Butterfly Valve OEM Flange Connection 1 Inch Double Flange

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Butterfly Valve

(1) 90° movement for full open/close position.

(2) Excellent control characteristics.Tight shut-off even after innumerable operations.

(3) Installation cost considerably reduced because of very low weight and compact design.

(4) Longer life and reliable service with minimum component wear.

(5) Renewable seats. No supplementary gasket required with the adjacent pipework.

(6) Body & Stem totally protected from service fluid.

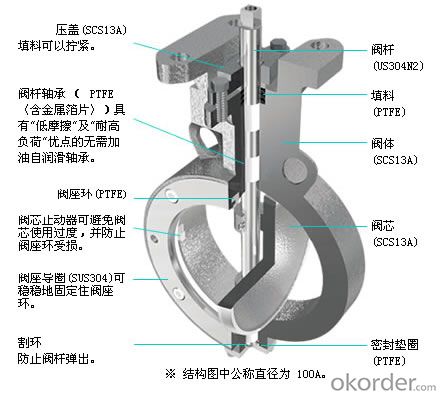

3. Butterfly Valve Images:

4.Butterfly Valve Specification:

BODY | DISC | STEM | SEAT | BUSHING | |

MATERIAL | WORKING PRESSURE | ||||

CAST IRON | DUCTILE IRON WITH NICKEL PLATED | CARBON STEEL | NR | -20-+85 | LUBRIZED BRONZE |

DUCTILE IRON | ALUMINUM BRONZE | STAINLESS | HYPALON | -18-+135 INSTANTANEOUS -18-+149 | PTFE |

ALUMINUM | STAINLESS STEEL | EPDM | -45-+135 INSTANTANEOUS -50-+150 | ||

CARBON STEEL | CARBON | NEOPRENE | -7-+193 INSTANTANEOUS -7-+107 | ||

STAINLESS STEEL | NBR | -12-+82 INSTANTANEOUS -12-+93 | |||

WEAR-RESISTANT RUBBER | -10-+50 | ||||

VITON | -23-+150 | ||||

HEAT-RESISTANT RUBBER | -20-+150 | ||||

PTFE | +10-+150 | ||||

5.FAQ

1. What is manual wafer butterfly valve?

Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What's the difference between a clip on handle butterfly valve and a turbo butterfly valve? Where are they used?

- 1, the drive mode is different (handle or turbine), mainly based on the size of the valve and the opening and closing torque to decide.2. The butterfly plate of the worm valve is installed in the direction of the diameter of the pipe. In the butterfly valve body cylindrical channel, the disc shaped butterfly plate revolves around the axis, the rotation angle is 0 degrees ~90 degrees between, when rotates to 90 degrees, the valve opens the card completely.3, clip type butterfly valve is to use double headed bolts to connect the valve between the two pipe flanges, flange butterfly valve is a valve with a flange, bolt with the valve flange at both ends connected to the pipe flange.

- Q: Butterfly valve model D344H and D343 difference

- In fact, almost all refers to the sealed variable eccentric butterfly valve.1, D344H-10C DN4002, D343H-10C DN400Let's talk about the similarities between the 2 Butterfly models: D stands for butterfly valves, 3 represents turbine drivers, and the middle 4 represents flanged connections,10 represents the pressure of 10 kg, C represents the butterfly valve, the material is cast steel, and DN400 stands for the caliber of the valve;To say that where there are differences between the 2 models, there is a place where there are differences, second means 4 of the first models is the new type sealing valve structure is variable eccentric, second of the second models of the 3 represents the structure of the valve is three eccentric, and three eccentric seal variable eccentric type is in fact a meaning.Sealed three eccentric butterfly valve, sealed variable eccentric butterfly valve, corresponding to the central butterfly valve and sealed single eccentric butterfly valve.

- Q: Import electric butterfly valve which brand is more reliable?

- Recommend Sichuan Ding Heng petroleum machinery company sales agent SPM butterfly valve and FMC butterfly valve, we are partners for many years, have been working together are very happy.

- Q: How warm is the PTFE butterfly valve?

- Ordinary PTFE clip butterfly valve normal temperature tolerance of about 120 degrees, instantly to about 150 degrees

- Q: What's the difference between cut-off valve, gate valve and butterfly valve? What's the difference in the working principle?

- Stop valve, leak small, gate valve, leak big, butterfly valve switch fast

- Q: How to use the fire butterfly valve properly?

- Clamp and groove type and signal butterfly valve, the first two have what requirements of installation, the operating handle can rotate to open and close the valve installation, signal wiring, mouth down, to prevent water and caused a short circuit three line grounding and alarm line for leakage protection and monitoring of the valve open or closed, general are in line with the alarm valve or flow indicator matched with water, indicating the spacing of not less than 300mm, no other special requirements

- Q: Who can give me a download UG butterfly valve, needle valve, diaphragm valve standard model address, Japanese standard, American Standard.

- Support many 3D CAD format, such as the commonly used UG, Pro/E, SolidWorks......As for the butterfly you said, don't post the link up, the standard JIS, American Standard ANSI, German standard DIN are.You use Baidu Search "LinkAble PARTcommunity", after the open registration, CAD format, such as UG, ASAHI and then to find the manufacturer home page, which is the valve, you said the Japanese standard, German standard, American Standard valve basically all.

- Q: How can the flange butterfly valve be installed on the pipe?

- Direction.Butterfly valve in theory can be installed in any direction, it is recommended that the horizontal installation of the valve shaft installation, so that both ends of the bearings will not be at the bottom (below), so as to avoid sediment in the media into the bearing.Inlet pipe configuration.There are water inlet side valve elbow, tee pipe fluid caused by bending and uneven distribution of the inflow valve, the drift will occur in the pipe, so it must be generated by the uniform drift disposed on both sides of the disc, so as to avoid uneven force on both sides of the disc, and may produce additional torque.

- Q: Butterfly valve in the use of the difference? Caliber?

- According to the function and use of the valve and butterfly valve, gate valve, small flow resistance, good sealing performance, the valve plate and the flow direction of the medium is the vertical angle, if the valve is not in place in the valve plate switch, wash medium on the valve plate of the valve plate is easy to fibrillation, according to valve seal damage.Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.

- Q: I HAVE A 2003 FORD EXPEDTION THAT IS IDLE ROUGH,AND WILL EVENTUALLY STALL. TODAY I FOLLOWED THE PCV VALVE HOSE TO THE BACK OF THE THROTTLE BODY AND NOTICED THERE IS A BIG HOLE ON THE ELBOW OF THE HOSE. HOW CAN I CHANGE IT? CAN I JUST FORCE THE HOSE OUT AND SIMPLY PUT A NEW ONE? BEEN HAVING THIS ROUGH IDLE /STALL PROBLEM FOR A WHILE I CLEANED IAC VALVE, THROTTLE BODY CHANGED THE AIR FILTER AND ALSO CLEANED THE MASS AIR FLOW SENSOR, I HAVE A P0171 system to lean(bank 1) code

- So, the rubber elbow hose has a hole in it. Your best bet is to get the replacement from the Ford dealer. Yes, you can buy just the elbow part from the parts counter at the dealer. If they start acting all dumb (and won't help you or sell you the part) then, go to a different dealer for the part. Another thing you could try is a used one from the junk yard BUT, it's been my experience that the rubber gets too hard and the PCV valve needs a lot of encouragement to be removed. Sometimes you'll damage the used elbow by trying to get it off of the engine or removing the old PCV valve to put in your replacement valve. That's why I recommend getting a new one straight from the source. They are pretty simple to change with ordinary hand tools and some mechanical know-how. You just pull the elbow off of the port that it's attached to on the engine. The valve will probably have a steel clip that goes around the hose at one end of the valve inside of the hose. You simply squeeze the clip with a pair of pliers and tug at the valve until it comes out of the elbow.

Send your message to us

Butterfly Valve OEM Flange Connection 1 Inch Double Flange

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords