Ceiling Profile Lamp Reflector Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Our company specializes in manufacturing metal forming equipments with over 10 years in business.

All of them sell well in home and abroad, and are widely used in building materials, chemicals, metallurgical industry, electric power, coal, food, machinery, etc. We have established good reputation of quality and after-sale service.

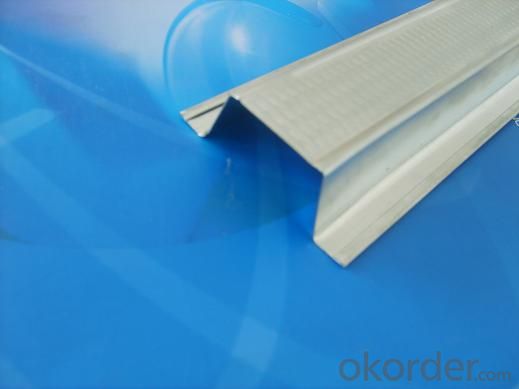

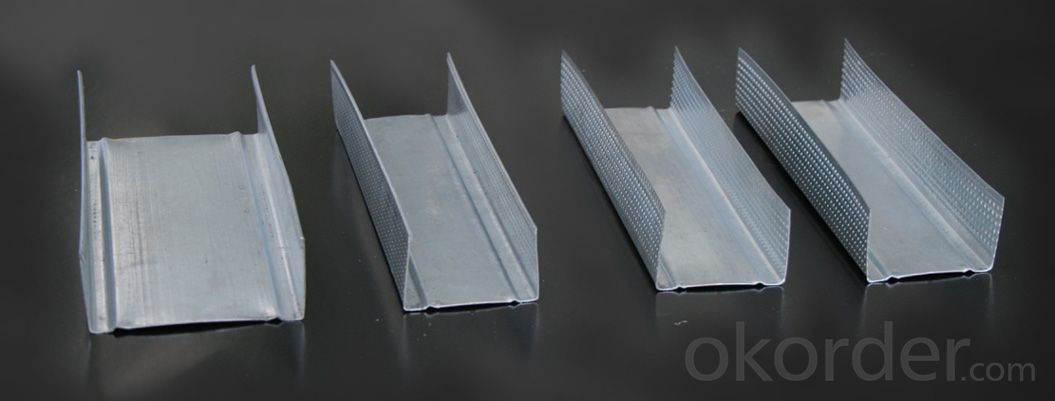

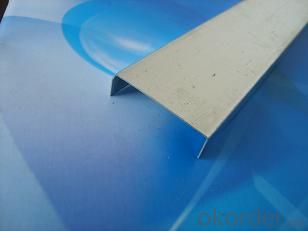

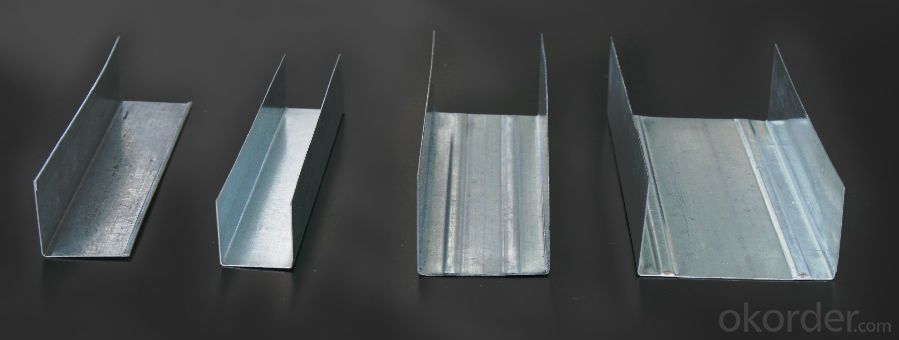

1.Type: Ceiling grid or drywall partition component

2.Thickness:0.4-1.2mm, size:42*25, 52*25, 72*25, 75*25, 100*34.5

3.Length: 2800mm, 3000mm, 3200mm

4.Light weight, high strength

5.Package:10pcs per bundle with plastic strip or iron wire

6.MOQ: 10 Tons, negotiable

7.Delivery time: T/T,

Feature and advantage

1)Rust proof

2)Corrosio-resistance

3)Multi-roll production technology

4)Fireproof, anti-seismic

5)Environmental friendly, Pls Be Assured Use

6)Easy installation, precisely dimensioned

3.Image

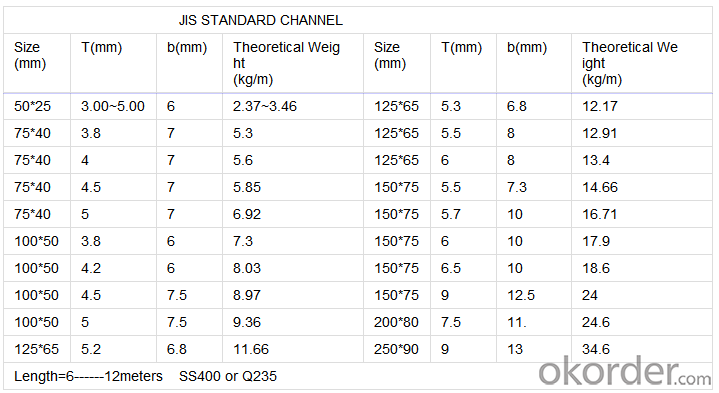

4.Detailed Specification

5.FAQ

Dry wall system install

1.To fix the ceiling track and the floor track to the clear ceiling and the clear floor with the shoot-nails.

2.Install the metal stud to the ceiling track and the floor track, and use the rivets to fix them in accordance with the design space.

3.The gypsum boards should be installed to the frame with the tapping screw, when the whole frame is formed .

4.One-layer gypsum board is used , the space between two gypsum plaster boards should be staggered. And the double-gypsum board is used the space between two gypsum plaster boards should also be staggered.

5.Joint putty process the final decoration can be done.

- Q: Wood keel expensive or light steel keel expensive?

- Hello there! Wood keel with light steel keel which expensive? There are two possibilities, if the material by material to measure the two materials, it is light steel keel expensive. If used in the project of the ceiling, in accordance with the standard construction process construction, that light steel keel cost will be cheaper.

- Q: Light steel keel gypsum board ceiling need floor?

- Owners have money to do the second floor

- Q: What kind of thickness of the light steel keel there is no specification?

- Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on.

- Q: Is the thickness of the light steel keel related to the height of the ceiling?

- Light steel keel selection with the weight of the ceiling, rather than height.

- Q: Light steel keel gypsum board ceiling is good, or sauna board, integrated ceiling buckle board good?

- Will not fall off the light steel keel qualified acceptance criteria is able to hang a person in general home, then people will not fall off the brush on the latex paint can be the color can brush

- Q: Will the use of light steel keel and gypsum board ceiling decoration home ceiling, how much money ah?

- Flat top artificial materials 55 yuan a square, the opposite sex 75 to 80 yuan a square

- Q: Ceiling light steel keel 50/60 in 60 on behalf of what

- 60 represents the width of the main and vice keel,

- Q: PVC plastic buckle plate ceiling with what keel ah?

- There may be putty or gypsum did not dry on the latex paint

- Q: Gypsum board ceiling side keel with a good side of the wood or supporting the light keel edge keel good?

- The edge of the wood keel good

- Q: Home decoration living room ceiling (light steel keel or wood keel) between the two, what is the difference?

- Family wood keel more convenient, light steel keel is mainly used in large space ceiling -

Send your message to us

Ceiling Profile Lamp Reflector Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords