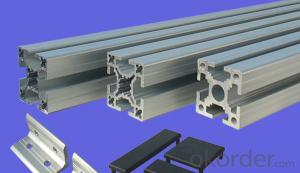

Cast Aluminum Handrail Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of rotomolding:

1) The cost of plastic rotational molding is low. For products in the same size, the cost of rotational mold is about 1/3 or 1/4 of that of blowing or injection mould.

2) Plastic rotational products have strong edge, from rotational molding the edge of the product can be more than 5mm, so the problem that the edges of hollow products are thin is completely solved.

3) In plastic rotational molding, variety of inserts can be placed.

4) The shape of rotational molding products can be very complex, and the thickness can be more than 5mm.

5) Rotational molding products can be produced fully closed.

6) Rotational molding products can be filled with foam material, to achieve thermal insulation.No need to adjust the mold, the thickness of rotational molding products can be adjusted.

7) No need to adjust the mold, the thickness of rotational molding products can be adjusted.

8) The products are hollow and seamless, but the thickness can be adjusted, so that the products are with high strength.

9) It’s available to deal with a variety of surface patterns and produce products in various colors. The treatment of anti-UV and anti-aging is possible; the simulation results of many kinds of stone and wood are also available. Our company has large imported CNC machine centers. With more than 20 years’ experiences of making aluminum rotational moulds, we can guarantee there is no needle porosity on the surface. We have been producing custom rotational products in various dimensions and shapes for domestic and foreign customers. We can produce molds according to customers’ drawing and design, making all kinds of rotational products for them.

- Q: What are the different surface protection options available for aluminum profiles?

- There are several surface protection options available for aluminum profiles, including anodizing, powder coating, painting, and laminate coating. Anodizing is a process that creates a durable and corrosion-resistant layer on the surface of the aluminum. Powder coating involves applying a dry powder to the surface, which is then heated to form a protective layer. Painting involves applying liquid paint to the surface, providing both protection and aesthetic appeal. Laminate coating involves applying a thin layer of protective material, such as plastic or wood, to the surface of the aluminum. Each option offers different benefits and is suitable for various applications.

- Q: What are the advantages of industrial aluminum profiles? What are the problems that should be paid attention to?

- Attention to the selection and application of aluminum profile:1. note the date of manufacture, specifications, technical conditions, enterprise name and production license number.2. products bright colors, good gloss, no defects.3. the product thickness is not less than 1.0mm.4. film thickness is not less than 10 m, coating thickness is not more than 40-120 m range.5. choose good corrosion resistant profiles.6., hard objects can not be used as cleaning tools.7. can be washed with water, washing soap and soap

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a specific project.

- <p>To calculate the amount of aluminum profiles needed for a project, first, determine the dimensions and design of the structure. Measure the length, width, and height of the required profiles. Consider the number of profiles needed for each section of the project. Multiply the length of each profile by the number of profiles required. Sum these totals for all sections to get the overall amount of aluminum needed. Factor in a margin for cutting and waste to ensure you have enough material. Consult with suppliers or use specialized software for more precise calculations, especially for complex projects.</p>

- Q: What are the different surface protection coatings for aluminum profiles?

- There are several different surface protection coatings available for aluminum profiles, each offering unique benefits and applications. Some common options include: 1. Anodizing: Anodizing is a widely used coating method that creates a protective layer on the surface of aluminum. It enhances the corrosion resistance, durability, and aesthetics of the profiles. Anodized coatings can be clear or colored, providing options for various design preferences. 2. Powder coating: Powder coating is a popular choice for aluminum profiles due to its durability and versatility. This coating method involves electrostatically applying dry powder to the surface, which is then cured under heat to form a protective layer. Powder coatings offer excellent resistance to UV rays, chemicals, and scratches, while also providing a wide range of color options. 3. Liquid paint coating: Liquid paint coatings are another option for protecting aluminum profiles. This method involves applying a liquid paint to the surface, which is then cured to form a protective film. Liquid paints offer flexibility in terms of color and finish, allowing for customization to meet specific design requirements. 4. E-coating: E-coating, also known as electrocoating or electrodeposition, is a method of applying a paint or coating to aluminum profiles using an electric current. This process creates a uniform and consistent coating, providing excellent corrosion resistance and durability. E-coatings are commonly used in automotive and industrial applications. 5. Ceramic coatings: Ceramic coatings are a newer option for protecting aluminum profiles. These coatings are composed of inorganic materials that provide exceptional hardness, heat resistance, and chemical resistance. Ceramic coatings can enhance the performance and lifespan of aluminum profiles in harsh environments, such as marine or aerospace applications. It is important to consider the specific requirements and intended use of the aluminum profiles when selecting a surface protection coating. Factors such as corrosion resistance, durability, aesthetics, and cost should be taken into account to determine the most suitable coating option.

- Q: What kind of self tapping screw can attack aluminum profile?

- General aluminum, iron, stainless steel can attack ah!

- Q: Can aluminum profiles be used for electrical cabinets?

- Indeed, electrical cabinets can employ aluminum profiles. Aluminum, a material that is both lightweight and sturdy, exhibits outstanding electrical resistance and thermal conductivity. Its durability and efficient heat dissipation make it a frequent choice for electrical cabinets. Aluminum profiles provide a robust structure for these cabinets, facilitating the effortless installation of wiring and electrical components. Moreover, aluminum profiles can be readily tailored and modified to meet precise design specifications, rendering them an optimal selection for electrical cabinets.

- Q: Are aluminum profiles suitable for medical equipment?

- Yes, aluminum profiles are suitable for medical equipment. Aluminum is lightweight, durable, and corrosion-resistant, making it an ideal material for constructing various medical devices and equipment. It also offers versatility in terms of design and can be easily customized to meet specific requirements. Additionally, aluminum profiles can be easily sterilized, making them suitable for use in medical settings where hygiene is crucial.

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Warehouse and storage systems can utilize aluminum profiles. These profiles possess qualities such as being lightweight, durable, and resistant to corrosion, which make them suitable for a variety of applications in warehouses and storage systems. They can be utilized for the construction of shelving units, racks, and partitions in order to optimize storage space and arrange inventory. Aluminum profiles are also highly versatile, allowing for easy customization and assembly to fulfill specific storage requirements. Furthermore, these profiles offer an exceptional strength-to-weight ratio, enabling them to support heavy loads without compromising the structural integrity. Overall, due to their durability, flexibility, and cost-effectiveness, aluminum profiles are widely preferred in warehouse and storage systems.

- Q: What are the electrical insulation properties of aluminum profiles?

- Aluminum profiles have relatively poor electrical insulation properties. Aluminum is a good conductor of electricity, meaning it allows the flow of electric current. However, aluminum profiles can be anodized or coated with insulating materials to enhance their electrical insulation properties.

- Q: Are aluminum profiles suitable for use in mining and construction equipment?

- Yes, aluminum profiles are suitable for use in mining and construction equipment. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for heavy-duty applications in these industries. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, enhancing their suitability for use in mining and construction equipment.

Send your message to us

Cast Aluminum Handrail Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords