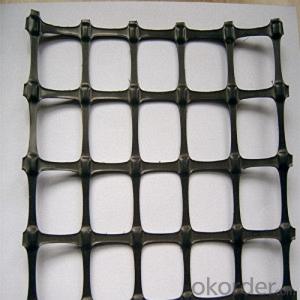

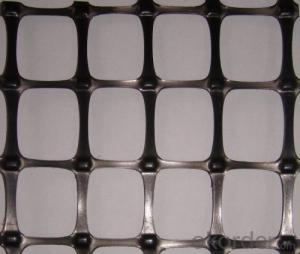

Class 4 Geotextile Fabric Biaxial Geogrids for Jetty, Road, and Tunnel Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

PET geogrid

15X15,20X20,25X25,30X30,35X35,40X40,50X50,60X60.

70X70,80X80,90X90,100X100,110X110KN

steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid 20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KNRoad bed reinforcement-it can effectively allocate and disperse load,improve the stability and load capacity of road bed and extend the useful lfe of road

color:

black

certification:

ISO9001,ISO14001

standard:

GB/T 17639-2008

MOQ:

5000m2

Place of origin:

Shandong,China

packing:

according to customer's need

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the porosity of the fabric, the size and shape of the openings or pores in the fabric, the fabric thickness, and the surface roughness of the fabric. Additionally, the type and quality of the fibers used in the geotextile can also impact its hydraulic conductivity.

- Q: Geotextile how to sampling

- Related methods can refer to GB-1998, can also go to our factory to purchase, to observe. My contact is the name of the registration. Free testing training! All the country's site can be shipped!

- Q: Are geotextiles resistant to earthquakes?

- No, geotextiles are not inherently resistant to earthquakes. While geotextiles can provide benefits in terms of soil stabilization and erosion control, they do not have the ability to withstand seismic activity on their own. Additional engineering measures and materials are required to ensure structures are earthquake resistant.

- Q: How do geotextiles help in preventing sinkhole formation?

- Geotextiles help in preventing sinkhole formation by providing a stable base for the soil and reducing the risk of erosion. They act as a barrier to prevent the movement of soil particles, thus preventing the formation of voids or cavities that can lead to sinkholes. Additionally, geotextiles can improve the overall structural integrity of the soil, enhancing its load-bearing capacity and minimizing the potential for sinkhole development.

- Q: This is a large sample of gravel anti-filter how this project count

- Visual inspection of the slope of the distance from the clay layer is equal to the thickness of the gravel layer, that is 200mm, so even if it came out scattered Simple function. Also, I used a simple method is to draw in CAD, fill, measure the area, area by length, the volume came out

- Q: What is the specific use of geotextile construction site? How much is it used?

- From the reinforcement, the role of filtration, I am specializing in the production of geotechnical materials

- Q: Do you have a geotextile bed?

- Filament geotextile can, short silk toxic, I produce geotextile materials

- Q: Can geotexters cover grass seeds?

- To be very thin very Caixing, the cost a little expensive Oh waste

- Q: What is the meaning of geotextile anchoring?

- Geotextile anchorage: is the geotextile in the construction of civil engineering construction in the slope of the fixed, to prevent the geotextile movement.

- Q: What is the role of the laying of geotextiles at the bottom of the grassland?

- From the soil and soil, fixed slope protection, anti-erosion, anti-filter (over the water, but soil) and other effects, I professional production geotextile, geomembrane and other products, wish smooth

Send your message to us

Class 4 Geotextile Fabric Biaxial Geogrids for Jetty, Road, and Tunnel Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords