Butterfly Valve Isolating or Regulating Flow U Type FF RF Pisition-Off 360 ISO 5211

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Butterfly Valves

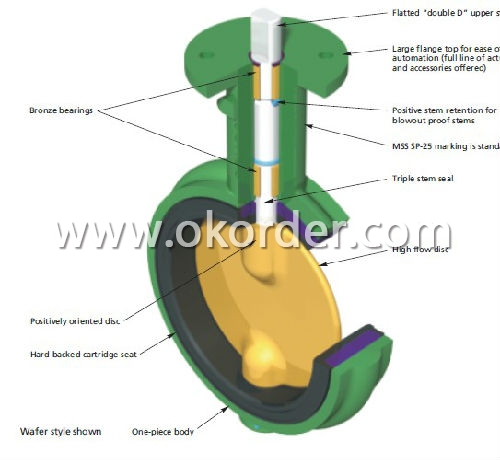

Concentric Butterfly Valve has a resilient rubber seat with a metal disc.

This type of butterfly valves can be used for isolating or regulating flow.

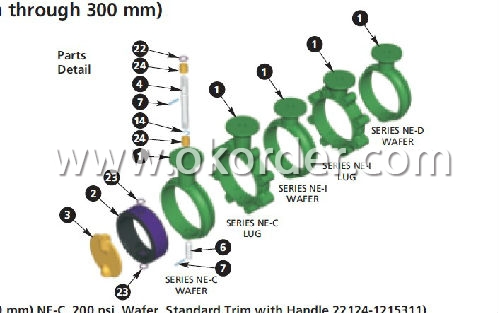

Wafer, Lug or U type flanged body style fit between FF or RF flanges

PTFE bushing ensure the maximum shaft support and centralized alignment

360°polished disc assures positiveon-off

Hard-Backed Cartridge seat or Edge-Boot seat

The pin,spline or square connection are all available

Universal ISO 5211 mounting pad

Technical Data of Butterfly Valves

| Size | DN40-DN1200 |

| General Design | ISO 5752/BS 5155/API 609 |

| Mounting Pad | ISO 5211 |

| Face to Face | API 609/EN 558-1 20 series etc. |

| Flange Drilling | DIN 2501 PN10/16 |

| Inspection and Test | API 598 |

﹡For all available general design, face to face standard and flange drilling,please kindly contact CNBM directly.

Materials of Parts

| Parts | Description | MaterialMaterial |

| 1 | Body | Cast Iron/Ductile Iron/WCB |

| 2 | Bushing | PTFE/Bronze |

| 3 | O-ring | EPDM/NBR |

| 4 | Shaft | Stainless Steel |

| 5 | Disc | Stainless Steel/Al-Bronze/Ductile Iron |

| 6 | Seat | EPDM/NBR/VITON/PTFE |

| 7 | Pin | Stainless Steel |

﹡For other material request,please kindly contact CNBM directly.

- Q: What does "D341X-16Q" mean?What do D341-16Q letters and numbers mean for butterfly valves?

- D - valve type code: Butterfly valve;3 - valve drive mode code: worm gear;4 - valve connection form code: flange;1 - valve structure type code: vertical plate type;X - seat sealing surface or lining material code: rubber;16 - nominal pressure value: PN1.6MPa;Q - body material code: QT400 - 15.

- Q: Butterfly valve common faults and treatment methods?

- Three, summary:Only familiar with every detail of circulating water pump outlet valve and butterfly valve equipment, timely and thorough maintenance and strict debugging, to ensure the safety and reliability of equipment operation, to ensure the healthy and orderly operation of equipment.

- Q: How big is the butterfly valve with a diameter of 80?

- With the 80 caliber butterfly valve.Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid.

- Q: What do D71, D371 and D341 represent in butterfly valves?

- D71 is a handle to clip butterfly valveD371 is a turbine to clip butterfly valveD341 is a manually operated double flanged butterfly valve

- Q: What is the medium flow rate when the centerline butterfly valve is fully open?

- The pressure test of the central butterfly valve is carried out at each station.Basis:1) GB/T12238-2008 flange and clamp connection elastic seal butterfly valveRules: butterfly valve must be carried out by factory inspection and testing, inspection qualified before leaving the factory.2) CJ/T 261-2007, butterfly valves for water supply and drainageRules: each product shall be inspected by factory and quality inspection department.

- Q: I went online to check where was the pcv valve for a 2001 ford focus, but I didn't find it. Does anyone have a picture? Thanks

- Its on the front of a line that looks like a big black t and it is very hard to notice.

- Q: What are the major disadvantages of butterfly valves?

- Shortcoming:A. operating torque is large, such as larger diameter or high pressure, it needs to be equipped with larger actuators;B. leakage is large, ordinary type is 2%C;C. as the adjustment of some butterfly valve, its rotation angle is limited to 60. Adjustable range is small.

- Q: Butterfly valve is generally used in what position?

- Butterfly valve used in furnace, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, environmental protection, chemical smelting and power building water supply and drainage engineering system in conveying a variety of corrosive and non corrosive media pipeline, used to adjust and cut off the media flow. It can also be used for switch control of low pressure pipeline medium.

- Q: What type of butterfly valves do you have in DN125?

- The butterfly type according to the usage, and there are many kinds of driving modes, different means, generally expressed as follows: Butterfly symbol: D; 1, drive mode: 0: 1: electromagnetic solenoid valve; hydraulic; electro hydraulic; 2: 3: 4: worm gear; spur gear 5: bevel gear;; pneumatic; 6: 7: 8: gas - Hydraulic; hydraulic; 9: Electric; handle, handwheel: no code. Connection: 2, valve is generally only two, 4: 7: flange type; clamp; 3, butterfly valve structure code: divided into sealed and non sealed type two; seal type: 0: 1: single eccentric; vertical center; 2: 3: three double eccentricity; eccentricity; 4: linkage; sealing type: 5: 6: single eccentric; vertical center; 7: 8: three double eccentricity; eccentricity; linkage mechanism: 9. 4, the sealing material: This lot, watch some kinds of H:Cr13 stainless steel; lining; J: S: X: plastic; rubber; for example: D971X: refers to the electric clamp center vertical plate rubber sealing butterfly valve.

- Q: Which is better, the round two lobe butterfly valve?

- The company has advanced sheet metal CNC processing line, strong technical force and strong production capacity. At present, the main products are: air outlet, air valve, muffler, fire damper, static pressure box, wind box, etc.. Especially round type double butterfly butterfly valve has obvious advantages.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;North America;Asia;Africa |

| Company Certifications | ISO9001:2008 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 20-50 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 8,350 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Butterfly Valve Isolating or Regulating Flow U Type FF RF Pisition-Off 360 ISO 5211

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords