Embedment Length of Geogrids Mse Walls - Bitumen Coated Black Polyester Geogrid for Road Construction Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

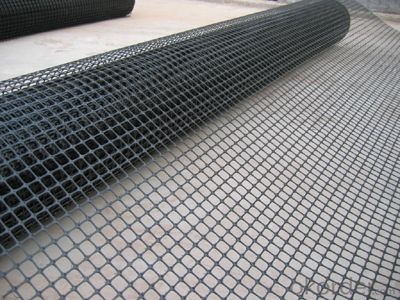

Bitumen Coated Black Polyester Geogrid for Road Construction Use Description

The polyester geogrid selects the excel in synthetic fiber as the material, uses the warp knitting oriented structure, latitude and longitude in the fabric to the yarn between not curving condition, the intersection unifies mutually with the excel in textile fiber filament bundle, forms the reliable combing site, displays its mechanical properties fully.

Bitumen Coated Black Polyester Geogrid for Road Construction Use Overall features & benefits

High tensile strength

High-intensity, High-volume, low creep,

Anti-aging and anti- brittle fracture.

Bitumen Coated Black Polyester Geogrid for Road Construction Use Product Function

1.The soft soil roadbeds of road, railway and other municipal roads are reinforced which can effectively improve the strength of subgrade, delaying reflection cracks in the road;

2.Reinforcement, segregation of the dam and river in water conservancy project reinforce the soft soil base, strengthen their protection and improve the bearing capacity and stability of the foundation;

3.Reinforcement the embankment slope, relating walls reinforced to enhance the overall strength.

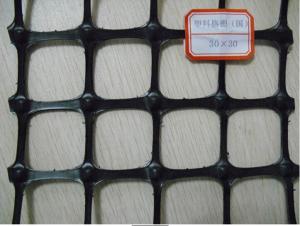

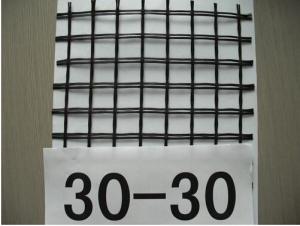

Bitumen Coated Black Polyester Geogrid for Road Construction Use Specification

Tensile Strength: 20, 30,40,50,80,100 120KN/M

Width: 1-6M Length: 50-100 M

We have a good container loading experience and good sell to Russian, Japan, Korea, Vietnam, Thailand, and New Zealand. Any question, warmly welcome to us.

Bitumen Coated Black Polyester Geogrid for Road Construction Use Application

Each kind of high-grade road, railroad’s soft roadbed enhancement isolation different base earth material

The river bank, the slope of embankment strengthen stably

Each kind of ground strengthens stably

Strengthen the bridge connection surface

Bitumen Coated Black Polyester Geogrid for Road Construction Use Packaging & Delivery

| Packaging Details: | each roll with two woven bags; or by pallet |

| Delivery Detail: | 20 Days after receiving your deposit |

F&Q

1 How about the delivery time? Lead time since receipt of 30% T/T deposit payment: 3 weeks.2 What kind of payments does jenor support? T/T 3

What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4

How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5

Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6

Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their stability, reducing rutting and cracking, and increasing their overall lifespan. They act as a reinforcement layer within the pavement structure, distributing and transferring the load more efficiently. This helps to minimize pavement deformations and increase resistance to fatigue and shear stresses. Geogrids also restrain the lateral movement of aggregate particles, preventing their displacement and improving the pavement's resistance to lateral spreading and cracking.

- Q: Can geogrids be used in mining applications?

- Yes, geogrids can be used in mining applications. Geogrids are a type of geosynthetic material that are commonly used in civil engineering and construction projects to reinforce soil and provide stability. In mining applications, geogrids can be used to strengthen and stabilize the ground, prevent soil erosion, and provide support to mining infrastructure such as haul roads and tailings dams. By improving the structural integrity of the ground, geogrids can contribute to safer and more efficient mining operations.

- Q: How do geogrids reduce the amount of fill required for construction?

- Geogrids reduce the amount of fill required for construction by providing reinforcement and stabilization to the soil, allowing for the use of less fill material. They distribute the load more evenly, improving the soil's strength and preventing excessive settlement, which ultimately reduces the amount of fill needed for a stable foundation.

- Q: What is the vertical spacing of Geogrid

- Geogrid generally by horizontal and vertical staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Q: Can geogrids be used in reinforcement of embankments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of embankments on collapsible soils. Geogrids are a type of geosynthetic material that can provide structural stability and improve the overall strength of embankments. They are commonly used to distribute loads, reduce lateral spreading, and prevent soil erosion. When used in conjunction with proper engineering techniques, geogrids can effectively reinforce embankments on collapsible soils and mitigate potential issues related to soil collapse.

- Q: What is the effect of installation spacing on geogrid behavior?

- The effect of installation spacing on geogrid behavior is that it can impact the overall stability and strength of the geogrid system. Proper spacing ensures that the geogrids are installed at the correct intervals, allowing them to distribute the load evenly and provide effective reinforcement. Incorrect spacing can lead to inadequate reinforcement, reduced performance, and potential failure of the geogrid system.

- Q: Geogrid nailed pictures and size

- U studs for the geogrid? You are ready to do the sale of finished products, or on the site directly on the grid?

- Q: What are the design considerations for geogrid reinforcement?

- Some design considerations for geogrid reinforcement include the type and strength of the geogrid material, the required level of soil stabilization, the anticipated loads and stresses on the reinforced soil structure, and the desired lifespan of the structure. Other factors to consider include soil characteristics, installation and construction procedures, and environmental conditions. Additionally, the design should account for factors such as slope stability, drainage, and potential settlement.

- Q: What is the lifespan of geogrids?

- The lifespan of geogrids can vary depending on several factors such as the quality of the material, installation techniques, and the environmental conditions they are exposed to. However, on average, geogrids are designed to have a lifespan of around 20 to 50 years.

- Q: Can geogrids be used for reinforcement in asphalt overlays?

- Yes, geogrids can be used for reinforcement in asphalt overlays. They are commonly used to improve the structural integrity and durability of asphalt overlays by providing additional support and reducing the potential for cracking and rutting. Geogrids can help distribute the load more evenly, increase the tensile strength of the pavement, and enhance long-term performance.

Send your message to us

Embedment Length of Geogrids Mse Walls - Bitumen Coated Black Polyester Geogrid for Road Construction Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords