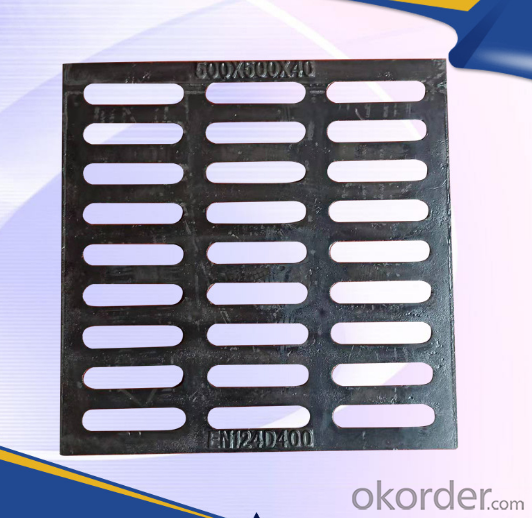

Casted Ductile Iron Manhole Cover C250 for Mining with Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| RGC-01L | C250 | 390*325 | 530*465 | 100 | 23 |

1.Standard:ISO9001,EN124

2.Applicable medium:gases,liquids,steam

3.Materail:ductile iron,Gray cast iron

Tested item standad

Tensile strength (Mpa)>10

Compressive strength (Mpa)>30

Modulus of elasticity(kg/cm2)>1.4*104

Cold-hot resistance measure<0.4< span="">

Water-absorption<1.0< span="">

Surface treatment

Black bitumen coated and hot gavanized

Advantages

Good compressive, waterproof,anti-rust ,bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% or so lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

- Q: What's the effect of casting copper?

- Riga. Copper is copper components, promote the graphitization of the copper element, make dense tissue, and to refine and improve the uniform distribution of graphite, which can reduce the chilling tendency of the cast iron, but also can promote the formation of pearlite, has a favorable effect on the section sensitivity. Copper has the tendency to strengthen cast iron, ferrite and pearlite, so it can increase the strength of cast iron. The tensile strength and bending strength of cast iron almost increase with the amount of copper in it, especially in low carbon cast iron.

- Q: What is the difference between forging parts and casting parts?

- Forging is in hot state through the metal hammer or press equipment produced by forging parts. A casting is a metal that is liquid and is poured into a cavity of a specified shape and cooled and solidified. It is the forging metal soft pinch molding, and casting the metal into thin cooling solidification.Forged parts are costly and have long production cycles.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- The performance is too extensive, I think the following several people all fall into the erroneous zone directly, the performance includes a series of aspects:Mechanical properties: tensile strength, yield strength, elongation and contraction ratio of section and impact toughness after etc.

- Q: What is the casting material?

- The casting material is usually made of gray cast iron, nodular cast iron and vermicular graphite cast iron

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine, according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

- Q: Heat treatment process and purpose of casting parts

- Methods: artificial aging or natural aging (also called normalization) treatment.Artificial aging: heating to 2-3 Baidu, it is best to apply mechanical vibration, and maintain a period of time.

- Q: What's the cause of the choking of the casting?,

- Causes of choking fire:1., casting material in the pouring of gas;

Send your message to us

Casted Ductile Iron Manhole Cover C250 for Mining with Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords