Ceiling Profile Lightgage Steel Joist Ceiling Grid Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

We are a manufacturer of steel keel with well-equipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in decoration and other industries.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Advantages and features:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

3.Image

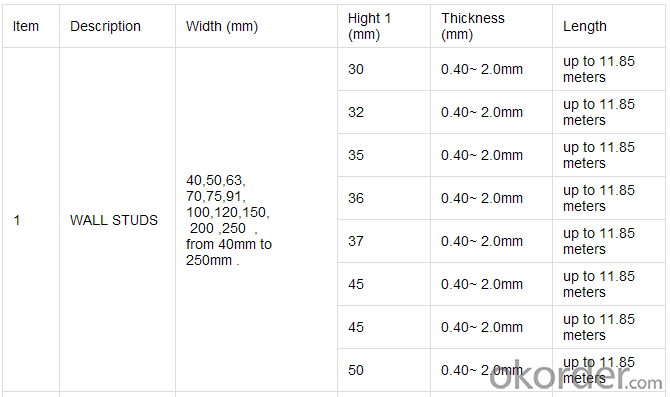

4.Detailed Specification

5.FAQ

functions

1. light weight, high intension, waterproof, earthquake-resistance, dustproof, sound isolation, sound absorption, constant temperature,etc.

2. short time construction peiod and convenient and simple construction.

Lightgage steel joist for ceiling system

1.Material:hot dip galvanized steel

2.Surface treatment: roll coated

3.Application: ceiling grid system

4.Zinc content: 60-140g per sq.m.

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- 5, the installation of sub-keel 1> has been played by a good sub-keel sub-line, card sub-keel hanging pendant. 2> hanging sub-keel: according to the provisions of the provisions of the keel spacing, the sub-keel hanging hanging on the main keel, the design requirements, the general spacing of 500mm-600mm. 3> When the length of the keel to be a number of continuation of a long time, with the keel connection, hanging in the keel at the same time the connection, straighten the fixed. ?Install the cover panel, the installation of the panel before the end of the terminal equipment must be located on the ground and the various pipeline inspection and acceptance, before allowing the installation of the panel. Cover plate and light steel keel fixed method is: Light steel keel skeleton after acceptance, began to install the first layer of cement fiberboard. First in accordance with the room space on the cement fiber board layout, layout is not allowed to appear below 100mm slats. After the completion of the version, according to the layout placed cement fiber board, and with self-tapping wire fixed firmly. Self-tapping screw spacing of 150-170mm. After the completion of the first layer of cement fiberboard, should check the flatness of the allowable error should be controlled within 3mm. The first layer of cement fiberboard after the acceptance of the installation has been compressed composite panels, the installation of the use of adhesive method, the installation of the first two sides and then the middle.

- Q: Will the light steel keel ceiling area is small can be no boom?

- But if there is no boom, then a long time there is danger, after all, the main force of the ceiling keel is the boom.

- Q: Toilet integrated ceiling with good or good light steel keel good

- Light steel keel is a high-quality continuous hot-dip galvanized strip as a raw material, the cold bending process from the building with metal skeleton. Fire, rust, anti-aging performance. Wood keel commonly known as the wooden side, mainly by the pine, linden wood, fir, imported drying planing and other wood processed into rectangular or square section of the wood. Easy to shape, easy to install nail sticks easy to install, especially suitable for connection with other wood products, the disadvantage is not moisture, easy to deformation, no fire,

- Q: Light steel keel ceiling and wall construction technology

- Material purchase requirements 1. Light steel skeleton sub-U-shaped skeleton and T-skeleton two, according to the load and not on the master. 2. Light steel skeleton main pieces for large, medium and small keel; accessories hanging pendant, connectors, hanging plug. 3. Spare parts: a boom. Flower blue screws. Nail. Self-tapping screws. 4. According to the design can choose a variety of cover panels. Aluminum pressure or plastic pressure every bar, the material varieties. Specifications. Quality should meet the design requirements. 5. Binder: should be selected according to the performance of the main material, before use for bonding test.

- Q: Light steel keel ceiling budget how to calculate

- According to the net area of the room, the light steel keel and the surface layer, if it is flat sets of a ceiling, if there are high and low sets of hanging ceiling, and can calculate the lamp openings and light boxes, of course, there are other art ceiling Construction requirements and quota related provisions apply to the fixed subhead. Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel. According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series.

- Q: Consultation: What is the keel of the living room ceiling?

- Light steel is not deformed, not damp, but no wood light and flexible shape. Light steel is relatively small density of steel, the quality of light hardness is large, is the ceiling of the main material, through the screw and the floor phase, used to fix the ceiling or objects. Is the home furnishings commonly used in the ceiling material. Wood keel commonly known as the wooden side, mainly by the pine, linden wood, fir and other trees processed into rectangular or square section of the wood. Cheap and easy construction is the biggest advantage of wood keel. However, flammable, easy to mold rotten. In order to prevent the wood keel burning can be painted on its surface fire retardant coating. Wood keel shape ceiling, can be used in the fire level to teach low engineering, the advantages of wood keel can do any complex shape, and wood products connected to the deformation coefficient to teach small. The disadvantage is that moisture is easily deformed, not fire, so it is not suitable for use in humid environments. Wood keel in the construction and installation, must be kept dry, reasonable spacing, brush fire anti-corrosion coating, generally used for home improvement small area of ??the ceiling shape, when the installation of the keel can be coated with anti-rust paint on the screws to prevent the rust. (Some modeling cumbersome American decoration, European decoration will use the wooden keel to do some complex modeling top)

- Q: Light steel keel second ceiling

- Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

- Q: Gypsum board ceiling side keel with a good side of the wood or supporting the light keel edge keel good?

- Work with wood keel is good, the quality is still supporting the light steel keel is good, at least not easy to deformation, not raw insects (fixed time when a few points)

- Q: Whether the ceiling light steel keel has the raw material inspection standard

- Ceiling light steel keel with raw material testing standards, ceiling light steel keel thickness requirements

- Q: The difference between light steel keel ceiling and macadam ceiling

- Do you mean light steel keel ceiling and wooden keel ceiling? Who used the big board to do the shelf ah ... ... Light steel keel Ye Hao, wood keel Ye Hao, after playing the shelf, have to use the big core board to do modeling, and then covered with a layer of gypsum board, directly directly with gypsum board to do modeling

Send your message to us

Ceiling Profile Lightgage Steel Joist Ceiling Grid Components

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords