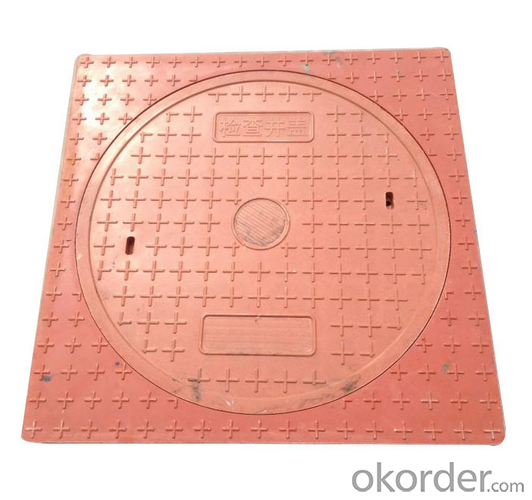

Casting Ductile Iron Manhole Covers C250 for Mining with Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| RGC-01L | C250 | 390*325 | 530*465 |

Advantages

· Higher quality /higher tensile

· Higher security /long life

· Possibilities of new locking systems

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.How do we start our cooperation?

If you are wholesaler, please send us the detailed information of the products you are doing, like Cover size, clear opening size, loading Grade, we will give you our best advices. We can start from sample order.

Sometimes if meet the size we don’t have, the new mould with your size and design can be considered from us. Let's talk more details about the New Mould and Charges. Then start our Cooperation.

- Q: What's the effect of casting copper?

- In general cast iron, the mass fraction of copper below 3% - 3.5% can increase the hardness; but when the cast iron has a tendency to chill, or when there is a hard point of free carbides, the addition of copper decreases the hardness.Copper can be used to improve the wear resistance, abrasion resistance, and shock absorption of cast iron, so it is often used in the manufacture of sliding friction iron castings, such as drilling machine spindle, automobile and tractor, valve tappet, etc.. But in white cast iron or chilled cast iron, adding copper does not make any improvement in its abrasion resistance.Copper for certain heat resistant cast iron and austenitic cast iron can increase the heat resistance and corrosion resistance, copper - chromium composite alloy to prevent oxidation under high temperature in the atmosphere from the skin effect is particularly effective, heat resistance and corrosion resistance of austenitic cast iron containing many mass fraction of 4% ~ 7% copper.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- Corundum sand: the main mineral composition is corundum alpha -Al2O3, used for investment casting, ceramic mold casting shell materials. The olivine sand: the main mineral composition of olivine (MgFe) 2SiO4, used in cast iron, non-ferrous alloy castings and high manganese steel casting molding sand and the core sand. Silica resources in nature resources, but suitable for casting with high SiO2 content of natural silica sand is not too much. Since 1951, China has carried out a general survey of the casting sand resources in the territory, but mainly limited to the main traffic lines and major industrial cities. Survey results show that Chinese can be used for natural silica sand casting is very rich in resources, a wide range of distribution. Inner Mongolia Zhelimumeng, natural silica sand reserves amounted to hundreds of millions of tons, the particle shape close to the circular, the content of SiO2 is about 90%. Fujian, Jinjiang Dongshan sea sand, the content of SiO2 is 94 to 98%, with a low volume of mud, are good natural silica sand. Are Duchang, Yongxiu Jiangxi County Xingzi, a large number of Quaternary lacustrine deposition of silica sand, the content of SiO2 is about 90%, low iron content, alkaline oxide less, uniform size, is a good lake sand. Guangzhou, Hunan and other places have abundant easily broken weathered sandstone, processing artificial silica sand, the content of SiO2 in more than 96%, can be used for the production of steel castings. Jiangsu Nanjing red sand, sandy mud pure, moderate, strong permeability, good viscosity, high silica content, less water, fine particles, pulls out the casting is smooth, stable quality, can be made of cast iron and non-ferrous metal parts of the sand and core sand

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Vacuum casting is the process of using ventilation molds. Molten metal flows into the mold by air pressure, and then removes air to form a vacuum. The casting process is mainly used for small parts or jewelry with exquisite detailsCompared with the traditional clay sand casting, heat hardening resin sand casting production with low surface roughness, high precision, good quality characteristics, dimensional accuracy of resin sand mold after hardening with good rigidity and high, and not easy to deform, so in the choice of process parameters, mechanical processing you can select a smaller margin, thereby reducing the consumption of metal solution and machining cost, which can improve the dimensional accuracy of castings.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- Processing stainless steel materials, you can use YG class tools, such as YG8, YG8N. The tool geometric parameters g0=15 degrees to 18 degrees, a0=6 degrees to 8 degrees, kr=75 degrees, ls=-5 degrees to -8 degrees; cutting amount is Vc=43 m/min, ap=0.3 to 0.5 mm, f=0.16mm/r.

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

Send your message to us

Casting Ductile Iron Manhole Covers C250 for Mining with Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords