Black Aluminum Strips PVDF Roller Shutter Gutter Roof ACP Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

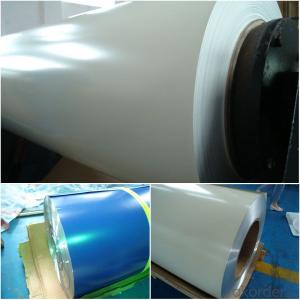

pe pvdf roller shutter gutter roof acp prepainted aluminum coil, painted aluminum sheet, painted aluminum coil

1. color coated aluminium coil Brief Introduction:

| Aluminum Alloy: | AA1100,1050,1060,3003,3004,3005,3103,3105,5005,5052,5083,5754,6061,8011,O,O-H112,ETC. |

| Temper: | O,H16,H18,H22,H24,H26,H28 |

| Aluminum Alloy Thickness: | 0.08mm~1.2mm(0.08,0.18,0.28,0.38,0.48,0.6,0.8,1 mm) |

| (0.1,0.15,0.25,0.35,0.45 mm) | |

| Coil Width: | 30~1520mm china price color coated aluminium coil |

| Core Diameter: | 150/405/505mm |

| Coil Weight: | 1~2.5tons each coil for 3003 colorful aluminium coil for acp |

| Coating Type: | PE,PVDF,back coatting,ACRYLIC,feve |

| Surface Type: | Smooth,Embossed,mill finish,coated,brushed,etc. |

| Glossness: | 10-90%(EN ISO-2813:1994) |

| Coating Thickness: | PE:more than 18 +-1micron |

| PVDF:more than 25+-1micron | |

| Back Coating:8~10+-1micron | |

| Coating Color: | Color A:pure white, ivory, white matte,yellow white,opal,light gray, aluminum natural color etc. |

| Color B:blue,yellow,gray,black,dark gray etc. | |

| Color C:white silver gray,flash silver,champagne etc. | |

| Color D:violet,pure orange,orange,bright red,china red,dark blue,brown,green,laker blue,flash gold yellow etc. | |

| Paint Hardness: | More than 2H |

| Coating Adhesion: | 5J(EN ISO-2409:1994) |

| Impact Resistance: | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility(T-bend): | <2T |

| MEK resistance: | More than 100 |

| Salt Fog Resistance(H): | ≥500 |

| Advantage: | 1.High temperature resistant 3003 colorful aluminium coil for acp |

| 2.Weathering resistant | |

| 3.Scrubbing resistant | |

| 4.Sound insulation | |

| 5.Acid or alkali proof,Fireproof | |

| 6.Light weight material is easy to construct and install | |

| Packing Details: | Five-layer carton,strong polar fumigation wooden pallet,steel belt fastened outside,worthy shipping by sea. |

| Coating Aluminum Standard: | Chemical Composite:GB/T 3190-2008,JIS,EN,ASTM,Mechanical Property: GB/T 3880-2006, JIS, EN, ASTM |

| Certification: | ROHS,SGS,FDA,ISO9001:2008,GB/T 28001-2001,FORM A/E/F or CO,Mill Test Report |

| Application: | acp,aluminum composite panel,roof,gutter,ceiling,facade,wall cladding,gutter,aluminum honeycomb panel,roller shutter,rolling shutter,truck body,rolling shutter door,etc. |

2. color coated aluminium coil features:

1.Morn than 13 years experiences specializing in producing and servicing coated aluminum coil with pe,pvdf,back coating.

2.Famous brands Serving:reynobond,Alpolic,Alstone,Alstrong,alucoworld,indobond,etc.

3.More than 10 years joining cooperation and adopting famous-brand aluminum alloy from Southwest,Shandong Fuhai aluminum,etc,stabling aluminum alloy suppling in various kinds aluminium alloy with aluminum models of AA1100,3003,3005,1050,1060,1070,5052,etc.

4.More than 10 years joining cooperation and adopting famous-brand paints from Sweden Becker,and American PPG,which jointly issued 20years warranty for color coil coated,such as High temperature resistant,Excellent weather-proof durability,Anti-ultraviolet.

5.More than 12 years experiences in dealing with quality issues which guarantee for high quality and stable coated aluminum coil suppling.

- Q: What benefits are associated with the use of aluminum strips on the exterior walls of buildings?

- <p>Aluminum strips for exterior walls offer several advantages, including durability, resistance to corrosion and weathering, and low maintenance requirements. They are lightweight, which can reduce the load on the building structure. Aluminum strips also provide excellent heat insulation properties, contributing to energy efficiency. Additionally, they can be easily shaped and bent, allowing for versatile and modern architectural designs. The recyclability of aluminum makes it an environmentally friendly choice, and its non-combustible nature enhances safety in construction.</p>

- Q: This question asks for a list of various types of aluminum components used in the automotive industry.

- <p>Aluminum is widely used in the automotive industry due to its lightweight and high strength. Different types of automotive aluminum parts include engine components such as cylinder heads and blocks, transmission housings, suspension parts like control arms and knuckles, wheels and rims, body panels, and doors. Other applications include heat exchangers, radiators, and various brackets and structural components. The use of aluminum can significantly reduce the weight of vehicles, improving fuel efficiency and performance.</p>

- Q: This question asks for an explanation of the various types of aluminum cladding materials used in construction.

- <p>Aluminum cladding is a popular choice in construction for its durability and low maintenance. The different types include: 1. Aluminum Composite Material (ACM), which is lightweight and consists of two thin aluminum sheets with a non-aluminum core. 2. Aluminum Plate, a thicker and more rigid material used for structural applications. 3. Aluminum Extrusions, which are formed by pushing aluminum through a die to create specific shapes and profiles. 4. Aluminum Coil Coating, where aluminum coils are coated with a protective layer and used for roofing and siding. 5. Anodized Aluminum, which undergoes an electrochemical process to increase its resistance to wear and corrosion. Each type has specific applications and properties, making them suitable for different construction projects.</p>

- Q: What are the unique production techniques employed in the manufacturing of high-quality aluminum strips?

- <p>High-quality aluminum strips are produced using specialized manufacturing methods to ensure precision and consistency. Key methods include precision casting to achieve uniform thickness, continuous casting for improved material properties, and cold rolling to refine the strip's dimensions and surface finish. Annealing processes are also crucial for enhancing ductility and reducing hardness. Additionally, advanced surface treatments like anodizing or coating may be applied to improve corrosion resistance and aesthetics. Quality control measures such as strict dimensional checks and surface inspections are integral to ensuring the strips meet stringent quality standards.</p>

- Q: What distinguishes extruded aluminum strips from rolled ones in terms of manufacturing process and properties?

- <p>Extruded aluminum strips are formed by forcing aluminum through a die, creating a specific profile or shape. This process results in a more uniform cross-section and can produce complex profiles. Extruded strips are stronger and have better dimensional stability due to the grain flow being aligned with the direction of the extrusion. Rolled aluminum strips, on the other hand, are created by passing aluminum between rollers to achieve the desired thickness and width. This method is more suitable for producing thin, wide strips and is less costly for simpler profiles. Rolled strips may have some residual stresses and are not as strong as extruded ones, but they are more flexible and can be used in applications requiring formability.</p>

- Q: What are the environmentally friendly options for aluminum strips?

- <p>Yes, there are environmentally friendly types of aluminum strips. Recycled aluminum strips are more eco-friendly as they require significantly less energy to produce compared to virgin aluminum. Additionally, using aluminum strips with a high recycled content reduces waste and conserves natural resources. Another option is to look for aluminum strips that are produced using renewable energy sources, which further reduces their carbon footprint. Lastly, choosing aluminum strips with a lower coating or treatment that is biodegradable or has a lower environmental impact can also contribute to their environmental friendliness.</p>

- Q: The user is inquiring if it's possible to utilize recycled aluminum for their roofing project.

- <p>Yes, you can use recycled aluminum for your roofing project. Recycled aluminum is not only environmentally friendly but also cost-effective. It retains the same strength and durability as new aluminum, making it an excellent choice for roofing. It's lightweight, resistant to corrosion, and can be easily shaped and installed. Additionally, using recycled aluminum helps reduce waste and conserves natural resources. However, it's important to ensure that the recycled material meets quality standards and is sourced from a reputable supplier to guarantee its performance and longevity.</p>

- Q: Is it possible to recycle aluminum strips?

- <p>Yes, aluminum strips can be recycled. Recycling aluminum is a highly efficient process that conserves resources and energy. Aluminum is infinitely recyclable without losing its properties, making it an environmentally friendly choice. The recycling process involves melting the aluminum, which requires significantly less energy compared to producing aluminum from raw materials. This not only reduces waste but also lowers greenhouse gas emissions. Proper recycling of aluminum strips helps in conserving natural resources and reducing the environmental impact of aluminum production.</p>

- Q: Is it possible to utilize recycled aluminum in the production of new solar panels or reflectors?

- <p>Yes, recycled aluminum can be used to make new solar panels or reflectors. Aluminum is a valuable material in solar panel construction, particularly for framing and mounting structures. It is lightweight, durable, and has good thermal conductivity. Recycling aluminum reduces energy consumption and environmental impact compared to mining and processing new aluminum. Recycled aluminum can be melted down and reformed into new shapes, making it suitable for manufacturing solar panel components. However, the quality of recycled aluminum must meet specific standards to ensure the structural integrity and performance of the solar panels or reflectors.</p>

- Q: This question asks for the distinction between aluminum as a material and aluminum strips as a specific form of that material.

- <p>Aluminum is a chemical element and a lightweight, soft, silvery-white, nonmagnetic metal in the boron group. It is highly malleable, ductile, and has a strong resistance to corrosion. Aluminum strips, on the other hand, are a specific form of aluminum that has been processed into thin, flat, elongated pieces. These strips are used in various applications such as packaging, construction, and manufacturing due to their strength, flexibility, and conductivity. The main difference lies in their physical form and usage; aluminum is the raw material, while aluminum strips are a processed product.</p>

Send your message to us

Black Aluminum Strips PVDF Roller Shutter Gutter Roof ACP Prepainted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords