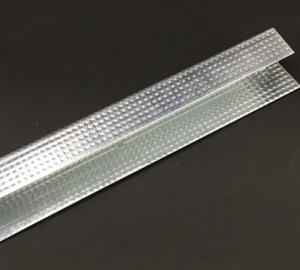

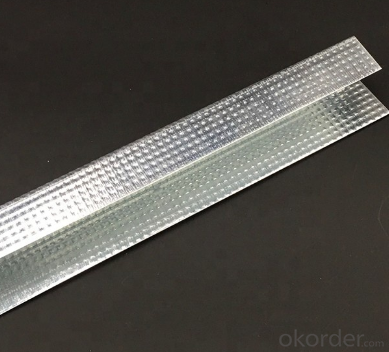

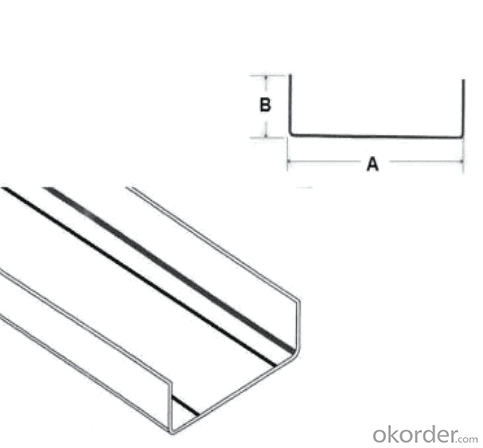

Ceiling Profile Steel Profiles for Ceiling and Partition System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Profile for Ceiling and Partition System

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

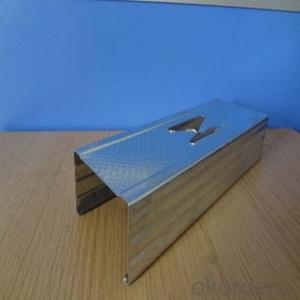

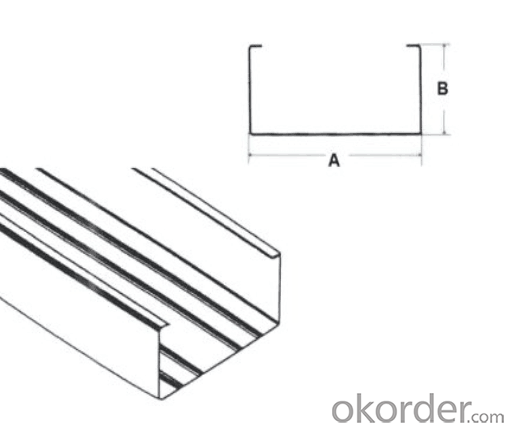

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: Is in accordance with the vice keel 400, the main dragon spacing 600 spacing arrangement?

- Light steel keel ceiling 400 * 600 meaning: the main keel and the distance between the main keel 600MM, vice keel and vice keel spacing of 400MM. Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel. According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series. Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on.

- Q: Light steel keel ceiling and wood keel ceiling What is the difference between ah! Which performance is better, the price difference is different! Ask everyone!

- Home decoration on the process requirements are higher.With the wooden keel to make the framework easy to correct .. so that the ceiling is not easy to deformation in the installation, after all, is the wood due to changes in the weather season, there will be hot up cold shrinkage. When the decoration is generally required for the wooden keel frame fixed. Fixed in the ceiling keel should be every 60 cm should play an expansion screw. The next well-shaped frame should be bayonet handle, gun nail fixed. Well shape frame every 30 cm The wood keel is a flammable material, no fire .. at the price of wood keel than light steel keel is higher .. now wood keel one meter at least 2 yuan. , Light steel keel need to be placed side by side .. Light steel keel because the specifications are too long, not suitable for use in the family, because the home decoration is not like a tooling decoration ceiling is a large area with light steel keel is drawn, The family can not draw, but also a reason is the family ceiling because the area is only part of the use of light steel keel is not to do. Must be the wooden keel frame can be .. so in the home decoration with wood keel is the best choice.

- Q: Light steel keel ceiling effect is what

- Light steel keel wall ceiling general fire can be over. And cheap, with the use of peace of mind. Compared with the wooden keel ceiling, the main advantage is fire, such as ktv, bars and other public places with much more.

- Q: Light steel keel ceiling budget how to calculate

- Hanger Light steel keel material accounting A ceiling Verification according to the construction plan on the ceiling structure and size, respectively, the calculation of each indoor ceiling of the main keel and vice keel number, and then the chamber The total number of primary and secondary keels required to add the total number of M. Taking into account the size of the construction specifications and the actual size of the difference, as well as the construction of the truncation loss and other factors, the need to add the total 3% margin, so that can be practical The total number of M required is in meters (m). The empirical formula is: M total = 1.03M Note that the total number of primary and secondary keel should be calculated separately, such as the main and vice keel of the same material, you can also be calculated.

- Q: Light steel keel ceiling need to pay attention to what issues?

- 1, ceiling uneven: small keel installed when the elevation is not allowed. Construction should pull the line, so that through the long keel by arch requirements, so that the elevation of accurate location. 2, wooden skeleton firm is not strong: large keel and hanging connection method, keel nail method should meet the design and construction requirements. 3, cover slab block gap is not straight, wide and inconsistent, construction should pay attention to plate specifications, block size, the installation location is correct. 4, pressure section, the pressure side is not tight, not straight: the construction should be the position of the line, cover the stone joints should be straight, pressure and sliver slate close to dense.

- Q: Do steel keel ceiling, need to use white latex?

- If the ceiling with light steel keel, then white latex is used to stick gypsum board between the suture, not add putty but kraft paper Kazakhstan.

- Q: Light steel keel ceilings are the main keel specifications is how much

- Works of the gypsum board of 50 and 60 are both. Mineral wool ceiling 38 can be.

- Q: 60 series light steel keel ceiling specifications

- 50,60 series is divided according to the width of the main keel.

- Q: Light steel keel gypsum board ceiling artificial materials about how much money a square meter

- Light steel keel ceiling material costs about 40. Keel 'gypsum board GB and non-standard price gap, depending on your choice. Labor costs flat about 35, modeling top 50-60 a square, depending on the specific complexity.

- Q: Do you need to leave a gap between the ceiling and the wall? If you need to stay much in line with design requirements? Need to do those deals

- Each gypsum board should be left half a centimeter (5 mm) sewn this is the construction request. Prevent cracks

Send your message to us

Ceiling Profile Steel Profiles for Ceiling and Partition System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords