Concrete Form Plywood - Film Faced Plywood Shuttering Plywood with Good Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

| Type: | Plywoods | Place of Origin: | Shandong China (Mainland) | Brand Name: | chantaplex |

| Model Number: | film faced plywood | Usage: | Outdoor | Grade: | First-Class |

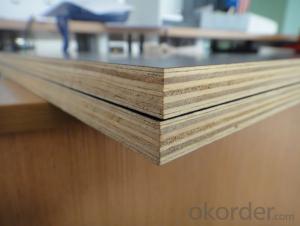

| Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | 13-Ply Boards |

| thickness: | 9mm,12mm,15mm,18mm,21mm | core: | poplar,eucalyptus,combi | size: | 1220x2440mm,1250x2500mm |

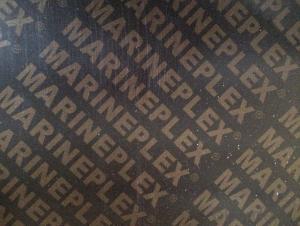

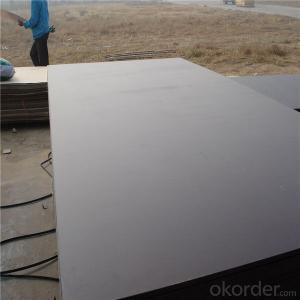

| glue: | WBP melamine phenolic | film: | black,brown, red | cycle life: | 4--20 repeated using times |

| delivery time: | within 15 days after receiving LC or deposit |

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they are very light, so film faced plywood is convenient for transporting, and only one person could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork could be cut into the required size.

3. Re-used: film faced plywood could be used 8-10 times.

4.Multi Using: film faced plywood could be used for wall, slab, column, beam and bridge concrete pouring etc..

5. No Deformation: film faced plywood is also whole but not deformation and chipp-

ing after 72 hours cooking in boiling water.

6. High Quality Film: film faced plywood is filmed by Dynea brown or black film impor-

ted, it protect the formwork surface from the corrosion and makes the formwork durable, improves the flatness of the concrete surface and makes the concrete surface save the second time plastering, so it could save a lot cost of construction.

Packaging & Delivery

| Packaging Detail: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

| Delivery Detail: | within 15 days after receiving LC or deposit |

- Q: Plywood in the material defects?

- race of the parasitic plant marks of parasitic plants formed by the parasitic plants or rotten plants penetrate the wood and the formation of small groups of small channels

- Q: The difference between the multilayer board and the plywood is as follows

- Also available for aircraft, ships, trains, cars, construction and packaging board and other materials.

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- moisture content. Between 12 and 14% (according to Chinese national standards, Ⅰ, Ⅱ plywood absolute moisture content of not more than 13%;

- Q: Why plywood is cheaper than solid wood

- commonly known as: multi-layer board) is one of the commonly used furniture materials, is a wood-based panel. Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other

- Q: Multilayer plywood with what method is fixed

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

- Q: A brief introduction to plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Plywood in the decoration works how to use

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood.

- Q: Solid wood and plywood which is better?

- Can not completely determine which is better, this depends on how you use the main.

Send your message to us

Concrete Form Plywood - Film Faced Plywood Shuttering Plywood with Good Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords