Carrier Air Conditioner Aluminum Coil - PVDF Painted Aluminium Coil with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PVDF Painted Aluminium in Coil Form With Best Quality Description

PVDF Painted Aluminium in Coil Form With Best Quality is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of PVDF Painted Aluminium in Coil Form With Best Quality

PVDF Painted Aluminium in Coil Form With Best Quality | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

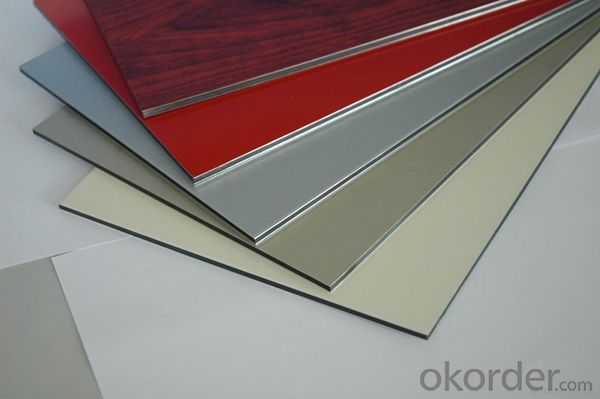

3. Application of PVDF Painted Aluminium in Coil Form With Best Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of PVDF Painted Aluminium in Coil Form With Best Quality

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of PVDF Painted Aluminium in Coil Form With Best Quality

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

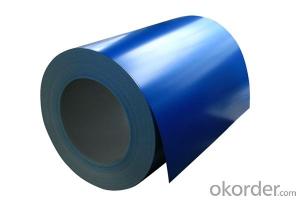

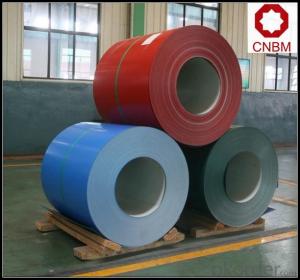

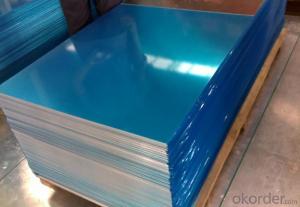

6. Image of PVDF Painted Aluminium in Coil Form With Best Quality

7. Package and shipping of PVDF Painted Aluminium in Coil Form With Best Quality

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in food processing applications?

- Food processing applications can utilize aluminum coils, as they offer a range of advantages. Aluminum is a widely used and highly adaptable material in the food industry due to its various benefits. Aluminum coils are lightweight, durable, and possess excellent thermal conductivity, which makes them suitable for applications requiring efficient and uniform heat transfer. When it comes to food processing, aluminum coils are commonly employed in equipment such as heat exchangers, evaporators, and refrigeration units. These coils help to cool, heat, or maintain the temperature of different food products during their processing, storage, or transportation. The exceptional thermal conductivity of aluminum ensures that heat is evenly dispersed, thereby aiding in the preservation of food quality and flavor. Furthermore, aluminum is a non-toxic and non-reactive metal, meaning it has no adverse effects on the taste or composition of the processed food. It is also naturally resistant to corrosion, ensuring that the coils do not contaminate the food and can be easily cleaned and maintained. In addition, aluminum is an environmentally friendly and recyclable material, aligning with the increasing demand for sustainable practices in the food industry. Its lightweight nature also contributes to energy efficiency and reduced transportation expenses. In conclusion, aluminum coils are a reliable, efficient, and safe choice for food processing applications. They meet the strict requirements of the industry while ensuring the quality and safety of the processed food.

- Q: What are the different tensile strengths of aluminum coils?

- The tensile strength of aluminum coils may differ based on the particular alloy and temper of the aluminum employed. Aluminum alloys, which are frequently used for coils, encompass 1100, 3003, 5052, and 6061. The tensile strength of these alloys can span from roughly 13,000 psi (90 MPa) for 1100 aluminum to approximately 45,000 psi (310 MPa) for 6061 aluminum. The temper of the aluminum also assumes a significant role in establishing its tensile strength. The prevailing temper for aluminum coils is H14, signifying that the material has undergone strain-hardening and partial annealing to attain a balance of strength and formability. Different tempers like H18, H24, and H32 can lead to higher tensile strengths, whereas softer tempers such as O (annealed) or H12 can result in lower tensile strengths. It is essential to acknowledge that these values are general ranges and may marginally deviate depending on the specific manufacturer and production process. Furthermore, factors like thickness, width, and surface treatment of the aluminum coils can also exert influence on their tensile strength. Consequently, it is advisable to refer to the manufacturer's specifications or conduct testing on the specific aluminum coil to accurately ascertain its tensile strength.

- Q: What are the different types of surface finishes for decorative purposes?

- There are several different types of surface finishes that are commonly used for decorative purposes. These finishes can enhance the appearance of a surface, adding texture, depth, and visual interest. Some of the most popular types of surface finishes for decorative purposes include: 1. Polished: Polished finishes are smooth and shiny, creating a reflective surface. This finish is achieved by polishing the surface using abrasive materials, resulting in a glossy appearance. 2. Matte: Matte finishes have a flat, non-reflective surface. They are achieved by using sandpaper or other materials to create a smooth but dull appearance. Matte finishes are often used to create a more subtle and understated aesthetic. 3. Brushed: Brushed finishes have a distinctive linear pattern that is created by brushing the surface with a wire brush or abrasive material. This finish is commonly used on metals, such as stainless steel, to create a textured and visually interesting look. 4. Textured: Textured finishes involve adding patterns or designs to the surface through various techniques. This can include embossing, engraving, or applying a textured coating. Textured finishes can add depth and dimension to a surface, creating a unique and visually appealing effect. 5. Antiqued: Antiqued finishes are designed to mimic the appearance of aged or weathered surfaces. This can be achieved through techniques such as distressing, staining, or adding a patina. Antiqued finishes are often used to create a vintage or rustic look. 6. Metallic: Metallic finishes use metallic pigments or coatings to create a shiny and reflective appearance. This finish can add a touch of elegance and sophistication to a surface, making it a popular choice for decorative purposes. 7. High gloss: High gloss finishes have an extremely smooth and reflective surface, creating a mirror-like effect. This finish is achieved by applying multiple layers of clear coat or lacquer and polishing the surface to a high shine. High gloss finishes are often used to create a modern and luxurious look. Overall, the choice of surface finish for decorative purposes depends on the desired aesthetic and the type of material being used. Each finish has its own unique qualities and can greatly enhance the overall visual appeal of a surface.

- Q: What is the role of aluminum coils in HVAC systems?

- The role of aluminum coils in HVAC systems is crucial for the efficient functioning of the system. Aluminum coils are an essential component of the air conditioning unit as they are responsible for transferring heat between the indoor and outdoor environments. When the air conditioning unit is in cooling mode, the aluminum coils act as evaporator coils. They help in absorbing heat from the indoor air, thus cooling it down. The warm air from the room passes over the cold aluminum coils, and the heat is transferred to the refrigerant flowing through the coils. This process cools the air and removes moisture, resulting in the desired cooling effect. In heating mode, the aluminum coils function as condenser coils. They receive the hot refrigerant from the compressor and transfer the heat to the surrounding air. This hot air is then distributed throughout the building, providing warmth during colder weather. Aluminum coils are preferred in HVAC systems due to their excellent heat transfer properties and resistance to corrosion. They are lightweight, durable, and have a high thermal conductivity, allowing for efficient heat exchange. Moreover, aluminum coils are more environmentally friendly compared to other materials like copper, as they are easier to recycle. Regular maintenance and cleaning of the aluminum coils are necessary to ensure optimal performance and prevent any airflow restrictions caused by dust, dirt, or debris buildup. Neglecting coil maintenance can lead to reduced cooling or heating capacity, decreased energy efficiency, and potential system breakdowns. Overall, aluminum coils play a vital role in HVAC systems by facilitating the heat transfer process, enabling efficient and effective temperature control in both cooling and heating modes, and contributing to the overall comfort and functionality of the system.

- Q: What types of aluminum coils are there that are designed for particular applications?

- <p>Yes, there are various types of aluminum coils designed for specific purposes. For instance, there are coils for construction, which are often used for roofing and siding. Coils for automotive applications are used in manufacturing car parts. Reflective coils are ideal for heat reflection in industries like food processing. Coils for electrical applications are used in transformers and wiring. Each type has specific properties like thickness, strength, and surface finish tailored to meet the requirements of their respective industries.</p>

- Q: What’s the difference between natural cooling and slice cooling?

- Cooling with furnace means after thermal insulation, stop heating furnace and make the parts in the furnace cool slowly to the room temperature with the furnace. Natural cooling is a kind of cooling method utilizing fluid circulation based on the fact that density varies with temperature to remove hea

- Q: Aluminium forms layer of aluminium oxide when exposed to air. This prevents further reaction.However, isn't aluminium oxide an amphoteric oxide that can react with both acids and alkalis?

- Aluminium forms layer of aluminium oxide when exposed to air. This prevents further reaction WITH AIR.

- Q: I heared the aluminum weakens or melts.

- Mercury readily combines with aluminium to form a mercury-aluminum amalgam when the two pure metals come into contact. However, when the amalgam is exposed to air, the aluminium oxidizes, leaving behind mercury. The oxide flakes away, exposing more mercury amalgam, which repeats the process. This process continues until the supply of amalgam is exhausted, and since it releases mercury, a small amount of mercury can “eat through” a large amount of aluminium over time, by progressively forming amalgam and relinquishing the aluminium as oxide. Aluminium in air is normally protected by a thin layer of its own oxide, which is not porous to mercury. Mercury coming into contact with this oxide does no harm. However, if any elemental aluminium is exposed (even by a recent scratch), the mercury may combine with it, starting the process described above, and potentially damaging a large part of the aluminium before it finally ends.

- Q: Can aluminum coils be used in signage applications?

- Yes, aluminum coils can be used in signage applications. Aluminum is a popular material for signage due to its durability, lightweight nature, and resistance to corrosion. It can be easily formed into various shapes and sizes, making it suitable for different types of signage, including billboards, nameplates, and outdoor signs. Additionally, aluminum can be painted or laminated to achieve different visual effects and enhance the overall appearance of the signage.

- Q: What are the different coil packaging options for aluminum coils?

- Customers have several choices when it comes to packaging aluminum coils. One option is the wooden crate, which provides excellent protection during transportation and storage. These crates are made of sturdy wood and are designed to securely hold the coils in place, preventing any damage. Metal bands or straps are often used to further secure the coils. Another popular choice is the steel cage, which is durable and offers exceptional protection. These cages are made of heavy-duty steel and can withstand the demands of transportation. Like wooden crates, steel cages are equipped with straps or bands to prevent movement and damage. Stretch wrap and shrink wrap are also used for packaging aluminum coils. Stretch wrap is a plastic film that tightly wraps around the coils, creating a protective layer. Shrink wrap, on the other hand, is a plastic film that is heated and shrinks tightly around the coils. Both options provide protection against dust, moisture, and other environmental factors. Some companies may choose customized packaging solutions, such as custom-made crates or containers, to meet their specific needs. These solutions can be tailored to accommodate the size, weight, and other unique requirements of the coils, ensuring maximum protection. Overall, customers can choose from wooden crates, steel cages, stretch wrap, shrink wrap, or customized packaging solutions for their aluminum coil packaging needs. Each option offers different levels of protection, allowing customers to choose what suits their requirements and budget.

Send your message to us

Carrier Air Conditioner Aluminum Coil - PVDF Painted Aluminium Coil with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords