Ductile Iron Manhole Cover C250

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 18 Tons m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

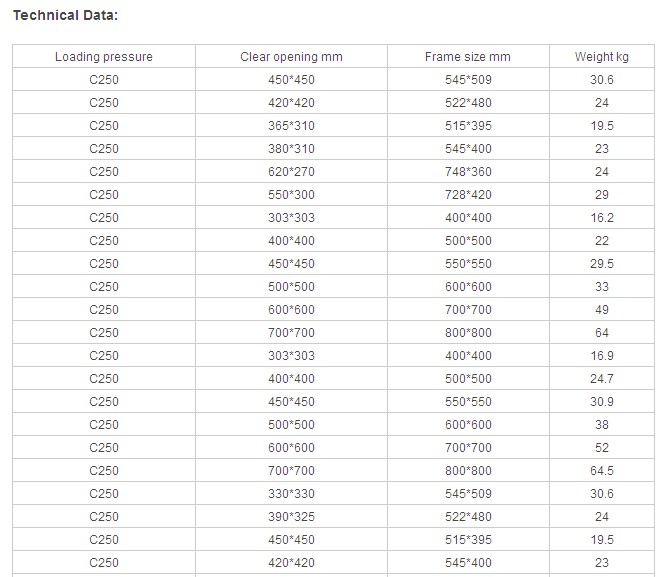

Manhole Cover Class C250

We manufacture top quality Manhole Cover made from cast iron, cast steel and stainless steel. We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers and gully grating in China with total annual capacity 50,000 MT. We are identified as one of the celebrated Manhole Cover Suppliers in China.

Class C250 (group 3 according to EN124)

The access covers and grates of this class are capable of withstanding a 250kN (~25 tonnes) test load.

Usage of Ductile Iron Manhole Cover C250 :

Pedestrians, Pedal Cyclists

Features of Ductile Iron Manhole Cover C250 :

1. High load rating and strength

v Similar hard property as cast iron, while have a overwhelming advantage on stretch recovery.

v Less noise and lower vibration transmissions.

2. Against theft and safety options

v Zero theft value, reducing potential accident and further maintenance cost caused by thieves.

v Surface anti-slip thread guarantees safe road condition even in extreme weather.

v Locks are available as an option molded into the cover to improve security rate.

v Non-electricity conduction and non-heat conduction.

3. Lightweight

v Compared with cast iron manhole covers, composited covers are 50% lighter.

v Lightweight allows more loading per vehicle, more convenient transportation and economical saving.

v Allows a safer working condition, which a SINGLE worker is enough when installation without risk of injury.

4. Durable service life.

v More than 30 years service life without crack and color fading, comparing to 5 years of cast iron.

v Anti corrosion,water, dust and pets tight, well sealed prevent poisonous gas leaking out.

v Without displacement, freely radio signal passing.

v Higher and lower temperature tolerance with the range -40°C-200°C.

v Wear indicators available when thread depth is in a danger value.

5. Free design

v Much more clear resolution ratio of surface design than cast iron or BMC.

6. Carbon footprint saving and environmental care.

v Lower embedded energy carbon emission and during manufacturing process than cast iron covers.

Packaging of Ductile Iron Manhole Cover C250:

Metal band, plastic, wooden pallet

Delivery Detail of Ductile Iron Manhole Cover C250 :

15 days after receiving the deposit.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 4, the performance requirements of the steel: whether castings or welding parts, there may be quality defects, but the casting will generally be worse than the weldment.You should be able to make a choice in the end.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- As a pig iron smelting, iron smelting belongs to physical, two belongs to the chemical refining, smelting, smelting generally not as a product after use, the product can be used as a chemical composition and casting the two refining, in general is to scrap as additional material after melting making products; engine castings have professional manufacturers making castings. You can own professional production of engine castings.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: How can the casting be quenched and tempered?

- Return, general castings (especially steel castings) commonly used heat treatment process is normalized and tempered. Of course there are completely by annealing or remove stress annealing...

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 1.5 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 60% |

| No.of Employees in Trade Department | 300 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 15,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Manhole Cover C250

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 18 Tons m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords