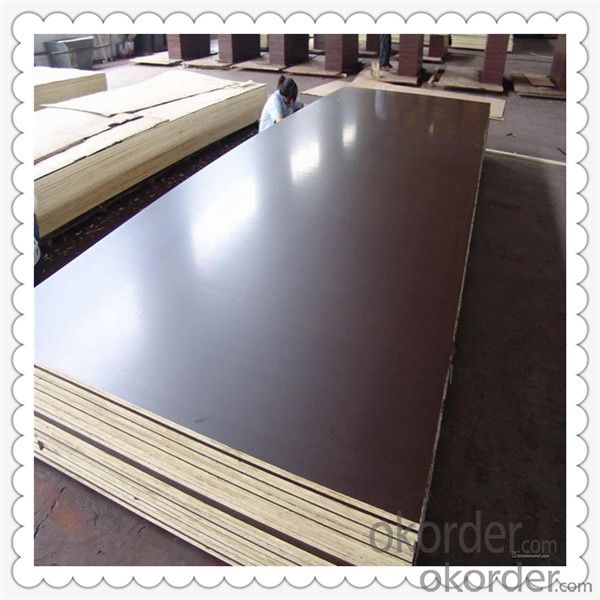

Brown Color Film Faced Plywood with Lowest Price and High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brown Color Film Faced Plywood with Lowest Price and High Quality

Product Description:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Usage: Indoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: Teak

· Face/back: teak, oak, beech, ash walnut, sapele etc

· Thickness: 2.6mm,3.0mm,3.6mm,4.0mm,4.6mm,5.2mm 12mm,9mm,as your request

· Core: poplar, combi, hardwood, MDF

· Glue: melamine: MR, E2,E1

Product Specification:

Name | Fancy Plywood |

Size | 1220mmx2440mm or 915x2135mm |

Thickness | 2.0mm---18mm |

Thickness Tolerance | ±0.2mm to ±0.3mm |

Core | poplar core & harewood core, combi or as agreed. |

Face/Back | Nature ash, Sapeli, Red Oak, White Oak, Teak, steam Beech, Okoume, Cherry, Walnut, |

Glue | WBP, Melamine, E0, E1, E2, MR |

Grade | AAA, AA, A or as agreed. |

Moisture | Below 12% at time of shipment. |

Usage | Decoration, furniture, construction. |

Package | Inter packing: 0.20mm plastic bag. Outer packing: pallets are covered with plywood or carton and then steel for strength. |

Delivery time | 20 days on receipt of deposit or original L/C. |

Min Order | 50 cubic meter |

Payment terms | L/C at sight, T/T30% as deposit, |

Supply ability | 4000 cubic meter/month |

Main market | Middle East, Southeast Asia, East Asia, South Asia Africa etc. |

Packaging & Delivery:

· Inter packing: 0.20mm plastic bag.

· Outer packing: pallets are covered with plywood or carton and then steel for strength

· Delivery Detail: 30 days after receiving LC or deposit

Company Info:

China National Building Material Group Corporation (CNBM for short) was establish in 1984, a Central Enterprise under direct supervision of State- owned Assets Supervision and Administration Commission of the State Council of China.

As of the end of 2000, CNBM has 492 member companies under management around the world, of which 5 were A-share listed holding companies and 2 were H-share listed. CNBM has total assets exceeded RMB 110 billion, and more than 100,000 employees.

CNBM is the largest comprehensive building material industrial group in China that integrates scientific research, manufacturing and logistics into one entity.

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: OKorder Wang Teng color steel production and sales of a variety of color steel plate, Caigang tiles, Caigang rock wool sandwich panels, Caigang polyurethane sandwich panels, Caigang foam sandwich panels, Caigang extruded sandwich panels, color Steel paper honeycomb sandwich panels, galvanized sheet, floor board, Caigang sandwich panels, C steel, color steel activities, and other products.

- OKorder Wang Teng Choi Steel Structure Co., Ltd. specializing in the production of sandwich panels foam sandwich panels Yanmian sandwich panels polyurethane sandwich panels glass wool cotton sandwich panels paper honeycomb sandwich panels aluminum honeycomb sandwich panels phenolic sandwich panels hand sandwich panels stainless steel Sandwich panel sandwich panel offer sandwich panel specifications sandwich board type sandwich panel manufacturer sandwich panel density sandwich panel thickness sandwich panel wholesale sandwich panel sales sandwich panel suppliers - OKorder Wang Teng color steel structure limited the company

- Q: What is the acceptance criteria for rock wool sandwich panels?

- 1) upper and lower surface: the use of galvanized color steel plate, the thickness of 0.4-0.8mm. According to the specific requirements of customers, can also be used galvanized steel or galvanized steel plate. The steel plate is first molded by a molding machine and is compounded with the rock wool factory. ? 2) Yanmian core material: the use of density of 120kg / m yan rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness. ? Wujiang City Linxue purification Choi Board Co., Ltd. is the China Electronics Society Clean Technology Branch members. Commitment to various types of purification decoration, clean air-conditioning works, hydropower engineering facilities supporting the design, installation, commissioning through-train service.

- Q: Cold storage installation sandwich panels need to use sealant? With much more, with polyurethane sealant or silicone glue more?

- Generally with porcelain white neutral silicone

- Q: Color steel sandwich panel wall, you can directly spray really stone paint what is the practice

- According to the following construction methods to achieve good results: 1, in the sandwich panel (plate) on the gap to be caulking. It is recommended to use the home of the heart of the card to worry about toughness to fill the joints, and then paste the seam (master understand). 2, if directly in the sandwich panel (plate) on the batch of putty powder or spray paint really easy to drop off the phenomenon of paint, the first primer, it is recommended to use the home of the board of people worry-free putty scraping again There are), to be dry and then approved scraping putty powder. 3, spray really stone paint.

- Q: Purification workshop manual sandwich board how much money to install a square can do

- Artificial is generally 18 - 30 side of the doors and windows in addition to the general one plus a window plus 80--100 yuan

- Q: What are the types of metal wool wool sandwich panels?

- Mainly Langfang BlueScope, OKorder Kangsai, Guangzhou Xisi Er, three companies are currently the best quality production of rock wool sandwich board company, its price is high level, other manufacturers of rock wool sandwich panels most of the Belong to medium or middle level

- Q: Can Caoyan rock wool sandwich panels be used as permanent construction timber?

- Can not, just take a simple color coated board for a long time will be corrosive

- Q: What is the ESP sandwich panel

- EPS is polystyrene, which is what we call foam board Sandwich refers to the foam as the core material, the external double-sided composite material of other plates. Other plate is generally the majority of color steel plate.

- Q: OKorder where to sell rock wool color plate, rock wool sandwich panels and good quality?

- Prices fluctuate at any time

- Q: Color steel sandwich board surface rust how to do

- The surface rust is because the color plate surface paint off the inside of the steel plate caused by oxidation. General this situation waiting for oxidation rust, perforation. Refurbishment is not impossible, but the cost is high. You can try to wash the rust with acid, Brush paint.

Send your message to us

Brown Color Film Faced Plywood with Lowest Price and High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords