Gypsum Board Wall partition/metal stud and track corner bead

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Gypsum Board Wall partition/metal stud and track corner bead

Instruction

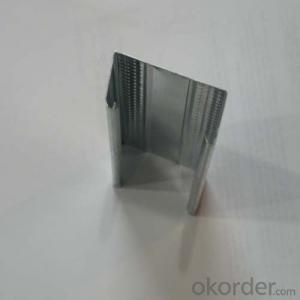

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe,

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Gypsum Board Wall partition/metal stud and track corner bead

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

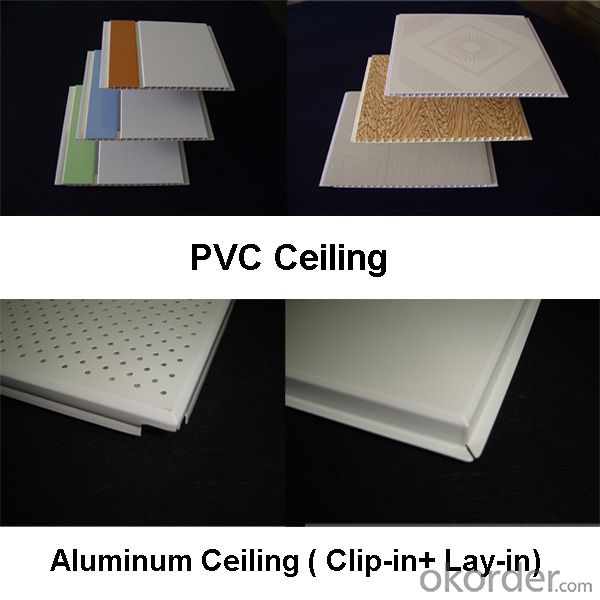

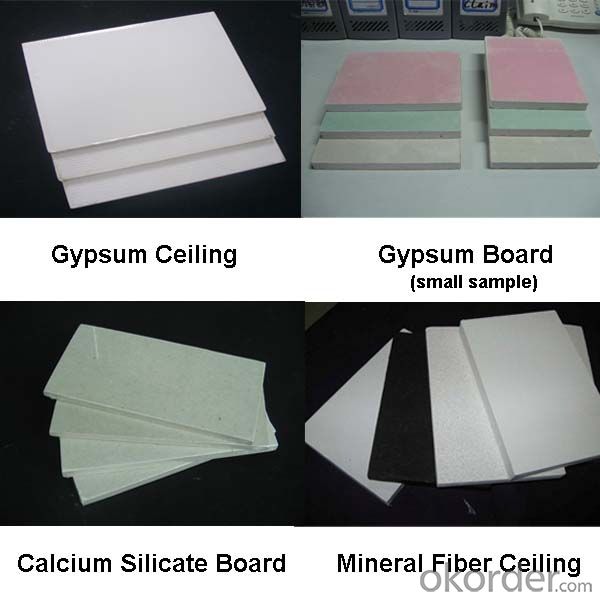

Other products we supply:

Gypsum Board Wall partition/metal stud and track corner bead

- Q: Light steel keel gypsum board modeling ceiling

- According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series.

- Q: What kind of thickness of the light steel keel there is no specification?

- Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on.

- Q: Master ceiling should choose what specifications of light steel keel

- Your phone number to me! So hard to say

- Q: Light steel keel ceiling and wood keel ceiling What is the difference between ah! Which performance is better, the price difference is different! Ask everyone!

- Home decoration on the process requirements are higher.With the wooden keel to make the framework easy to correct .. so that the ceiling is not easy to deformation in the installation, after all, is the wood due to changes in the weather season, there will be hot up cold shrinkage. When the decoration is generally required for the wooden keel frame fixed. Fixed in the ceiling keel should be every 60 cm should play an expansion screw. The next well-shaped frame should be bayonet handle, gun nail fixed. Well shape frame every 30 cm The wood keel is a flammable material, no fire .. at the price of wood keel than light steel keel is higher .. now wood keel one meter at least 2 yuan. , Light steel keel need to be placed side by side .. Light steel keel because the specifications are too long, not suitable for use in the family, because the home decoration is not like a tooling decoration ceiling is a large area with light steel keel is drawn, The family can not draw, but also a reason is the family ceiling because the area is only part of the use of light steel keel is not to do. Must be the wooden keel frame can be .. so in the home decoration with wood keel is the best choice.

- Q: Light steel keel gypsum board ceiling is good, or sauna board, integrated ceiling buckle board good?

- Half with gypsum board can now use light steel keel gypsum board ceiling more

- Q: The difference between light steel keel ceiling and macadam ceiling

- The former light weight, you can easily hang a variety of modeling top, which is estimated that no advantage, weight heavier, install trouble, etc.!

- Q: Play light steel keel cut off how not to damage the ceiling

- If the existing ceiling is gypsum board, there must be keel in the top

- Q: Now decoration light steel keel 600X600 mineral wool board (ordinary) ceiling how much money a square meter?

- Different regions, the material is more than 20 yuan a square, construction costs 20 yuan a square,

- Q: Ceiling with light steel keel size is generally how much

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm.

- Q: Which is more cost-effective, want to get a professional answer Oh, anxious decoration it

- The kind of keel is determined by the material of the ceiling. Light steel keel for, gypsum board, integrated ceiling, relief gypsum board mineral wool board (both bones for the paint). Kitchen and other basic not suitable, integrated ceiling can be. If only the ordinary buckle top, it must be wood keel, or can not be fixed pinch. On the issue of cost-effective, light steel keel and wood keel basically no comparable, the same area of the former price of the latter twice as much as the latter, but iron is better than wood. Home improvement basically no light steel keel, because the kitchen is not suitable, in the living room after the ceiling height than the keel to 10 cm lower.

Send your message to us

Gypsum Board Wall partition/metal stud and track corner bead

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords