equipment design principle using microporous ceramic disc filter in negative pressure, working conditions, characteristics of the microporous ceramic filter plate with its unique water impermeable, extraction of ceramic filter plate and external vacuum cavity the differential pressure tank suspension material under the action of negative pressure adsorption in the ceramic filter plate, solid material can not through the microporous ceramic filter plate is retained on the surface of the ceramic plate, and the liquid due to the hydrophilic effect of vacuum pressure difference and the ceramic filter plate is passed into the gas-liquid distribution device (vacuum barrel) efflux or recycling so as to achieve the purpose of solid-liquid separation.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q: Common troubles of ceramic filter

- Ultrasonic cleaning, ceramic filter plate cleaning is not clean. The main reason is that the power box is faulty, the power supply is burned out, the line is aging, the energy head is burned out, the ultrasonic box is broken down, and the water level in the pulp tank is too low;

- Q: Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q: Does the ceramic factory use hydrochloric acid?

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: What is the reason that ceramic filter does not absorb mineral powder?

- There may be a failure of the filtrate pump, the diaphragm of the pump is damaged, and the mechanical seal of the pump is invalid

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter.

Send your message to us

Ceramic Filter Plate Furnace Heat Insulation Ceramic Fiber Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches