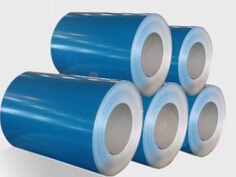

Capri Blue PPGI Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

PPGI Coil1.Common polyester paint

2.50-150g/m2 dipped layer

3.2 Coating 2 Baking process

4.Long life span

PPGI Coil

Brief Introduction

1. PPGI Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for PPGI Coil is HDG steel. The finish coats of PPGI Coils can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

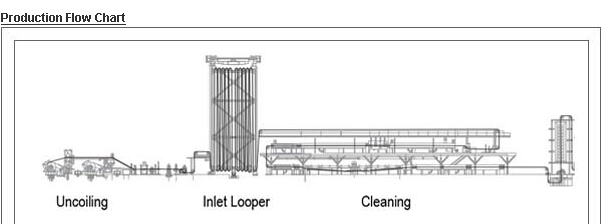

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the PPGI Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The PPGI Coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

- Q: What are the different types of steel beams used in building structures?

- There are several different types of steel beams commonly used in building structures, including I-beams, H-beams, W-beams, and C-beams. These beams vary in shape and size, with each type designed to provide specific load-bearing capabilities and structural support. I-beams, for example, have a distinctive I shape and are widely used for horizontal support in buildings. H-beams, on the other hand, have a wider flange and are commonly used in heavy-duty applications. W-beams are similar to I-beams but have a wider flange, providing increased support for larger loads. C-beams, also known as channel beams, have a C-shaped cross-section and are often used for various structural and framing purposes. Overall, the choice of steel beam type depends on the specific requirements and design specifications of the building structure.

- Q: What are the uses of steel wire mesh in agriculture?

- Steel wire mesh has several uses in agriculture. It is commonly used as fencing to protect crops and livestock from external threats such as animals or trespassers. Additionally, steel wire mesh is used as a trellis system for supporting climbing plants like tomatoes, beans, or grapes, ensuring their proper growth and maximizing yield. It can also be utilized as a protective covering for fruit trees or vegetable beds, preventing damage caused by birds or insects. Overall, steel wire mesh is a versatile tool that aids in securing and enhancing agricultural practices.

- Q: What are the different types of steel beams?

- There are several different types of steel beams, including I-beams, H-beams, W-beams, and channel beams. Each type of beam has its own specific shape and dimensions, making them suitable for different structural applications.

- Q: How are steel products used in the chemical industry?

- Steel products are widely used in the chemical industry for various applications such as storage tanks, pipelines, reactors, and other equipment. The durability and resistance of steel make it suitable for handling corrosive and high-pressure substances. Additionally, steel's high melting point allows it to withstand extreme temperatures in chemical processes. Overall, steel products play a critical role in ensuring the safe and efficient handling of chemicals in the industry.

- Q: What are the different types of steel chains and their applications?

- There are several types of steel chains, each designed for specific applications. Some common types include: 1. Grade 30 chains: These chains are general-purpose chains commonly used in applications such as towing, logging, and agriculture. 2. Grade 43 chains: Also known as high-test chains, they have a higher tensile strength and are ideal for heavy-duty applications like load securement and transportation. 3. Grade 70 chains: These chains are specifically designed for transportation and tie-down applications. They have a high strength-to-weight ratio, making them suitable for securing heavy cargo. 4. Grade 80 and Grade 100 chains: These chains are extremely strong and commonly used in lifting and rigging applications. They are capable of withstanding heavy loads and are often used in construction and industrial settings. 5. Stainless steel chains: These chains are corrosion-resistant and ideal for applications where exposure to moisture or chemicals is a concern. They are commonly used in marine environments, food processing, and medical equipment. Each type of steel chain has its own unique properties and applications, so it is essential to choose the appropriate chain based on the specific demands of the task at hand.

- Q: How are steel products used in the construction of religious buildings and places of worship?

- Steel products are commonly used in the construction of religious buildings and places of worship due to their strength, durability, and versatility. Steel beams and columns provide structural support, ensuring the stability of the building. Steel roofing and cladding offer protection against the elements, while steel doors and windows enhance security. Additionally, steel is often used for decorative purposes, such as ornamental gates or intricate railings, adding to the aesthetic appeal of religious structures. Overall, steel products play a crucial role in creating safe, long-lasting, and visually appealing religious buildings and places of worship.

- Q: What are the different types of steel products used in the manufacturing of medical equipment?

- There are several types of steel products used in the manufacturing of medical equipment, including stainless steel, carbon steel, and alloy steel. Stainless steel is commonly used due to its corrosion resistance and ability to withstand sterilization processes. Carbon steel is often used for structural components, while alloy steel is utilized for its strength and durability in specialized applications.

- Q: What are the advantages of using structural steel in construction?

- There are several advantages of using structural steel in construction. Firstly, structural steel is known for its strength and durability, making it a reliable choice for constructing buildings that need to withstand heavy loads and severe weather conditions. Additionally, steel is a versatile material that can be easily manipulated and shaped into various forms, allowing for creative and innovative architectural designs. Moreover, steel is highly cost-effective as it is readily available and can be fabricated off-site, reducing construction time and labor costs. Lastly, structural steel is also sustainable as it can be recycled, reducing environmental impact and promoting a circular economy. Overall, the advantages of using structural steel in construction include its strength, versatility, cost-effectiveness, and sustainability.

- Q: How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities. They provide structural support and durability, ensuring the safety and integrity of the buildings. Steel beams, columns, and frames are commonly used to create large open spaces, allowing for flexible layouts and accommodating various equipment and machinery. Additionally, steel is resistant to fire, corrosion, and pests, making it an ideal choice for laboratories where hazardous materials and sensitive experiments are conducted. Overall, steel products are essential components in creating efficient, functional, and secure research facilities.

- Q: How does steel tube bending work?

- Steel tube bending works by applying force to a straight steel tube to deform it into a desired curved shape. This force is typically exerted through a combination of heat and mechanical pressure, which softens the steel and allows it to be bent without breaking. Different methods, such as mandrel bending or induction bending, are used depending on the size and thickness of the tube.

Send your message to us

Capri Blue PPGI Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords