Breathable Membrane for Roofing Construction with UV

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Breathable Membrane for Roofing Construction with UV

Introduction:

Breathable Membrane is a water resistant membrane but with high vapor permeability, use as diffusion open roofing felts under pitched roof tile or vapor permeable barrier house wraps on timber frame walls.

Breather membrane functions as a weather-resistant barrier, preventing rain from getting into the roof or wall assembly while allowing water vapor to pass to the exterior.

Breather membrane may also serve as an air barrier if it is sealed carefully at seams.

Breathable Membrane have good "water resistance", good "water vapor permeability", and good "air barrier properties". Weather Proof House Wrap.

Specification:

Surface mass density | 80 g/m² | ||

Roll size | 1.5m*50m or customized | ||

Vapor permeability | ≥2250 g/m²/24h | ||

Sd value | 0.02 m (-0.005/+0.015) | ||

Water tightness | class W1 | ||

Tensile strength MD/CD | 105/70N/50 mm (+/-20%) | ||

Tearing strength MD/CD | 50/60 N (+/-20%) | ||

Resistance to UV rays | 3 months | ||

Reaction to fire | Class F | ||

Loading quantity | 20’GP | 40’GP | 40’HC |

By bulk (1.5*50) | 1140rolls | 2450rolls | 2700rolls |

With pallets (1.5*50m) | 900rolls | 1954rolls | 2122rolls |

Jumbo rolls (1.5*3500m) | 14rolls | 30rolls | |

Advantages:

1)Excellent performance at water resistance

2)Particular function of water vapor permeability

3)Good performance at UV resistant for 3 months

4)They are much lighter than bitumen felts, suitable for construction in different condition

5)They have excellent tensile and tearing strength

6)100% recyclable

7)Simple installation in new building, re-roofing and refurbishment situations

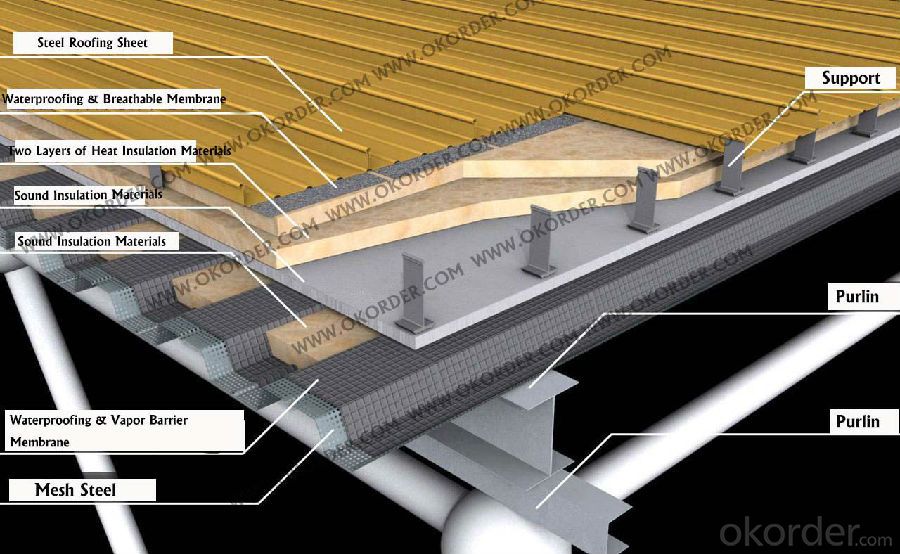

Typical Installation:

Typical Application:

Prodution Packages & Container Loading

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q: What is the car waterproof sticker material?

- B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

- Q: Waterproof mortar expensive or dry mortar expensive

- Dry mortar is usually called hydraulic cement mixed mortar, refers to the dry sieve treatment of aggregate (such as quartz sand), inorganic cementing materials (such as cement) and additives (such as polymers) and so on a certain proportion of physical mixing Into a granular or powdered, in the form of bags or bulk transported to the site, add water, mix directly after the use of materials.

- Q: Roof membrane waterproof construction process, what should be noted that?

- Three do 1 to do concrete or mortar ratio is accurate 2 to do the surface of the second calendering 3 to be fully maintained

- Q: Home improvement waterproofing problem

- 3, waterproof as to do more than 2 centimeters of closed water 24 hours or more closed water test, check whether there is leaking and dampness downstairs phenomenon.

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- As the SBS coil finished with pure asphalt is not the same, the coil includes a variety of surface material weight. The following is the different types and different thickness of the SBS coil unit area weight, due to the need to lap and pave the reinforcement layer, calculate the load in the following unit area weight, the general multiplied by 1.2 coefficient.

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Third, from the indoor water leakage area for waterproof maintenance.

- Q: There is no formaldehyde in the finished putty

- Often people are talking aldehyde color change, because the formaldehyde is very polluted environment contains a lot of carcinogenic substances, so into the wall inside unknowingly become an environmental killer.

- Q: I would like to ask how to do in the warm water above,

- Rough housing or liquid with a good, airtight than the coil is good, all-pervasive, if there is a trachoma in the case of white do not see the white. If the building from the building if the first waterproof, finished product protection is a problem.

- Q: Developers have done waterproof, decoration house also have to do it

- so, in your house When the decoration, or should do a waterproof treatment.

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 4: coating waterproof layer coating evenly, the thickness of the product to meet the technical requirements, the general thickness of not less than 1.5mm not exposed at the end.

Send your message to us

Breathable Membrane for Roofing Construction with UV

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches