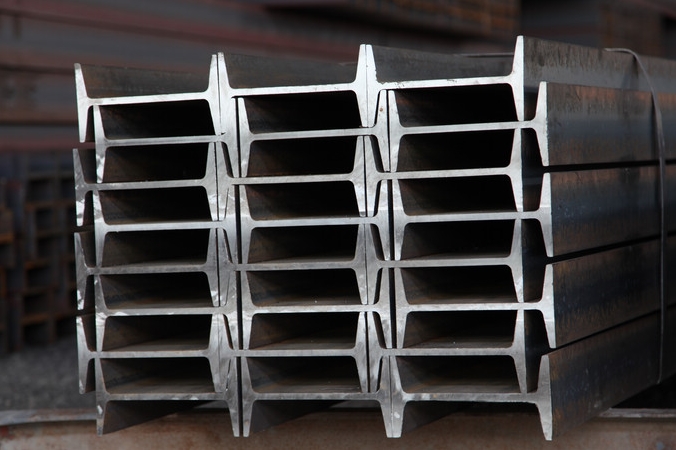

black galvanized steel i beam ipe steel beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact us.

Steel I Beams are widely used throughout the construction industry when supporting heavy loads is required. Commonly termed an “I” Beam because of its shape, beams provide great load bearing support when used horizontally or standing as columns. Available in two configurations, the most popular being the Wide Flange Steel Beam aka H Beam or W Beam with non-tapered flanges. This beam shape has a wider profile for added horizontal strength, making it ideal for skyscrapers or as a house beam, along with bridge beams, trailers, platforms, etc. Standard American Beams, aka Junior Beams or S Beams, have tapered flanges for added strength when your load is concentrated on the flanges, such as machine bases, hoists, cranes or a trolley beam for your garage. Rcjs steel stocks a wide range of steel beam sizes for thousands of applications. Shop online for standard or cut to size lengths at wholesale steel beam prices. We also offer a selection of Galvanized Steel Beams. Just give us a call if you need something special.

- Q: What are the different types of steel connections used for composite I-beams?

- There are several types of steel connections commonly used for composite I-beams, which are engineered to combine the strengths of both steel and concrete in structural applications. These connections ensure the effective transfer of forces between the steel beam and the concrete slab to create a unified and efficient load-bearing system. One type of steel connection used for composite I-beams is the shear stud connection. Shear studs are short, steel bars that are welded to the top flange of the steel beam prior to pouring the concrete slab. The studs act as shear connectors, effectively transferring the shear forces between the steel beam and the concrete slab. This type of connection enhances the composite behavior of the beam by allowing the concrete slab to act as a compression member, increasing the overall strength and rigidity of the system. Another common type of connection is the bolted connection. Bolted connections are typically used in composite I-beams where the steel beam is connected to other steel members or accessories, such as column flanges, bracing, or other beams. These connections involve the use of high-strength bolts and nuts, which are tightened to a specific torque to ensure proper load transfer and structural integrity. Bolted connections provide flexibility in terms of assembly, disassembly, and modification of the structure. Welded connections are also utilized in composite I-beams, particularly in cases where the steel beam needs to be connected to other steel elements. Welding involves the fusion of the steel materials using heat, creating a strong and permanent connection. Welded connections offer high strength and durability, making them suitable for applications where significant loads and forces are involved. Moreover, moment connections are used in composite I-beams to transfer moments or rotational forces between the steel beam and the concrete slab. These connections are often achieved through a combination of shear studs, bolts, and welding. Moment connections enhance the overall behavior of the composite system by allowing it to resist bending moments and provide stability to the structure. In summary, the different types of steel connections used for composite I-beams include shear stud connections, bolted connections, welded connections, and moment connections. Each type of connection serves a specific purpose in ensuring the effective transfer of forces and enhancing the performance of the composite beam system. The selection of the appropriate connection depends on the specific design requirements, loads, and structural considerations of the project.

- Q: Can steel I-beams be used in temporary or relocatable structures?

- Yes, steel I-beams can be used in temporary or relocatable structures. Steel I-beams are commonly used in construction due to their strength, durability, and versatility. They can be easily assembled and disassembled, making them suitable for temporary or relocatable structures such as portable buildings, temporary bridges, or event structures.

- Q: Can steel I-beams be used in water treatment or wastewater facilities?

- Yes, steel I-beams can be used in water treatment or wastewater facilities. They are commonly used for structural support in the construction of tanks, channels, and other infrastructure in these facilities. The corrosion-resistant properties of certain types of steel make them suitable for handling water and wastewater, ensuring durability and longevity in such environments.

- Q: How are steel I-beams installed during construction?

- Steel I-beams are typically installed during construction by first preparing the foundation or structural supports. The I-beams are then lifted into place using cranes or other heavy machinery. They are aligned and secured to the supports using bolts or welding. Additional components, such as columns or cross braces, may be added to enhance stability and structural integrity.

- Q: Do steel I-beams require any special maintenance or care?

- Special maintenance and care are necessary for steel I-beams to ensure their longevity and performance. Consider the following guidelines: 1. Conduct Regular Inspections: Trained professionals should regularly inspect steel I-beams to identify signs of corrosion, cracks, or structural damage. Based on their assessment, appropriate maintenance actions can be recommended. 2. Ensure Proper Cleaning: Periodic cleaning of steel I-beams is vital to remove dirt, debris, and corrosive substances that may accumulate on their surfaces. This practice prevents corrosion and maintains the beams' structural integrity. 3. Prevent Rust: Steel beams are prone to rust, especially when exposed to moisture or harsh environmental conditions. Applying a protective coating, such as paint or a specialized rust inhibitor, can prevent corrosion and prolong the beams' lifespan. 4. Prompt Repairs: If any damage or deterioration is detected during inspections, immediate repairs should be carried out. This may involve welding, replacing damaged sections, or reinforcing weak areas to restore the beams' structural integrity. 5. Monitor Loads: Regularly monitor steel I-beams for excessive loads or changes in load distribution. Overloading can cause stress, leading to deformation or failure. Monitoring ensures that the beams are not subjected to loads beyond their design capacity. 6. Seek Professional Guidance: Consult a structural engineer or qualified professional for specific maintenance procedures and schedules for steel I-beams. They can offer expert advice and recommend suitable maintenance practices based on the application and environmental conditions. By adhering to these maintenance practices, steel I-beams can remain in excellent condition and provide reliable structural support for an extended period.

- Q: What are the common types of connections for steel I-beams in moment-resisting frames?

- The common types of connections for steel I-beams in moment-resisting frames include bolted connections, welded connections, and hybrid connections. Bolted connections involve using bolts and nuts to join the steel I-beams to other structural components such as columns and beams. These connections provide flexibility and ease of installation and can be easily disassembled if needed. Bolted connections also allow for adjustments during construction or future modifications. Welded connections involve permanently joining the steel I-beams to other components using welding techniques. This type of connection offers high strength and rigidity, ensuring a robust and stable frame. Welded connections are commonly used in moment-resisting frames due to their ability to transfer large forces and moments between structural members. Hybrid connections combine both bolted and welded connections. This type of connection typically involves using bolts for the primary connection and welding for additional reinforcement. Hybrid connections offer the advantages of both bolted and welded connections, such as ease of installation and high strength. The choice of connection type depends on various factors, including the design requirements, load capacity, construction methods, and cost considerations. Structural engineers carefully analyze these factors to determine the most suitable connection type for steel I-beams in moment-resisting frames, ensuring the overall stability and performance of the structure.

- Q: How is I-beam connected?

- Connections between steel column and steel beam:1. The steel column is connected with the steel beam and the 2 stiffened plate is arranged in the direction of the steel beam. The distance between the stiffener and the steel beam is the height of the stiffener;2 、 steel column stiffener plate welding plate (open bolt hole), connecting plate height = steel beam web height;3. The connection between the steel beam and the steel column is bolted.

- Q: Which bearing capacity is stronger?

- Both I-beam and channel steel should be used as beam members, and the bending moment can be greater than that of other kinds of materials under two weight conditions. Because when it is used as a beam, the stress produced by the bending moment is X type, the stress at the top and the lower part of the beam is maximum, and the middle part is smaller, while the I-beam and the channel steel are both the top and the bottom.

- Q: How do steel I-beams compare to reinforced concrete beams in terms of cost and performance?

- Steel I-beams typically have a lower initial cost compared to reinforced concrete beams due to the more efficient manufacturing process. However, reinforced concrete beams offer longer-term cost savings as they require less maintenance and have a longer lifespan. In terms of performance, steel I-beams provide superior strength-to-weight ratio, allowing for longer spans and more flexibility in design. On the other hand, reinforced concrete beams offer better fire resistance and soundproofing properties. Ultimately, the choice between steel I-beams and reinforced concrete beams depends on the specific project requirements, budget, and desired performance characteristics.

- Q: Can steel I-beams be used for educational institutions?

- Yes, steel I-beams can be used for educational institutions. Steel I-beams are commonly used in construction due to their high strength and load-bearing capabilities. They can provide structural support for buildings, including educational institutions, ensuring safety and stability. Additionally, steel I-beams offer design flexibility, allowing for spacious and open interior spaces within educational buildings.

Send your message to us

black galvanized steel i beam ipe steel beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products