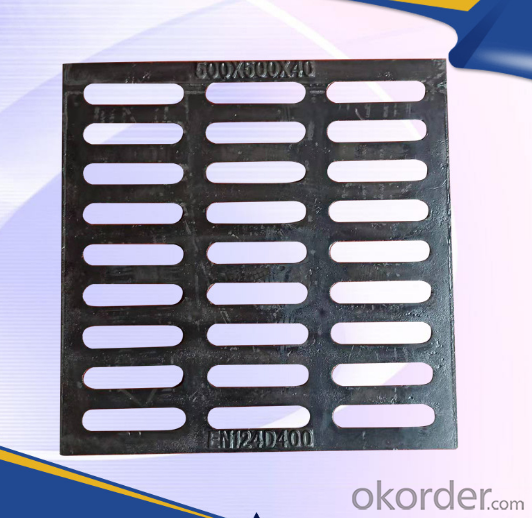

Casted Ductile Iron Manhole Covers C250 for Mining with Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| RGC-01L | C250 | 390*325 | 530*465 | 100 | 23 |

1.Standard:ISO9001,EN124

2.Applicable medium:gases,liquids,steam

3.Materail:ductile iron,Gray cast iron

Tested item standad

Anti-breaking strength (Mpa)>14

Impact toughness resistance (kg/cm2)>95

Tensile strength (Mpa)>10

Compressive strength (Mpa)>30

Modulus of elasticity(kg/cm2)>1.4*104

Cold-hot resistance measure<0.4

Water-absorption<1.0

Surface treatment

Black bitumen coated and hot gavanized

Smooth surface and anti-theft

Advantages

Good compressive, waterproof,anti-rust ,bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% or so lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Aluminum alloy die-casting parts or casting box and other parts of the threaded hole, in the case of processing conditions, it is best to use wire tapping or machine tool processing! Direct casting is not advocated.

- Q: What are the casting parts processing engineering?

- Among them, special casting has metal mould casting, pressure casting, low pressure casting, lost wax casting (also known as precision casting), shell casting, lost foam casting, centrifugal casting, continuous casting, V casting, and clay casting

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- Service performance: heat conductivity, friction reduction, shock absorption, heat resistance and corrosion resistanceTo compare these properties, it depends on the specific material, structure, and use of the parts. Otherwise, there is no comparisonS

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: What are the general technical requirements for casting parts?

- According to the national standard GB/T 9438, there are 8 aspects: 1. chemical composition; 2. delivery status; 3. mechanical properties; 4. dimensional tolerances; 5. weight tolerances; 6. appearance quality; 7. internal quality; 8. casting salvage.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- Processing stainless steel materials, you can use YG class tools, such as YG8, YG8N. The tool geometric parameters g0=15 degrees to 18 degrees, a0=6 degrees to 8 degrees, kr=75 degrees, ls=-5 degrees to -8 degrees; cutting amount is Vc=43 m/min, ap=0.3 to 0.5 mm, f=0.16mm/r.

- Q: How can the casting be free of trachoma?

- 2, pouring temperature should be enough, otherwise the sand can not float up;

Send your message to us

Casted Ductile Iron Manhole Covers C250 for Mining with Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords