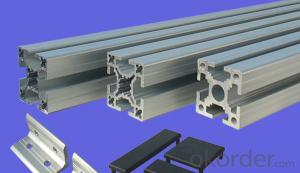

Cast Aluminum Handrail Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of rotomolding:

1) The cost of plastic rotational molding is low. For products in the same size, the cost of rotational mold is about 1/3 or 1/4 of that of blowing or injection mould.

2) Plastic rotational products have strong edge, from rotational molding the edge of the product can be more than 5mm, so the problem that the edges of hollow products are thin is completely solved.

3) In plastic rotational molding, variety of inserts can be placed.

4) The shape of rotational molding products can be very complex, and the thickness can be more than 5mm.

5) Rotational molding products can be produced fully closed.

6) Rotational molding products can be filled with foam material, to achieve thermal insulation.No need to adjust the mold, the thickness of rotational molding products can be adjusted.

7) No need to adjust the mold, the thickness of rotational molding products can be adjusted.

8) The products are hollow and seamless, but the thickness can be adjusted, so that the products are with high strength.

9) It’s available to deal with a variety of surface patterns and produce products in various colors. The treatment of anti-UV and anti-aging is possible; the simulation results of many kinds of stone and wood are also available. Our company has large imported CNC machine centers. With more than 20 years’ experiences of making aluminum rotational moulds, we can guarantee there is no needle porosity on the surface. We have been producing custom rotational products in various dimensions and shapes for domestic and foreign customers. We can produce molds according to customers’ drawing and design, making all kinds of rotational products for them.

- Q: What are the different bending options available for aluminum profiles?

- There are several bending options available for aluminum profiles, including cold bending, hot bending, and rotary draw bending. Cold bending is a common method that involves using a bending machine to gradually bend the aluminum profile without applying heat. Hot bending, on the other hand, requires heating the aluminum profile to a specific temperature before bending it. This method is usually used for thicker profiles or when tighter bending radii are required. Rotary draw bending is a precision bending technique that utilizes a mandrel and a rotating die to achieve accurate and consistent bends in aluminum profiles.

- Q: Can aluminum profiles be used for escalator steps?

- No, aluminum profiles are not typically used for escalator steps. Escalator steps are designed to bear significant weight and withstand constant foot traffic, making them subject to high levels of stress and wear. Therefore, escalator steps are usually made from durable materials such as steel or strong composite materials that can withstand heavy loads and provide long-lasting performance. While aluminum profiles may have various applications in architectural or industrial settings, they are not commonly used for escalator steps due to their comparatively lower strength and potential for deformation under heavy loads.

- Q: What's the price of aluminum alloy die castings and aluminum profiles?

- Aluminum alloy extrusion is a method of extruding cold drawn and extruded aluminum alloy through extrusion die. Aluminum alloy die casting is hot processing, melting aluminum alloy into the mold cooling molding, can be taken out from the mold, can be processed very complex products. What do you mean by "expensive"?

- Q: This question asks whether aluminum profiles can be joined using welding or bolting methods.

- <p>Yes, aluminum profiles can be both welded and bolted together. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity, but it is possible and results in a strong joint. Bolting is a common method for joining aluminum profiles, as it is quick, easy, and does not require melting the material. It is important to use appropriate hardware and techniques to ensure a secure and durable connection.</p>

- Q: 5002 and 6063 aluminum profiles difference

- 6063 is generally used in architectural profiles.The main alloy elements of 5002 aluminum alloy are magnesium and silicon, and form Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad action of iron.

- Q: What are the advantages of using aluminum profiles in the oil and gas industry?

- Using aluminum profiles in the oil and gas industry offers numerous benefits. First and foremost, aluminum profiles boast an exceptional strength-to-weight ratio. This means they provide excellent structural integrity while remaining lightweight, a crucial factor when transporting and installing equipment in different locations. Moreover, the lightweight nature of aluminum profiles reduces the strain on structures and equipment, resulting in energy savings and enhanced efficiency. Secondly, aluminum profiles exhibit remarkable resistance to corrosion. Given that the oil and gas industry often operates in harsh environments with exposure to saltwater, chemicals, and extreme temperatures, the natural oxide layer of aluminum acts as a protective barrier, ensuring durability and preventing corrosion. This corrosion resistance significantly reduces maintenance and replacement costs throughout the equipment's lifespan. Furthermore, aluminum profiles are non-magnetic, making them ideal for applications where magnetic interference is a concern. In the oil and gas industry, precision and accuracy are paramount, and the non-magnetic properties of aluminum profiles ensure that equipment operates without any electromagnetic interference, guaranteeing data accuracy and reliable performance. Additionally, aluminum profiles can be easily fabricated and customized to meet specific requirements. They can be extruded into various shapes, sizes, and configurations, providing endless design possibilities. This manufacturing flexibility makes aluminum profiles highly versatile, allowing them to be utilized in a wide range of applications within the oil and gas industry, such as pipe racks, platforms, support structures, and access systems. Lastly, aluminum is an environmentally friendly and sustainable material. It is 100% recyclable without losing its properties, making it an ideal choice for the oil and gas industry, which increasingly focuses on reducing its carbon footprint. The recyclability of aluminum also contributes to cost savings and resource conservation. In conclusion, the advantages of using aluminum profiles in the oil and gas industry encompass their high strength-to-weight ratio, corrosion resistance, non-magnetic properties, easy fabrication, and recyclability. These characteristics make aluminum profiles a dependable and cost-effective solution for various applications within this industry.

- Q: What unique considerations or criteria must be met when installing aluminum profiles in areas with heavy foot traffic?

- <p>When installing aluminum profiles in high-traffic areas, special requirements include selecting profiles with high load-bearing capacity, using durable materials resistant to wear and tear, and ensuring the profiles have slip-resistant surfaces. It's also crucial to consider the ease of maintenance and cleaning, as these areas will require more frequent upkeep. Additionally, profiles should be designed to withstand frequent contact and potential impacts, and they must comply with safety regulations to prevent accidents.</p>

- Q: What are the anti-static properties of aluminum profiles?

- The anti-static properties of aluminum profiles refer to their ability to prevent or dissipate static electricity buildup. Aluminum is a conductive material, allowing it to quickly discharge any static electricity that may accumulate on its surface. This property helps to prevent the buildup of electrostatic charges, which can be harmful to electronic components or cause problems in sensitive environments such as cleanrooms or manufacturing facilities.

- Q: Which is the highest price of aluminum profile 60616063?

- Generally speaking, 6061 of a little higher, but also depends on the quality, whether there is aging treatment, such as T6 status;6063, low silicon content, relatively soft, oxidation effect is better than 6061, suitable for appearance pieces, LED lamp holder, etc.; 6061, cutting performance is good, suitable for structural parts.

- Q: Can aluminum profiles be used for stage and truss structures?

- Yes, aluminum profiles can be used for stage and truss structures. Aluminum is a lightweight, durable, and versatile material that is commonly used in construction and engineering applications, including stage and truss structures. It offers excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication, making it an ideal choice for such purposes.

Send your message to us

Cast Aluminum Handrail Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords