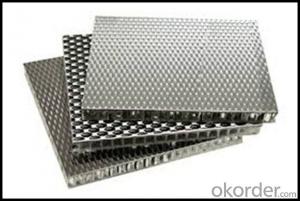

Aluminum Transition Strips for Flooring - Sandwich Panel from High-Quality Aluminum Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum panel is easy to processing, forming a good material.But also in the pursuit of efficiency, strive for the excellent product of time, it can shorten the construction period, reduce the cost.Aluminous model board can be cutting, cutting, notching, band saw, drilling, machining head, can also be cold bending, cold, cold rolling, can also be riveting, screw connection or agglutination adhesive, etc.

1)Main features of the PE Composite with Aluminium Foil and Paper:

. Flexible and durable

. Light and easy to transport

. Fast delivery

. Item shipped from Dubai warehouse

2)PE Composite with Aluminium Foil and Paper Images:

3)PE Composite with Aluminium Foil and Paper Specification:

Thinkness: 0.009-0.05mm

Dimension:82*76.2*1000mm

Weight : 10kg

Color: transparent

4)FAQ of PE Composite with Aluminium Foil and Paper:

1. 30% T/T advance , then balance before shipment or against BL copy. Or 30% L/C payment, balanced duaring 30-60 days.

2. The other specific issues can be negociated.

3. Any problem, feel free to contact us. We will reply as soon as possible.

- Q: Is it good to drive a wheeled excavator or an aluminum belt?

- Wheeled as if driving a car, the aluminum belt seems to open tanks.

- Q: This question asks for the cost of aluminum strip roofing, which is a type of metal roofing material.

- <p>The cost of aluminum strip roofing can vary significantly based on factors such as the quality of the aluminum, the complexity of the installation, and regional pricing. On average, the cost of aluminum strip roofing ranges from $6 to $12 per square foot for the materials alone. This does not include labor costs, which can add another $3 to $10 per square foot. It's important to get quotes from multiple contractors in your area to get an accurate estimate for your specific project. Prices can fluctuate, so it's best to check current market rates for the most up-to-date information.</p>

- Q: Is it possible to utilize aluminum strips instead of conventional siding materials in areas with high temperatures?

- <p>Yes, aluminum strips can be used to replace traditional siding materials in hot climates. Aluminum is a lightweight, durable, and corrosion-resistant material that can withstand high temperatures. It reflects heat, reducing the amount of heat absorbed by the building, making it a suitable choice for hot climates. Additionally, aluminum siding is low maintenance and can be easily painted or finished to match the desired aesthetic. However, it's important to consider factors such as insulation properties and potential for condensation, as aluminum may not insulate as well as some other materials.</p>

- Q: Is it possible to substitute metal sheets for asphalt shingles on a roof?

- <p>Yes, you can use metal sheets to replace asphalt shingles on your roof. Metal roofing is a durable and weather-resistant alternative to asphalt shingles. It offers benefits such as longevity, energy efficiency, and low maintenance. However, it's essential to consider the weight of metal sheets compared to shingles, as it may require structural reinforcement. Additionally, proper installation by a professional is crucial to ensure the roof's integrity and to maximize the benefits of metal roofing.</p>

- Q: This question asks about the expected duration that aluminum strip siding can last on a building after it has been installed.

- <p>The lifespan of an aluminum strip siding installation can vary, but on average, it is estimated to last between 20 to 40 years. This range is influenced by factors such as the quality of materials, installation techniques, and the environmental conditions the siding is exposed to. Proper maintenance, such as regular cleaning and inspection for damage, can help extend the life of aluminum siding. However, it's important to note that with advancements in materials and coatings, some modern aluminum siding products may offer even longer lifespans.</p>

- Q: What are the cost differences between aluminum and aluminum strips?

- <p>Aluminum and aluminum strips are both made from the same base material, but their costs can differ due to several factors. Aluminum strips are typically more expensive than bulk aluminum due to the additional processing and manufacturing steps involved in creating them. These steps include rolling, cutting, and sometimes surface treatments, which add to the cost. Additionally, aluminum strips often have tighter tolerances and specific dimensions, which can also increase their price. However, the exact cost difference can vary based on factors such as market prices for aluminum, the complexity of the strip's specifications, and the quantity purchased.</p>

- Q: This question asks for a comparison between standard aluminum strips and custom-made aluminum strips, highlighting their differences.

- <p>Standard aluminum strips are mass-produced with fixed dimensions and specifications, making them readily available and generally more affordable. They are suitable for common applications where specific requirements are not needed. On the other hand, custom-made aluminum strips are manufactured according to specific customer requirements, including size, shape, thickness, and alloy type. This customization allows for unique applications and better performance in specialized environments but may come at a higher cost and with longer lead times due to the bespoke manufacturing process.</p>

- Q: What characteristics of aluminum strips make them an ideal material for roofing purposes?

- <p>Aluminum strips are suitable for roofing due to their lightweight nature, which reduces structural load. They offer excellent corrosion resistance, protecting against rust and decay, and are highly durable, maintaining their integrity for decades. Aluminum's malleability allows for easy shaping into various profiles, enhancing design flexibility. Additionally, aluminum strips reflect heat well, reducing energy consumption for cooling, and they are recyclable, contributing to environmental sustainability.</p>

- Q: This question asks for a method to accurately measure the length of aluminum strips.

- <p>To accurately measure the length of aluminum strips, use a digital caliper or a steel ruler with a high degree of precision. Place the strip on a flat surface and align the measuring tool with one end of the strip. Ensure the strip is straight and not bent. Gently extend the measuring tool along the strip until you reach the other end. Take note of the measurement displayed. For best accuracy, measure from the same point on both ends of the strip and repeat the process a few times to account for any potential parallax error. If the strip is very long, consider using a measuring tape with a fine scale. Always check your measuring tool for any wear or damage that could affect accuracy.</p>

- Q: The role of aluminum strip in tanks

- The utility model can smoothly, rapidly and safely pass through various complicated traffic conditions, and because the ground area is large, the passing capacity of the tank on the soft and muddy road is increased, and the subsidence amount is reduced.

Send your message to us

Aluminum Transition Strips for Flooring - Sandwich Panel from High-Quality Aluminum Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords