Biaxial High Tensile Strength Warp Knitted Geogrids for Tree Protection

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

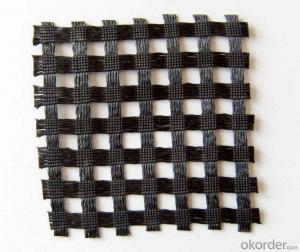

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

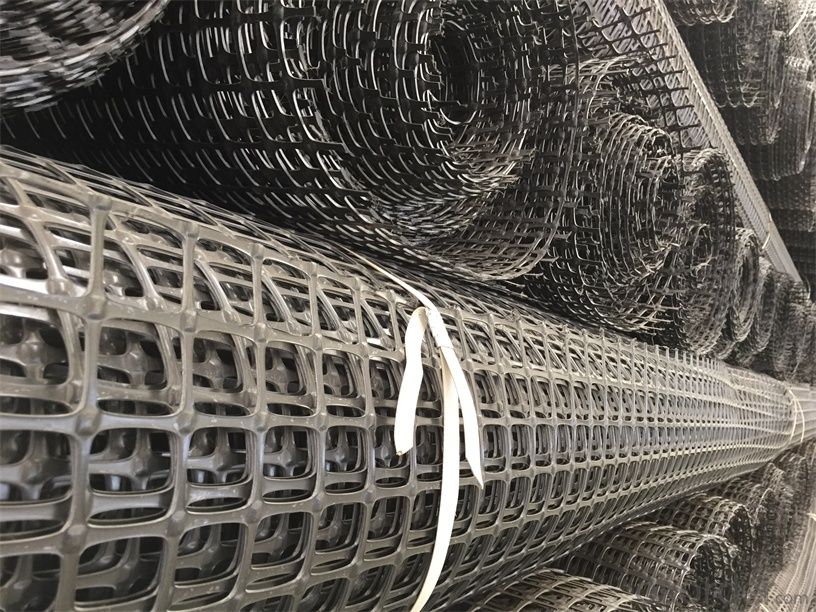

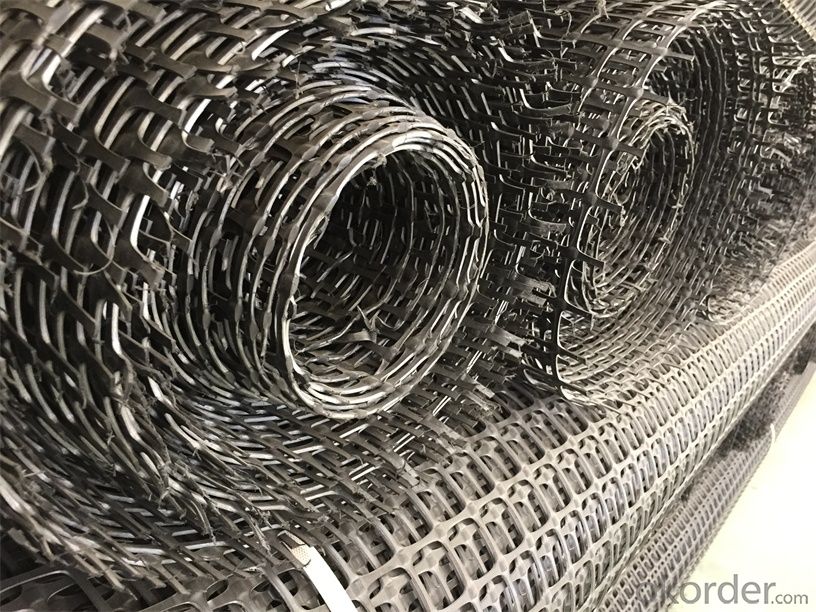

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Are geogrids effective in reducing differential settlement in foundations?

- Yes, geogrids are effective in reducing differential settlement in foundations. They provide additional reinforcement and improve the load-bearing capacity of the soil, thereby distributing the loads more evenly and reducing the differential settlement between different areas of a foundation.

- Q: Can geogrids be used in subgrade improvement?

- Yes, geogrids can be used in subgrade improvement. Geogrids are often used in civil engineering projects to reinforce and stabilize weak soils in the subgrade. They can help to distribute loads more evenly, increase bearing capacity, and reduce settlement. Additionally, geogrids can improve the overall performance and longevity of the subgrade, making them a valuable tool in subgrade improvement projects.

- Q: Can geogrids be used in ground improvement projects?

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly used to reinforce and stabilize soil, improving its bearing capacity and preventing soil erosion. They are effective in a variety of ground improvement applications such as road construction, retaining walls, and slope stabilization.

- Q: What are the long-term maintenance requirements for geogrid-reinforced structures?

- The long-term maintenance requirements for geogrid-reinforced structures typically involve periodic inspections to ensure the integrity of the structure and the geogrid. These inspections may include visual assessments, measurements, and testing to detect any signs of damage, settlement, or deterioration. Additionally, regular cleaning and removal of debris from the structure is necessary to prevent blockages or potential damage. Overall, proper maintenance and timely repairs are essential for the longevity and performance of geogrid-reinforced structures.

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- For example, geotextile, geomembrane, soft water pipes, etc.. According to the direction of the water flow, the coefficient of permeability of the geotextile is measured

- Q: What are the specifications of fiberglass geogrid for Asphalt Pavement

- 50KN is a relatively large number of glass fiber, of course, also depends on the road re design of the standard is to determine what the specifications,

- Q: I am a site using two-way 80 plastic geogrid, the need to use U type nails specifications and prices? Consultation with the construction process, thank you.Correction: two-way 80 steel plastic geogrid.

- Key points of quality technology1. The quality of geogrid conforms to the requirements of drawings or specifications.2, the laying of geogrid should be straightened straight down to the underlying layer. There should be no distortion, wrinkle, overlap, the use of artificial tension, the use of U type nails fixed on the surface of the base.3, the connection between the geogrid should be solid, its stack length is not less than 30cm.4, the surface of the soil layer should be smooth, less than 8cm geogrid Embankment Filler, the maximum particle size should not be greater than 6cm.5, the geogrid is laid in a timely manner in its fill, in order to avoid its exposure to the sun for a long time, not because of the soil geogrid.6, the filling layer paving, layered rolling. On the basis of the method, the upper subgrade filling.7, different levels of geogrid connection position should be staggered. Construction should avoid transport vehicles and other construction machinery in the shop has spread to direct rolling and tension of Geogrid on location.8, the key of laying geogrid is to ensure continuity, to avoid distortion, fold, overlap, pay special attention to avoid excessive tension, to prevent exceeding the tensile strength and deformation limit failure and tear.Steel grating 80KN bandwidth should be between 1.6-1.8cm, fixed with U nails as long as the diameter larger than this size OK, as for the price, hardware stores should have to sell, not very expensive.

- Q: Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in civil engineering projects, including pipeline construction, to reinforce and stabilize the soil. They provide additional strength and stability to the ground, reducing the risk of ground movement and potential damage to the pipelines.

- Q: What are the different testing methods for geogrids?

- There are several testing methods for geogrids, including tensile strength testing, creep testing, puncture testing, and pullout testing. These methods are used to evaluate the performance, durability, and suitability of geogrids for various applications in civil engineering and geotechnical projects.

- Q: What is the difference between geocell and geogrid

- Geocell:Product Description: geocell is made of high strength HDPE broadband, through a strong welding and the formation of a network of grid room structure. The utility model has the advantages of flexible expansion, and can be folded when being transported, and when the utility model is used, the utility model can be filled with earth and stone or concrete materials, and the structure of the utility model has the advantages of strong lateral confinement and large steel. The utility model can be used as a cushion to deal with the bearing capacity of the foundation with the soft foundation, and can also be arranged on the slope to form a slope protection structure, and can also be used for constructing the retaining structure, etc..

Send your message to us

Biaxial High Tensile Strength Warp Knitted Geogrids for Tree Protection

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords