Eco-Friendly Ceiling Profile Lightgage Steel Joist 75Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Specifications

Used for wall partition

High intensity and toughness

Easy installation

1)Size:

QC 75×45×0.6

QC 75×45×0.7

QC 75×45×0.8

QC 75×45×1.0

2)Features:

(A)light-weight, long lifetime, high durability and rust resistance.

(B)Easy be cut apart, convenience in stallation, environment friendly.

3) Application:

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

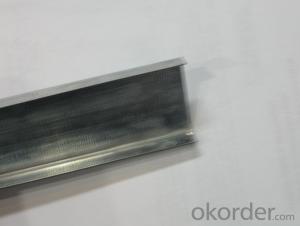

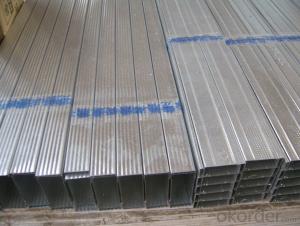

3.Image

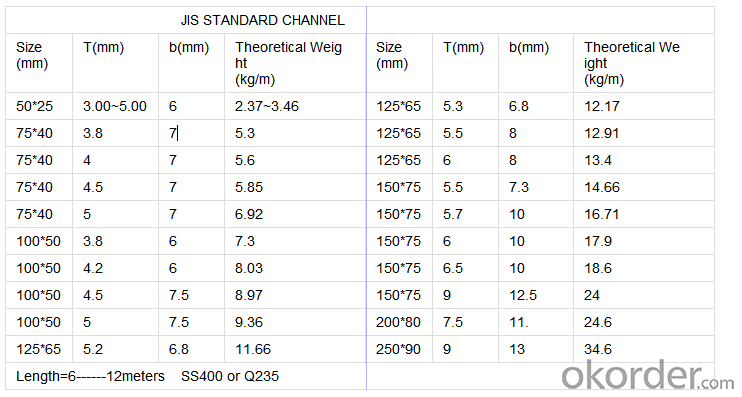

4.Detailed Specification

5.FAQ

Fundamental functions of cold roll forming machine

The adjustable and speed changeable equipment is used to roll various kinds of profile materials. It uses decelerator to transmit each gear case in the main machine. The upper and lower two universal rotational axes on each channel drive each roller in arch frame to roll shaping. The number of forming lines is decided on the demand of sectional design or clients'. The line is equipped with automatic feeder and guide feeder. Adopting hydraulic pressure or pneumatic to realize automatic tracking cutting and unloading. It also adopted arbitrarily scale structural section of material receiving station and electric control system with synchronized movement.

Above-mentioned is our factory’s cold roll forming machine which has been manufactured. In this field, our factory has accumulated a great quality of equipments and mould materials. In no exceptional circumstances, our company can give you one package service including comprehensive technology, quality assurance, and reasonable price, finishing designing, creating, debugging and after-sale service. We are willing to deliberative discuss and cooperate with you about the exploitation of the varieties of profile steel. We are earnestly welcome you to our factory to have a field trip, we can offer you all kinds of product introduction and equipments technical reference.

Thickness: 0.15mm - 4.00mm

coil Width: 11mm-1500mm

Zinc coating: Z80 - Z275/m2

CID: 508 or 610mm

Standard: EN, JIS, GB

Grade: DX51D, SGCC, Cs-B, S280, S320, S350, S380, DQ, DDQ, Q195

Skinpassed: If required

Surface processing: Regular spangle, Minimized spangle, Zero spangle, bright spangle

Surface chemical processing: Chromate, un-chromate passivation and fingerprint resistant treatment;

slight oiled or non-oiled

- Q: Will the light steel keel ceiling area is small can be no boom?

- But if there is no boom, then a long time there is danger, after all, the main force of the ceiling keel is the boom.

- Q: Light steel keel gypsum board ceiling, the main bone the most side of a row, that is, the nearest row from the wall, and the spacing between the walls of what is the rule, if not, is not also by the distance between the main bone 900 -1200MM, gypsum board fixed on the side of the keel on the line. What are the rules for the keel?

- If you use the gypsum board is 600 × 600 specifications, the wall with a glue stick a corner, the main bone spacing is 600MM.

- Q: Light steel keel will rust?

- Buy the difference between the big ah, that is the difference between the grandfather, such as the United States is the United States is such a marketing before entering China? Shame lost to the United States, not only lost the face of the Chinese people, but also tarnished the Americans Finally paid the brand to pay the full amount, then pay the face, and only buy this brand of ink to know.

- Q: Construction works: light steel keel partition in a ceiling ceiling, the height should be calculated to the ceiling ceiling or calculated to the bottom of the concrete floor?

- When calculating the area of the ceiling, the cross section of the light steel keel shall be reduced.

- Q: Why the ceiling keel

- 1, modeling should use the ceiling keel, only to facilitate the fixed gypsum board, carved panels, panels and other materials 2, can be directly used wood board primer, which is only suitable for small area ceiling keel, it acts as a keel role. Expansion: home use generally use wooden keel, tooling or large-scale ceiling is required to use light steel keel.

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The effect of the two ceiling is the same, but the material is different, light steel keel price is relatively cheap, the best light steel keel material with accessories per square price of not more than 15 yuan, detailed specifications, the unit price is as follows: 1.0 main keel each Square 2 5,0.5 pairs of keel 8 per square, boom diameter 8MM 1 2, accessories 2 per square, loss plus a little on the line This ratio is limited to flat top, and only to the building materials market, light steel keel store to have such a price Oh, the decoration company fucking offer to turn several times, not just a little bit high, be careful slaughtered. Gypsum board made of the dragon card is good, imported brands are Lafarge, Jieke, can be resistant, more than 20 dollars a count down every square as long as 10 less than How can it be professional? The The

- Q: Master ceiling should choose what specifications of light steel keel

- Your phone number to me! So hard to say

- Q: Now home decoration, the original ceiling with light steel keel. Now began to install, decoration company said light steel keel will be relatively thick, there will be a sense of oppression, to be replaced by wood keel. Will you heroes this is based on it?

- You did not specify your home that the ceiling is the number of "thickness" - should be said that the upper and lower height, here can only tell you, light steel keel ceiling minimum height of 15 cm. That is, if the bottom of the ceiling, to the bottom of the floor between the distance of 15 cm or more, do light steel keel ceiling is possible. Your home that the ceiling should not be 15 cm are not it? With light steel keel to do the ceiling, compared with the use of wood keel to do, relatively more trouble, because the small size, coupled with the possibility of modeling and other reasons, the decoration company may be reluctant to use it. However, the use of light steel keel to do the ceiling, in the prevention of deformation of the ceiling, gypsum board surface cracking, etc., than the wooden keel to do the ceiling is much better. So, if the distance is no problem, ask them to use light steel keel to do the ceiling as well

- Q: Light steel keel ceiling budget how to calculate

- Hanger Light steel keel material accounting A ceiling Verification according to the construction plan on the ceiling structure and size, respectively, the calculation of each indoor ceiling of the main keel and vice keel number, and then the chamber The total number of primary and secondary keels required to add the total number of M. Taking into account the size of the construction specifications and the actual size of the difference, as well as the construction of the truncation loss and other factors, the need to add the total 3% margin, so that can be practical The total number of M required is in meters (m). The empirical formula is: M total = 1.03M Note that the total number of primary and secondary keel should be calculated separately, such as the main and vice keel of the same material, you can also be calculated.

- Q: Do you need to leave a gap between the ceiling and the wall? If you need to stay much in line with design requirements? Need to do those deals

- Each gypsum board should be left half a centimeter (5 mm) sewn this is the construction request. Prevent cracks

Send your message to us

Eco-Friendly Ceiling Profile Lightgage Steel Joist 75Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords