G460B deformed steel bar deformed steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering G460B deformed steel bar deformed steel bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

G460B deformed steel bar deformed steel bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's deformed steel bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of HRB400 Deformed Steel Bar:

Standard | GB | HRB400 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | Hebei, China mainland | ||

Advantages | exact size, regular package, chemical and mechanical properties are stable. | ||

Type | Hot rolled deformed steel bar | ||

Brand name | DRAGON | ||

Chemical Composition: (Please kindly find our chemistry of our material based on HRB500 as below for your information)

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

8 | 50.27 | 0.395 | 4.74 |

10 | 78.54 | 0.617 | 7.404 |

12 | 113.1 | 0.888 | 10.656 |

14 | 153.9 | 1.21 | 14.52 |

16 | 201.1 | 1.58 | 18.96 |

18 | 254.5 | 2.00 | 24 |

20 | 314.2 | 2.47 | 29.64 |

22 | 380.1 | 2.98 | 35.76 |

25 | 490.9 | 3.85 | 46.2 |

28 | 615.8 | 4.83 | 57.96 |

32 | 804.2 | 6.31 | 75.72 |

36 | 1018 | 7.99 | 98.88 |

40 | 1257 | 9.87 | 118.44 |

50 | 1964 | 15.42 | 185.04 |

Usage and Applications of HRB400 Deformed Steel Bar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of HRB400 Deformed Steel Bar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

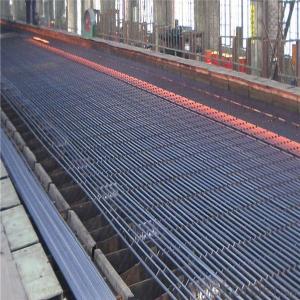

Deformed Steel Bar in container

Deformed Steel Bar in factory

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel rebars be used in thin concrete elements?

- Yes, steel rebars can be used in thin concrete elements. Rebars provide tensile strength to concrete, preventing cracks and enhancing its structural integrity. However, it is important to ensure proper spacing and cover requirements to avoid corrosion and maintain durability.

- Q: What are the considerations for using epoxy-coated steel rebars?

- When it comes to epoxy-coated steel rebars, there are several important factors that need to be taken into account. These factors include corrosion resistance, durability, cost-effectiveness, and construction requirements. One of the main factors to consider is the corrosion resistance provided by epoxy-coated steel rebars. The epoxy coating acts as a protective barrier against moisture, chemicals, and other corrosive elements commonly found in concrete structures. This coating significantly reduces the risk of corrosion, thereby increasing the lifespan of the rebar and the overall durability of the reinforced concrete. Durability is another crucial consideration. Epoxy-coated steel rebars are specifically designed to withstand harsh environmental conditions, including exposure to chloride ions that are known to accelerate corrosion in traditional black steel rebars. This enhanced durability ensures the structural integrity of the building over a longer period, reducing the need for expensive repairs or replacements. Cost-effectiveness is also an important factor to think about. Although epoxy-coated steel rebars may have a higher initial cost compared to black steel rebars, their long-term cost-effectiveness is evident. The reduced risk of corrosion and subsequent maintenance or repair expenses can result in significant savings over the lifespan of a structure. Additionally, the extended lifespan of the rebar can contribute to lower life-cycle costs. Construction requirements must also be considered when using epoxy-coated steel rebars. The application of the epoxy coating requires careful handling and storage to prevent damage or contamination. Special precautions must be taken during transportation, storage, and installation to maintain the integrity of the coating. Contractors must also undergo training and possess experience in working with epoxy-coated steel rebars to ensure proper installation and adherence to industry standards. In conclusion, the considerations for using epoxy-coated steel rebars encompass corrosion resistance, durability, cost-effectiveness, and specific construction requirements. Despite the higher initial cost and the need for additional care during handling and installation, the long-term benefits of increased corrosion resistance and durability make them a favorable choice for reinforced concrete structures.

- Q: How do steel rebars affect the overall vibration resistance of a structure?

- Steel rebars can significantly enhance the overall vibration resistance of a structure. By providing additional strength and stiffness, rebars increase the structural integrity and help to distribute and dissipate vibrational energy. This reinforcement effectively reduces the magnitude of vibrations and minimizes the risk of structural damage or failure during dynamic events, such as earthquakes or high winds.

- Q: How do steel rebars affect the durability of concrete structures?

- Steel rebars greatly enhance the durability of concrete structures. By reinforcing the concrete, rebars improve its tensile strength, preventing cracking and enhancing its ability to withstand external forces and loads. This reinforcement also helps to increase the overall lifespan of the structure, making it more resistant to corrosion, fatigue, and other forms of degradation.

- Q: What are the different types of steel coatings used on rebars?

- There are several types of steel coatings commonly used on rebars, including epoxy, galvanized, and stainless steel.

- Q: How is steel rebar made?

- Steel rebar, short for reinforcing bar, is made through a process known as steel reinforcement fabrication. The first step in making steel rebar is to melt down raw materials such as iron ore, coal, and limestone in a blast furnace. This process, known as smelting, produces molten iron. Next, the molten iron is refined and purified in a basic oxygen furnace, where impurities such as carbon, sulfur, and phosphorous are removed. This refining process ensures that the resulting steel has the desired strength and properties. After refining, the steel is then cast into billets, which are long, solid bars. These billets are then heated and rolled into thin, elongated strands known as rebars. The rolling process involves passing the billets through a series of rollers that gradually shape and elongate the steel. Once the rebars are formed, they are cooled and cut into desired lengths. These lengths can vary depending on the intended use of the rebar, such as reinforcing concrete in buildings, bridges, or other structures. To further enhance the strength and durability of the rebar, it can undergo a process called quenching and tempering. This involves heating the rebar to a high temperature and then rapidly cooling it, followed by reheating and slow cooling. This process helps to improve the rebar's mechanical properties, making it more resistant to wear, corrosion, and other external forces. Finally, the rebar goes through a surface treatment process, such as hot-dip galvanizing or epoxy coating, to protect it from rust and corrosion. This coating ensures that the rebar maintains its structural integrity and longevity when used in various construction applications. Overall, the production of steel rebar involves a series of steps including smelting, refining, casting, rolling, cutting, heat treatment, and surface coating. These processes ensure that the final product meets the necessary strength and durability requirements for reinforcing concrete structures.

- Q: How do steel rebars affect the constructability of complex architectural designs?

- Steel rebars play a crucial role in the constructability of complex architectural designs. These reinforced bars provide structural integrity and strength to concrete elements, making it possible to create intricate and innovative designs. Firstly, steel rebars allow architects to design structures with larger spans and heights, as they provide the necessary load-bearing capacity. This is particularly important in complex designs that involve cantilevers, soaring roofs, or suspended floors, as the rebars distribute the loads evenly and prevent structural failure. Moreover, steel rebars enhance the constructability of complex architectural designs by enabling the creation of slender and lightweight structures. Since rebars are strong and durable, they can be used to reinforce thin concrete elements, reducing the overall weight of the structure. This not only enhances the aesthetic appeal of the design but also minimizes the amount of material required, resulting in cost savings during construction. In addition, steel rebars offer flexibility during the construction process. They can be easily bent and shaped to match the intricate geometries and curves of complex architectural designs. This allows architects to realize their creative vision by incorporating unique and eye-catching elements into the structure. Furthermore, steel rebars contribute to the durability and longevity of complex architectural designs. By reinforcing the concrete, they increase its resistance to cracking, bending, and corrosion. This is especially important in areas prone to seismic activity or harsh weather conditions. The use of rebars ensures that the structure can withstand these challenges and remain intact over time. Overall, steel rebars significantly impact the constructability of complex architectural designs. Their strength, versatility, and ability to reinforce concrete elements make it possible to create innovative structures that are both visually appealing and structurally sound. Without the support of steel rebars, the construction of such complex designs would be much more challenging, if not impossible.

- Q: What are the different methods for reinforcing concrete with steel rebars?

- Some of the different methods for reinforcing concrete with steel rebars include placing the rebars in a grid pattern throughout the concrete structure, using stirrups or ties to hold the rebars in place, and using pre-fabricated mesh or rebar mats as a convenient way to reinforce large areas of concrete. Additionally, epoxy-coated rebars can be used to protect against corrosion and increase the longevity of the reinforced concrete.

- Q: What are the cost implications of using steel rebars in construction?

- The cost implications of using steel rebars in construction can vary depending on several factors. Firstly, the cost of steel rebars themselves will have an impact on the overall construction budget. The price of steel rebars can fluctuate due to factors such as global demand, availability of raw materials, and market conditions. Therefore, the cost of steel rebars can differ from one project to another. Secondly, the quantity of steel rebars required for a construction project will also affect the cost implications. The size, complexity, and load-bearing requirements of the structure will determine the amount of steel rebars needed. As a result, larger and more intricate projects will require a higher quantity of steel rebars, which can increase the overall construction costs. Moreover, the installation and labor costs associated with steel rebars should be considered. Experienced and skilled labor is required to properly install and secure the rebars in place, ensuring structural integrity. The cost of labor can vary depending on the location, availability of skilled workers, and project timeline. Additionally, the equipment and tools necessary for handling and cutting steel rebars may incur additional expenses. Furthermore, the longevity and durability of steel rebars can have long-term cost implications. Steel is known for its strength, resistance to corrosion, and ability to withstand harsh environmental conditions. By using steel rebars, structures can have a longer lifespan and require less maintenance and repairs over time. This can result in significant cost savings in terms of maintenance and replacement expenses. However, it is also important to consider potential cost implications related to sustainability and environmental impact. The production of steel rebars requires substantial energy and resources, which can contribute to carbon emissions and environmental degradation. In some cases, alternative construction materials or methods may be more cost-effective in terms of sustainability and long-term environmental considerations. In summary, the cost implications of using steel rebars in construction depend on factors such as the price of steel, quantity required, labor costs, installation expenses, and long-term durability. While steel rebars offer numerous benefits in terms of strength and longevity, it is crucial to consider the project's specific requirements and balance them with potential economic and sustainability considerations.

- Q: What are the different methods for cutting steel rebars on-site?

- There are several methods available for cutting steel rebars on-site, depending on the specific requirements and limitations of the project. Some of the common methods include: 1. Manual Cutting: This method involves using handheld manual tools such as rebar cutters or bolt cutters to cut through the steel rebars. It is suitable for smaller projects or areas where power tools may not be accessible. 2. Abrasive Cutting: Abrasive cutting, also known as grinding or cut-off saws, utilizes a high-speed rotating disc with abrasive particles to grind through the steel rebars. This method is effective for cutting rebars of various sizes and is commonly used in construction sites. 3. Torch Cutting: Using oxy-fuel or plasma torches, this method involves heating the steel rebars to a high temperature and then cutting through them using the intense heat. Torch cutting is suitable for thicker and larger rebars but requires caution and safety measures due to the open flame involved. 4. Shear Cutting: Shear cutting involves using hydraulic or mechanical shears to cut through the steel rebars. This method is efficient for cutting rebars quickly and accurately, especially for larger projects. 5. Hydraulic Cutting: Hydraulic cutters use hydraulic pumps to generate high pressure, which is then used to power the cutting blade. This method is commonly used for heavy-duty cutting tasks and can cut through thick rebars with ease. 6. Electric Cutting: Electric cutters, such as electric rebar cutters or portable band saws, are powered by electricity and provide a clean and precise cut. They are commonly used in construction sites where power is readily available. It is essential to consider the specific requirements of the project, including the size and thickness of the rebars, available power sources, and safety considerations, when selecting the appropriate method for cutting steel rebars on-site.

Send your message to us

G460B deformed steel bar deformed steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords