Black Aluminum Diamond Plate Sheets - Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

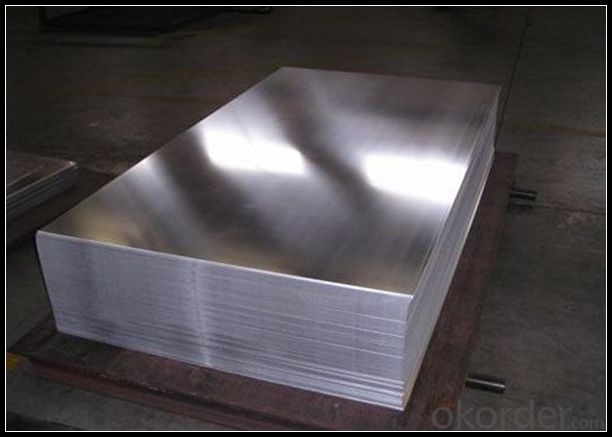

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

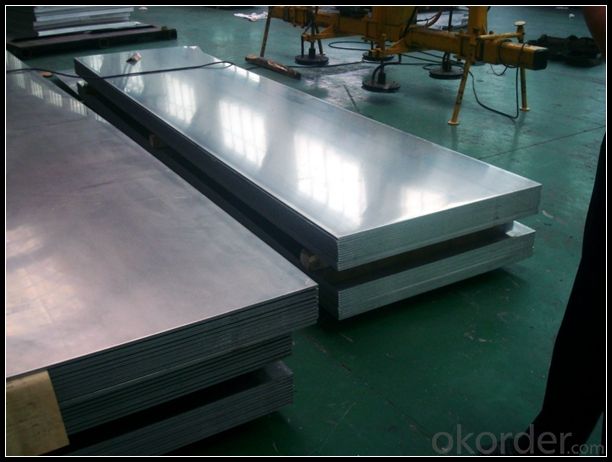

5. Image of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

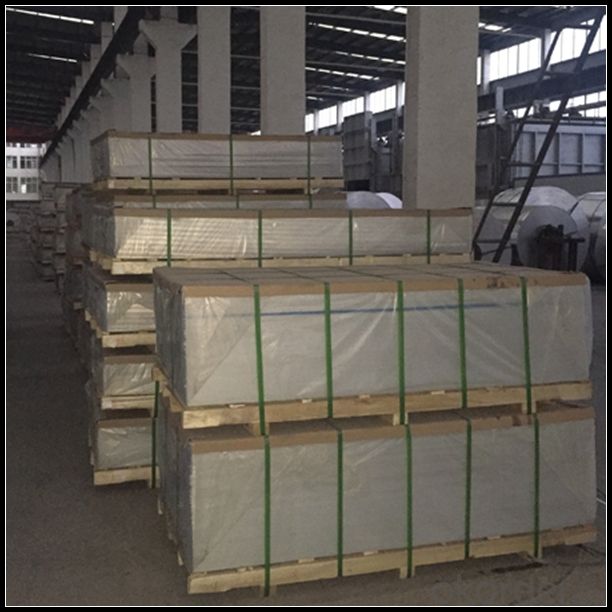

6. Package and shipping of Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different joining methods for aluminum sheets?

- There are several joining methods for aluminum sheets, including welding, adhesive bonding, mechanical fastening, and soldering.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, as long as proper techniques such as annealing and using appropriate tooling are employed.

- Q: How would you write the formula for aluminum sulfate and calcium chloride?

- Aluminium sulfate: Molecular formula Al2(SO4)3·16H2O Calcium chloride: Molecular formula CaCl2

- Q: 3mm heavy aluminum plate, multiple cubic meters per cubic meter?

- So the theoretical weight should be about two and a half tons of one cubic meter.

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, aluminum sheets are available in different finishes such as brushed and polished.

- Q: How are the aluminum plates cut?

- Cutting machine or plasma cutting machine, laser cutting, or electric saw. Generally thin aluminum (below 0.5mm) can be cut with a blade.

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, making it easier to install and reducing the load on the structure of the building. Secondly, aluminum is highly durable and resistant to corrosion, which means it can withstand harsh weather conditions, such as heavy rain, snow, and UV radiation. Additionally, aluminum is non-combustible, making it a safe choice for roofing. Furthermore, aluminum is an environmentally friendly material as it is 100% recyclable, reducing its impact on the environment. Overall, aluminum sheet is a reliable and efficient option for roofing applications.

- Q: Are the aluminum sheets suitable for outdoor applications?

- Indeed, aluminum sheets prove to be fitting for outdoor applications. Renowned for its remarkable resistance to corrosion, aluminum emerges as a prime selection for outdoor utilization. Its immunity to rust and deterioration in the presence of moisture or harsh weather conditions solidifies its status as an ideal candidate. Moreover, aluminum sheets possess the advantageous combination of being lightweight, yet sturdy and long-lasting, rendering them appropriate for an assortment of outdoor applications such as roofing, siding, gutters, and outdoor signage. Additionally, they demonstrate ease of maintenance and can be adorned with paint or protective coatings to bolster their aesthetic appeal and fortify their defense against the elements. All in all, aluminum sheets establish themselves as a dependable and adaptable choice for outdoor applications.

- Q: How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets generally exhibit good creep resistance, especially when compared to other metals. Aluminum has a low melting point and high thermal conductivity, which helps in reducing creep deformation. It also has a fine-grained microstructure that enhances its resistance to creep. However, it is important to note that the creep resistance of aluminum sheets can be affected by factors such as temperature, load, and alloy composition.

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

Black Aluminum Diamond Plate Sheets - Mill Finish Aluminium Sheet Alloy AA3003 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords