Ceiling Profile Partition Walls Steel Channel/C Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Lightgage Steel Joist

1.according to standard of GB/T11981-2001

2.adopting advanced domestic equipment

3.modern technique

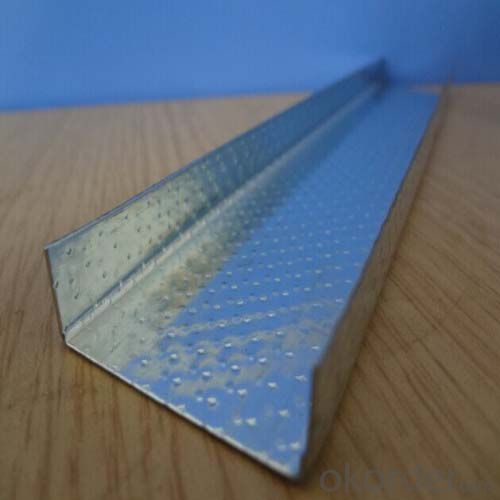

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

3.Image

4.Detailed Specification

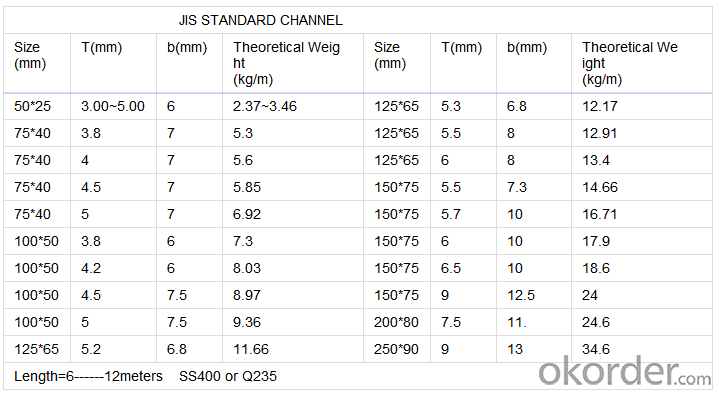

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

5.FAQ

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

9. slit edge or mill edge.

10. Any third party inspection can accept.

- Q: Light steel keel ceiling The first main keel distance from the wall should be how much? To be specific.

- Under normal circumstances about 30cm on it.

- Q: Construction works: light steel keel partition in a ceiling ceiling, the height should be calculated to the ceiling ceiling or calculated to the bottom of the concrete floor?

- Light steel keel wall is to rely on the ground and the floor at the end of the two connections to maintain stability, since the keel has been received at the end of the floor, of course, is calculated to the bottom of the floor rather than the top of the ceiling.

- Q: Light steel keel ceiling calculation method

- Let the decoration of the people estimate, and then you go to buy.

- Q: Light steel keel ceiling good or wood keel good? Residential. I want to use light steel keel, but the designer said the reasons for modeling, light steel

- Now the basic use of keel less we do are to use light keel to do

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The effect of the two ceiling is the same, but the material is different, light steel keel price is relatively cheap, the best light steel keel material with accessories per square price of not more than 15 yuan, detailed specifications, the unit price is as follows: 1.0 main keel each Square 2 5,0.5 pairs of keel 8 per square, boom diameter 8MM 1 2, accessories 2 per square, loss plus a little on the line This ratio is limited to flat top, and only to the building materials market, light steel keel store to have such a price Oh, the decoration company fucking offer to turn several times, not just a little bit high, be careful slaughtered. Gypsum board made of the dragon card is good, imported brands are Lafarge, Jieke, can be resistant, more than 20 dollars a count down every square as long as 10 less than How can it be professional? The The

- Q: Ceiling light steel keel specifications are models which several

- Light steel keel is divided into wall keel (Q) and ceiling keel (D) two categories

- Q: Light steel keel ceiling budget how to calculate

- According to the net area of the room, the light steel keel and the surface layer, if it is flat sets of a ceiling, if there are high and low sets of hanging ceiling, and can calculate the lamp openings and light boxes, of course, there are other art ceiling Construction requirements and quota related provisions apply to the fixed subhead

- Q: Consultation: What is the keel of the living room ceiling?

- Light steel is not deformed, not damp, but no wood light and flexible shape. Light steel is relatively small density of steel, the quality of light hardness is large, is the ceiling of the main material, through the screw and the floor phase, used to fix the ceiling or objects. Is the home furnishings commonly used in the ceiling material. Wood keel commonly known as the wooden side, mainly by the pine, linden wood, fir and other trees processed into rectangular or square section of the wood. Cheap and easy construction is the biggest advantage of wood keel. However, flammable, easy to mold rotten. In order to prevent the wood keel burning can be painted on its surface fire retardant coating. Wood keel shape ceiling, can be used in the fire level to teach low engineering, the advantages of wood keel can do any complex shape, and wood products connected to the deformation coefficient to teach small. The disadvantage is that moisture is easily deformed, not fire, so it is not suitable for use in humid environments. Wood keel in the construction and installation, must be kept dry, reasonable spacing, brush fire anti-corrosion coating, generally used for home improvement small area of ??the ceiling shape, when the installation of the keel can be coated with anti-rust paint on the screws to prevent the rust. (Some modeling cumbersome American decoration, European decoration will use the wooden keel to do some complex modeling top)

- Q: PVC plastic buckle plate ceiling with what keel ah?

- Plastic buckle, it should be wooden keel, is the wooden side. If it is aluminum buckle, it should be light steel keel.

- Q: Light steel keel ceilings are the main keel specifications is how much

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm.

Send your message to us

Ceiling Profile Partition Walls Steel Channel/C Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords