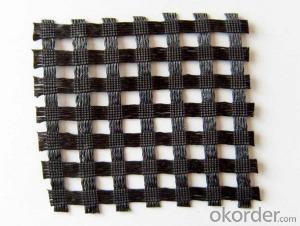

Biaxial Polypropylene Geogrid Geocells for Road Construction in South Africa

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Uniaxial geogrid Product Profile

25-25KN,30-30KN,50-50KN,80-80KN,100-100KN,120-120KN,150-150KN,200-200KN

Width≤6m; Length 50m or as requested

PP Uniaxial geogrid Product Features

1. In high tensile strength

2. Low elongation

3. Anti-erosion, anti-aging

4. Light weight, structural uniformity, easy for construction

5. Flame retardant, anti-static, good overall performance, easy for mechanized operation

6. Good affinity with base materials

PP Uniaxial geogrid Product Specifications

Speification | Unit | 35 | 50 | 80 | 110 | 150 | 200 |

Width | m | 1 or 1.1 or 2.5 or 3 | |||||

Tensile strength | kN/m | 35 | 50 | 80 | 110 | 150 | 200 |

Elongation | % | 10 | 10 | 10 | 10 | 10 | 10 |

Tensile strength at 2% strain | kN/m | 10 | 12 | 26 | 32 | 42 | 56 |

Tensile strength at 5% strain | kN/m | 22 | 28 | 48 | 64 | 84 | 112 |

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: What are the advantages of using geogrids in construction projects?

- Geogrids offer several advantages in construction projects. Firstly, they provide reinforcement to the soil, increasing its stability and load-bearing capacity. This helps to prevent soil erosion, slope failures, and settlement issues. Secondly, geogrids are cost-effective as they reduce the need for extensive excavation and the use of additional materials. They also facilitate faster construction time as they can be easily installed. Additionally, geogrids are durable and resistant to environmental degradation, ensuring long-term performance and reduced maintenance. Overall, the use of geogrids in construction projects leads to improved safety, enhanced structural integrity, and cost savings.

- Q: Are geogrids fire-resistant?

- No, geogrids are not typically fire-resistant.

- Q: Can geogrids be used in soil reinforcement for oil and gas pipeline projects?

- Yes, geogrids can be used in soil reinforcement for oil and gas pipeline projects. Geogrids are often employed in this context to provide stabilization and reinforcement to the soil, improving its load-bearing capacity and preventing soil erosion. This helps ensure the integrity and longevity of the pipeline system, making geogrids a valuable solution for soil reinforcement in oil and gas pipeline projects.

- Q: What is the distance between the waterproof plate and the top of the tunnel? What are the relevant provisions of this specification?

- The main production and operation of a variety of plastic geogrid, steel plastic composite geogrid, fiberglass geogrid, warp knitted polyester geogrid

- Q: Polypropylene geogrid

- You said the polypropylene geogrid, generally only two-way plastic geogrid and one-way plastic geogrid is polypropylene material

- Q: Can geogrids be used in coastal protection projects?

- Yes, geogrids can be used in coastal protection projects. Geogrids are often used to stabilize soil, reinforce slopes, and prevent erosion. In coastal areas, they can be used to strengthen the stability of embankments, sea walls, and revetments, providing long-term protection against wave action and tidal forces.

- Q: How do geogrids improve the performance of geosynthetic encased columns?

- Geogrids improve the performance of geosynthetic encased columns by enhancing their load-bearing capacity, increasing their stability, and reducing settlement. Geogrids act as reinforcing elements within the column, distributing the applied loads more efficiently and preventing lateral spreading. This reinforcement enhances the overall strength and stiffness of the column, enabling it to support heavier loads and resist deformation, settling, and lateral movement. Additionally, geogrids improve the long-term performance of the columns by reducing the potential for differential settlement, ensuring more uniform load distribution, and increasing the overall durability and longevity of the structure.

- Q: Can geogrids be used in reinforcement of gabion walls?

- Yes, geogrids can be used in the reinforcement of gabion walls. Geogrids are commonly used to enhance the stability and strength of gabion structures by providing additional tensile strength and preventing soil erosion. This reinforcement technique helps to increase the overall structural integrity and durability of gabion walls.

- Q: How do geogrids improve the performance of geotextile-reinforced slopes?

- Geogrids improve the performance of geotextile-reinforced slopes by providing additional tensile strength and stability. They enhance the overall structural integrity of the slope, preventing soil erosion and reducing the risk of slope failure. The geogrids act as a reinforcement layer, distributing the lateral forces and increasing the load-bearing capacity of the slope. This improves its overall performance and longevity, making it more resistant to external factors such as heavy rainfall or seismic activity.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials made from polymers, typically high-density polyethylene (HDPE) or polyester, that possess a unique set of properties and characteristics. These include high tensile strength, low elongation, and excellent resistance to chemical degradation and biological attack. Geogrids also have a high modulus of elasticity, which allows them to distribute stress and improve the load-bearing capacity of soils and aggregates. They are typically lightweight and easy to handle, making them convenient for construction applications. Geogrids exhibit excellent dimensional stability and resistance to creep, ensuring their long-term effectiveness. They are also resistant to UV degradation and have a long design life. Overall, geogrids are versatile materials that provide reinforcement, stabilization, and confinement in various civil engineering projects, such as road construction, slope stabilization, and erosion control.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Biaxial Polypropylene Geogrid Geocells for Road Construction in South Africa

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords