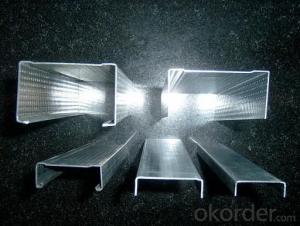

Ceiling Profile Metal Steel Profile Channel for Drywall and Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Metal Steel Profile Channel For Drywall for Gypsum Board

Instruction

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

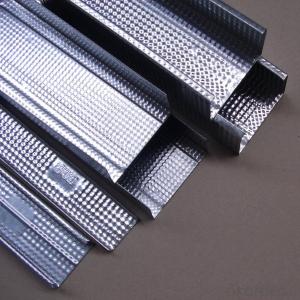

Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe,

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Metal Steel Profile Channel For Drywall for Gypsum Board

Advantages and features:

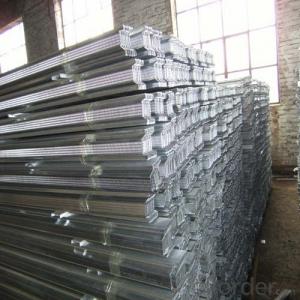

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

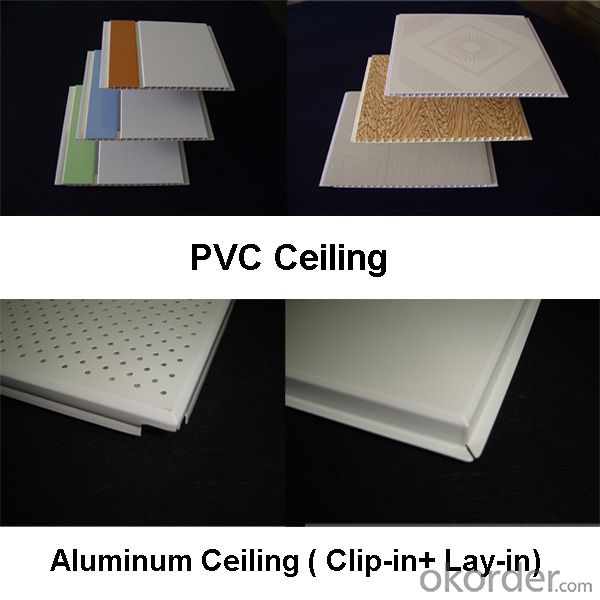

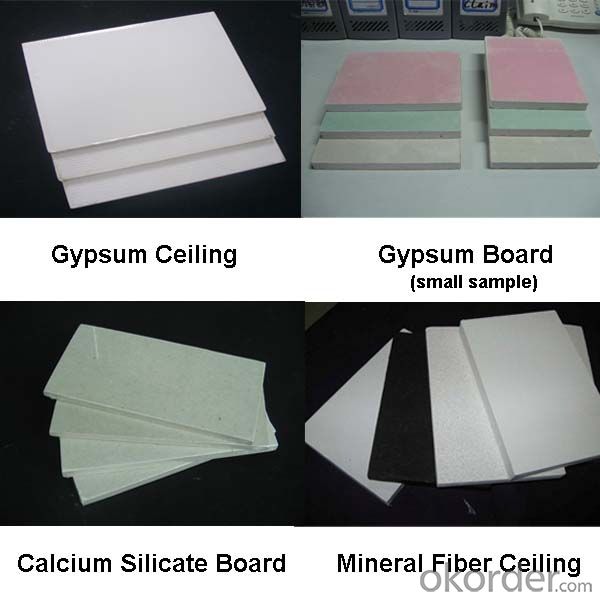

Other products we supply:

Metal Steel Profile Channel For Drywall for Gypsum Board

- Q: Light steel keel ceiling which brand is better

- Domestic dragon card can, foreign brands have Lafarge, Jieke is also good. Above, not advertising, on the matter only - the landlord itself is to do building materials, should not know it?

- Q: Decoration light steel keel ceiling in the side of the keel main keel vice keel What is the meaning?

- The side keel is used for fixing to the wall, with the keel connected with the keel, the main keel connected to the pole to connect the vice keel.

- Q: Divided u-type light steel keel in the ceiling spacing of less than 2 meters, 2.5 meters or less, according to the large keel count spacing, or by the small keel count spacing.

- Vice keel (should be the little keel you said) and the distance between the vice keel of 30cm, gypsum board thickness of 9.5mm. If the thickness of the gypsum board is 12mm, the distance between the vice keel can be enlarged to 40cm. But in the actual construction, the vice keel spacing is 30cm, basically no one made 40cm.

- Q: Light steel keel ceiling one square meter how much money

- Ordinary flat ceiling artificial 25 yuan / m2 or so, light steel keel + gypsum board material about 25 to 28 yuan / m2 or so

- Q: Now home decoration, the original ceiling with light steel keel. Now began to install, decoration company said light steel keel will be relatively thick, there will be a sense of oppression, to be replaced by wood keel. Will you heroes this is based on it?

- You did not specify your home that the ceiling is the number of "thickness" - should be said that the upper and lower height, here can only tell you, light steel keel ceiling minimum height of 15 cm. That is, if the bottom of the ceiling, to the bottom of the floor between the distance of 15 cm or more, do light steel keel ceiling is possible. Your home that the ceiling should not be 15 cm are not it? With light steel keel to do the ceiling, compared with the use of wood keel to do, relatively more trouble, because the small size, coupled with the possibility of modeling and other reasons, the decoration company may be reluctant to use it. However, the use of light steel keel to do the ceiling, in the prevention of deformation of the ceiling, gypsum board surface cracking, etc., than the wooden keel to do the ceiling is much better. So, if the distance is no problem, ask them to use light steel keel to do the ceiling as well

- Q: Light steel keel specifications

- Simply talk to you about the connection between the keels: the boom with a bolt bolts fixed on the floor, with T-type keel hanging pieces connected T-shaped main keel, T-keel for long, in its interface with T-keel connections fixed, between the keel and the main keel is connected between the plug, you can not accessories. If the ceiling has an additional load or a large area of the ceiling, you need U-bearing keel, that is, after the installation of the boom, first with U-shaped keel (main keel) hanging pieces will U-shaped main keel and boom connection, T-type keel pendant will T-shaped longitudinal keel and U-shaped main keel connection

- Q: Ceiling 3 meters long light steel keel how much money one

- Hanging dragon keel points several kinds, and what kind of friends do you need it? Bearing type or non-bearing type, modeling or non-shape? We are the manufacturer of OKorder light steel keel, non-bearing heavy-duty ceiling keel We have 38 main keel and 50 main keel, 38 main keel GB is 2.7 yuan / m, 50 main keel GB is 4.32 yuan / m, bearing heavy ceiling We have 60 main keel, GB is 6.08 yuan / m, welcome to my space exchange Oh!

- Q: PVC plastic buckle plate ceiling with what keel ah?

- There may be putty or gypsum did not dry on the latex paint

- Q: Light steel keel gypsum board ceiling hanging cut short can be connected to you

- Yes, there is a dedicated takeover. Both sides have reed.

- Q: Do you need to leave a gap between the ceiling and the wall? If you need to stay much in line with design requirements? Need to do those deals

- Leaving 5 mm of the seam in the paste gypsum line on OK

Send your message to us

Ceiling Profile Metal Steel Profile Channel for Drywall and Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches