BS4449 B460B Steel Rebar/Deformed bar Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

Square,U Channel,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

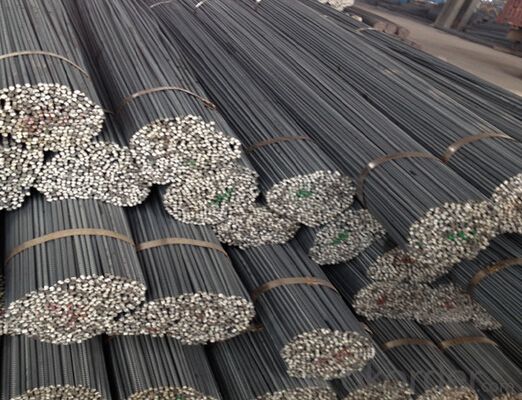

BS4449 B460B Steel Rebar/Deformed bar Made in China

Details of the BS4449 B460B Steel Rebar/Deformed bar Made in China

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the BS4449 B460B Steel Rebar/Deformed bar Made in China

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the BS4449 B460B Steel Rebar/Deformed bar Made in China

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: How are steel rebars protected against lightning strikes?

- Steel rebars are protected against lightning strikes through a process known as "bonding." During the construction of a structure, steel rebars are connected to a lightning protection system to redirect the electrical energy from a lightning strike safely into the ground. This system typically consists of lightning rods or air terminals installed at the highest points of the structure, which attract the lightning strike. The rebars are then interconnected with conductor cables, creating a network that ensures the lightning current is effectively grounded. The conductor cables are attached to the lightning rods and extend down the structure, connecting with the rebars at various points. By bonding the rebars with the lightning protection system, the electrical charge from a lightning strike is efficiently conducted away from the structure and harmlessly discharged into the ground. Furthermore, additional measures such as surge protection devices are often installed to further protect the rebars and the overall structure from potential damage caused by voltage surges resulting from lightning strikes. These surge protection devices help to minimize the risk of electrical surges that could potentially compromise the integrity of the rebars. In summary, steel rebars are protected against lightning strikes by being properly bonded to a lightning protection system. This ensures that the electrical energy from a lightning strike is safely directed away from the structure and grounded, reducing the risk of damage to the rebars and the overall structural integrity.

- Q: Can steel rebars be used in the construction of hospitals and healthcare facilities?

- Yes, steel rebars can be used in the construction of hospitals and healthcare facilities. Steel rebars provide structural integrity and strength to the buildings, ensuring their safety and durability. Additionally, steel rebars are resistant to fire, moisture, and corrosion, making them suitable for healthcare facilities that require high standards of cleanliness and hygiene.

- Q: What are the guidelines for storing steel rebars on a construction site?

- The guidelines for storing steel rebars on a construction site typically include keeping them off the ground to prevent rust and corrosion, stacking them neatly and securely to avoid accidents, and protecting them from exposure to moisture and other harmful elements. It is also important to separate different sizes and types of rebars to ensure easy identification and accessibility when needed.

- Q: What are the standards and specifications for steel rebars?

- The standards and specifications for steel rebars vary depending on the country and industry. However, some common standards followed globally include ASTM A615/A615M, ASTM A706/A706M, BS 4449:2005, and EN 10080. These standards define the requirements for the chemical composition, mechanical properties, dimensions, and tolerances of steel rebars used in construction and infrastructure projects. Additionally, specific projects or organizations may have their own additional specifications to ensure the quality and performance of the rebars.

- Q: How do steel rebars affect the overall sustainability of a construction project?

- The overall sustainability of a construction project can be significantly influenced by steel rebars. To begin with, steel rebars are commonly employed to reinforce concrete structures, thereby enhancing their strength and durability. This leads to an increase in the longevity of the building, consequently minimizing the necessity for frequent repairs or replacements. As a result, the consumption of materials and energy required for maintenance over the long term is reduced. Additionally, the utilization of steel rebars contributes to the structural integrity of a construction project, enabling the design of lighter and more efficient structures. This, in turn, leads to a reduction in material usage and lower energy consumption during the construction process. Moreover, the use of steel rebars often allows for the construction of slimmer and more aesthetically pleasing structures, which can positively impact the project's environmental footprint. Moreover, steel rebars are recyclable, further enhancing the sustainability of a construction project. At the end of a building's life cycle, it is easy to recover and reuse steel rebars, thereby reducing the demand for new steel production. This not only conserves natural resources but also significantly reduces greenhouse gas emissions associated with the steel manufacturing process. Furthermore, steel rebars can contribute to the overall sustainability of a construction project by improving the building's resilience to natural disasters such as earthquakes or hurricanes. By providing additional strength and flexibility to the structure, steel rebars can help minimize damage and potentially save lives. In conclusion, the usage of steel rebars positively affects the overall sustainability of a construction project by enhancing the structural integrity and durability of buildings, reducing material and energy consumption, promoting recycling and reuse, and improving resilience to natural disasters. Their utilization is a vital component in the creation of more sustainable and environmentally friendly construction practices.

- Q: Can steel rebars be used in high-security facility construction?

- Yes, steel rebars can be used in high-security facility construction. Steel rebars are strong and durable, making them a suitable choice for reinforcing concrete structures. In high-security facilities, such as prisons or government buildings, it is crucial to ensure the construction materials provide maximum strength and resistance against potential threats. Steel rebars offer excellent tensile strength, which helps reinforce concrete and enhance the overall structural integrity of the building. Additionally, steel rebars can be customized to meet the specific security requirements of the facility, such as using thicker rebars or increasing their spacing for added reinforcement. Therefore, steel rebars are commonly used in high-security facility construction to provide a robust and secure infrastructure.

- Q: Are steel rebars suitable for use in foundation structures?

- Yes, steel rebars are suitable for use in foundation structures. They provide strength and reinforcement to concrete, enhancing its load-bearing capacity and durability. Steel rebars are commonly used in foundation construction due to their high tensile strength and ability to withstand heavy loads and stress.

- Q: How are steel rebars protected against corrosion in aggressive environments?

- Various methods are utilized to protect steel rebars from corrosion in aggressive environments. One commonly employed approach involves the application of protective coatings. These coatings are administered to the surface of the rebars, establishing a barrier between the steel and the corrosive elements present in the surroundings. Examples of protective coatings comprise epoxy, zinc, and polyethylene coatings. Furthermore, cathodic protection is another means of safeguarding steel rebars. This technique involves linking the rebar to a sacrificial anode, often composed of a more reactive metal like zinc or magnesium. By doing so, the anode corrodes instead of the rebar, effectively sacrificing itself to shield the steel against corrosion. Additionally, corrosion inhibitors can be utilized to protect steel rebars. These inhibitors can be incorporated into the concrete mixture or directly applied to the rebars. Their function is to diminish the corrosive potential of the environment or form a protective film on the surface of the rebar, curtailing corrosion. Moreover, proper design and construction practices can play a pivotal role in preserving the integrity of steel rebars against corrosion. Sufficient concrete cover can aid in establishing a physical barrier between the rebar and the aggressive environment, thereby minimizing the steel's exposure to corrosive elements. Additionally, effective drainage systems and the use of non-corrosive aggregates contribute to the reduction of rebars' exposure to moisture and other corrosive substances. In summary, a combination of protective coatings, cathodic protection, corrosion inhibitors, and appropriate design and construction practices are employed to guarantee the protection of steel rebars in aggressive environments. These measures effectively prolong the lifespan of structures and uphold their structural integrity.

- Q: What are the different types of steel rebars available in the market?

- There are several types of steel rebars available in the market, including conventional carbon steel rebars, epoxy-coated rebars, galvanized rebars, stainless steel rebars, and high-strength rebars. Each type has specific properties and advantages depending on the intended application.

- Q: Can steel rebars be cut on-site during construction?

- Yes, steel rebars can be cut on-site during construction. Steel rebars are commonly used in reinforced concrete structures to provide strength and stability. During construction, it may be necessary to cut the rebars to specific lengths or shapes to fit the design requirements. This can be done using various tools such as rebar cutters, angle grinders, or oxy-fuel cutting torches. However, it is important to follow proper safety procedures and use appropriate protective gear when cutting rebars on-site to prevent any accidents or injuries.

Send your message to us

BS4449 B460B Steel Rebar/Deformed bar Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords