Base Reinforcement Geogrids for High Density Biaxial Geogrids in Highway for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

OEM or Road

Model Number:

EGA50-50, EGA80-80, EGA100-100

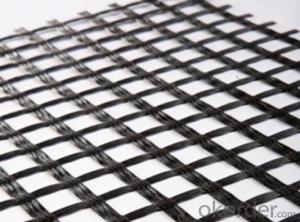

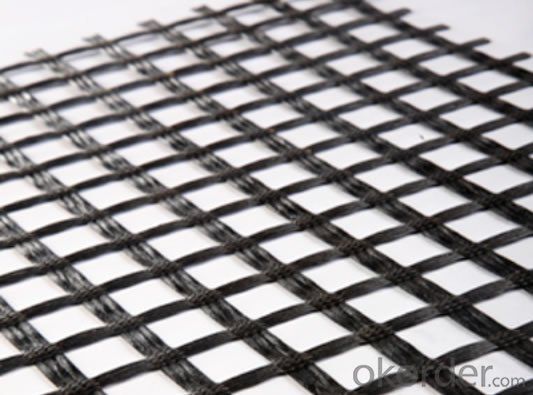

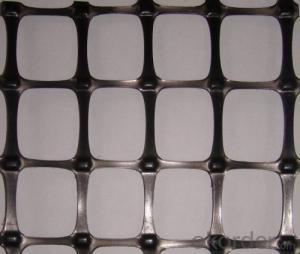

We have three types of Geogrids; extruded, woven and bonded. Extruded Geogrids are flat structures in polymer (usually high density polyethylene or polypropylene) that are extruded and then pulled: this may be done in one direction (mono-oriented geogrids), or in the two main directions (bi-oriented geogrids). They are used in soil and road paving reinforcement.

Bonded Geogrids are flat structures, where two or more series of strip elements made of polyester coated with polyethylene, are linked at regular intervals by means of bonding.

Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres, that may also be coated with a further protection layer, using synthetic material (usually PVC or other polymer).

Geogrid application filled with ground material is one of the easy of soil reinforcement. The thickness of such construction may be 50% less than the thickness of standard replacement which allows avoiding costly soil replacement.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in temporary construction haul roads?

- Yes, geogrids can be used in temporary construction haul roads. Geogrids are commonly used to reinforce road bases and improve their load-bearing capacity. They can effectively distribute the load and prevent the formation of ruts and potholes, making them suitable for temporary haul roads during construction projects.

- Q: Can geogrids be used in slope stabilization for railway embankments with high water table conditions?

- Yes, geogrids can be used in slope stabilization for railway embankments with high water table conditions. Geogrids offer effective reinforcement and soil confinement, preventing soil erosion and enhancing the stability of the embankment even in areas with high water levels. They provide additional strength and support to the soil, reducing the risk of slope failure and improving the overall stability of the railway embankment.

- Q: How do geogrids improve the performance of reinforced soil foundations?

- Geogrids improve the performance of reinforced soil foundations by providing additional tensile strength and stability to the soil. They act as a reinforcement material, dispersing the applied load more evenly and reducing the potential for settlement or lateral movement. Geogrids also help to increase the bearing capacity of the soil, preventing excessive deformation and enhancing the overall durability and longevity of the foundation.

- Q: How do geogrids help in load distribution?

- Geogrids help in load distribution by providing reinforcement and stabilization to the soil. They distribute the applied load across a wider area, reducing stress concentration on the soil. This prevents excessive settlement and deformation of the ground, improving the overall stability and load-bearing capacity of the structure.

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners in reservoirs?

- No, geogrids do not provide reinforcement to geosynthetic asphalt liners in reservoirs.

- Q: Are geogrids resistant to chemical attack from soil contaminants?

- Yes, geogrids are generally resistant to chemical attack from soil contaminants.

- Q: What is geogrid, what is the role?

- To enhance the problemGlass fiber geogrid features:The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life, can be widely used in the old cement pavement and airport runway maintenance, dams, river, slope protection, bridge pavement engineering field enhancement processing, can give the pavement reinforcement and reinforcement to prevent rutting, fatigue crack of pavement, hot and cold crack and the expansion of reflection crack, and can disperse the bearing capacity of pavement and prolong the service life of the pavement, high tensile strength and low elongation, no long-term creep, high physical and chemical stability, thermal stability, fatigue cracking, rutting resistance, cracking resistance at low temperature delay, reduce reflection crack.

- Q: Are geogrids suitable for use in ground reinforcement for residential developments?

- Yes, geogrids are suitable for use in ground reinforcement for residential developments. Geogrids provide stability and reinforcement to soil, preventing erosion and maintaining the integrity of the ground. They are commonly used in various applications, including driveways, parking areas, and retaining walls, making them a reliable choice for residential developments.

- Q: Are geogrids resistant to moisture absorption?

- Yes, geogrids are generally resistant to moisture absorption. They are designed to have low water absorption properties, which helps maintain their structural integrity and effectiveness in various applications.

- Q: What is the market price of the geotechnical grid in 2017?

- (1) the first accurate release of subgrade slope line, in order to ensure the roadbed width of each side of the widened 0.5m, soil drying good leveling by 25T after vibroll pressure two times, then 50T shock pressure of four times, how much is the uneven supply market price? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong local earthwork grid with artificial coordination. (2) 0.3m thick medium (coarse) sand, artificial with mechanical leveling, 25T vibratory roller static pressure two times. (3) geogrid, geogrid laying bottom surface should be smooth, dense, should generally be tiled, straight, no overlap, no curl, kink, two pieces of geogrid adjacent to lap 0.2m, and along the horizontal Subgrade of geogrid overlap every 1 meters with 8 wire were interspersed in the grid connection, and laying on every 1.5-2m U nail is fixed on the ground.

Send your message to us

Base Reinforcement Geogrids for High Density Biaxial Geogrids in Highway for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords